6FTFS-42tpd Flour Mill Plant with Rollers and 2 Years Spare Parts

-

$80000.00≥1 set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

- Port:

- tianjin

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 20 Set/Sets per Year |

|---|---|

| Payment Type: | L/C,Western Union,T/T,cash |

| Port: | tianjin |

Product Description

Product Description

Product Overview

6FTFS-42tpd flour mill plant with rollers and two years spare parts

China Hongdefa Machinery supply high quality complete line turnkey 42ton per day wheat flour milling machine with Newest technology for each part,the wheat flour milling plant have five sections as below:

2:Our price is factory price,no agent commission.Price directly you got from Factory.Factory price for wheat flour milling plant.

3:Our after sale service is best,branch factory in Addis Ababa.

Pre-clean-Cleaning section-Sifter,Milling section-Packing section-Control section.

The popular capacity is 6FTFS-42tpd flour mill plant with rollers and two years spare parts,that means process 42t raw wheat per 24hours.

1:Our machine quality is best,with cleaning-milling-packing.

1:Our machine quality is best,with cleaning-milling-packing.

Stainless steel pipes and cyclone,More durable and longlife

Smart touch screen control system,Easy control and one touch start

The machine use newest technology,special design for Africa market.The machine more durable and life long.

2:Our price is factory price,no agent commission.Price directly you got from Factory.Factory price for wheat flour milling plant.

3:Our after sale service is best,branch factory in Addis Ababa.

Two year spare part,machine guarantee is two years.And whole life service.

Food processing can never be out of business.

Wheat, depending on their protein content, is classified as soft wheat, medium hard wheat and hard wheat.And one of the ways you could enter in that never-ending cycle is by supplying flour for making bread, biscuits,cake and pasta.

But if you intend to supply graded flour, you would have to take care of wheat cleaning and wheat conditioning prior to milling.

Wheat cleaning involves grading of the wheat according to certain characteristics and blending some grades to obtain the desired flour.

Wheat conditioning involves adding a certain quantity of water, and allowing the prepared wheat to stand for several hours. Then the actual milling process begins to produce flour, wheat germ and bran.

The flour is then bagged and usually stored for several days to age prior to delivery to makers of biscuits, pasta, crackers, and other baked goods.

You can also sell the bran and wheat germ to makers of breakfast cereals or animal feeds.

6FTFS-42tpd flour mill plant with rollers and two years spare parts

Hongdefa had built a lot Turnkey wheat flour plant Projects all over the world.

We're devoted to supply tailor-made Turnkey Project, including project design, manufacture, delivery, installation and testing, worker training, aftersale service.

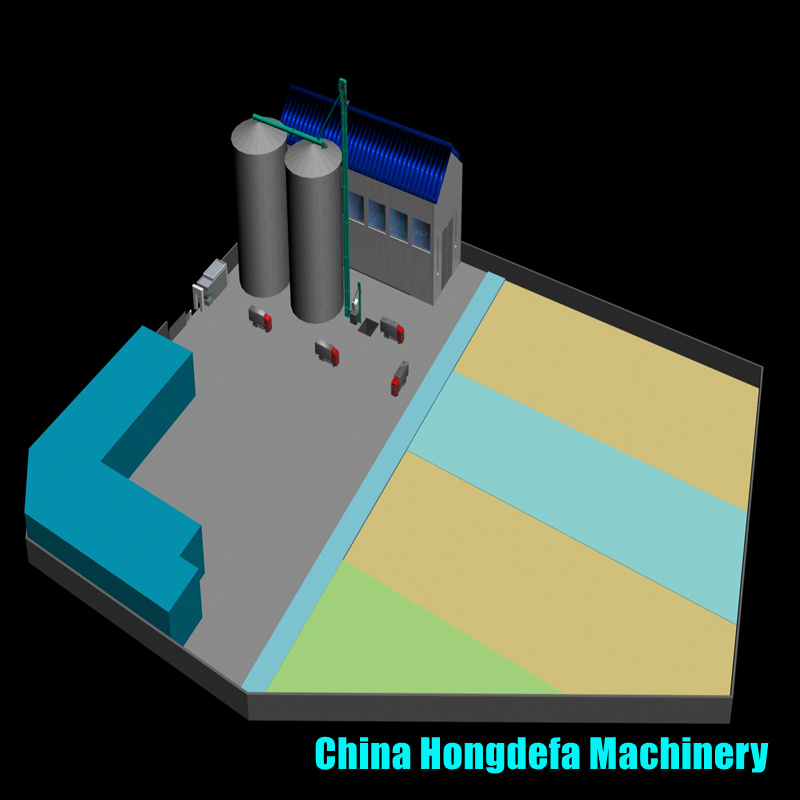

For wheat flour milling plant factory normally including below parts:

wheat flour mill plant Steel Storage Silo: Storage raw material 500t 1000t 5000t etc...

wheat flour mill plant Weighing bridge : 60t 80t

wheat flour mill plant processing: Milling machine line systems

wheat flour mill plant Packing system : PP woven bags and paper bags

wheat flour mill plant Transformer: Different transformer according machine inquiry

wheat flour mill plant Gernerator:Different Generator according machine inquiry

wheat flour mill plant Labolatory machines: Gulten machine, moisture machine, flour sieve machine etc..

PRODUCT SPECIFICATIONS

No | Item | Data |

1 | Power | 180KW forfull 6FTFS-42tpd flour mill plant with rollers and two years spare parts |

2 | Capacity | full automatic 6FTFS-42tpd flour mill plant with rollers and two years spare parts |

3 | Line | Turnkey project |

4 | Main Systems | Cleaning-milling-packing |

5 | Products | Grade 1 flour/Semolina |

6 | By products | Bran for animal feed |

7 | Operation | Fully Automatic |

8 | Output | 75%-80% according flour quality inquiry |

PRODUCT CONFIGURATION

wheat flour milling plant-High standard Roller Mill.

The roller mill is the core part of the milling line, there are different kinds and different standards roller mills.the higher quality of the machine is the more durable the machine will be, so is the flour quality

wheat flour milling plant-Double sifter.

The flour sifters have double-bin sifters, and the sifter can be made from different quality wood, which decides the quality too.

wheat flour milling plant-PLC control.

Computer control system

One touch Start

Fully automatic Control

Easy operate

Successful Project

300t/24h Wheat Flour Milling plant in Afghanistan

300t/24h Wheat Flour Milling plant in Malasiya

250t/24h Wheat Flour Milling plant in Egypt

120t/24h Wheat Flour Milling plant in Ethiopia

82t/24h Wheat Flour Milling plant in Ethiopia

120t/24h Wheat Flour Milling plant in Ethiopia

About our service

China Hongdefa Machinery 50ton per day wheat flour milling machine

1. Pre-sales Consultation

We can design the processing technology according to your requirements.

Even go to your city for discussing face to face.

2. Hongdefa Flour Mil Installation

Our professional technicians offer the guidance of installation, commissioning the machines,build up the workshop building and silos,and we can also help to reform the old workshop building as per customers’ condition.

3. Reliable Hongdefa Industrial Wheat Flour Milling Machine Quality

Best quality plant for longer working time.

Steel stainless pipes for food protection and longer working time.

PLC control system with Intelligent control all the machines.

4. Training

Our professional technicians provides training workers of customers’ factory,which is helpful to guarantee the normal operation of the equipment and reduce its downtime. In this way, the quality of finished products will be guaranteed.

5. Fixing and Maintenance

Our professional technical team can help solve any problem that occurs in customer’s flour production efficiently.

We can do regular examinations to the equipment and offer you guidance on the equipment operation if you need.

Our staff in Addis Ababa,Ethiopia; Kampala,Uganda; Lusaka,Zambia Office can go to see your site and machines directly and give some advise face to face.

6. Spare Parts Supply

Normally we will send you some wearing parts available for two-year operation of the equipment in our first order.

When you are in need of new spare parts in the future, we can send directly from Addis Ababa/Ethiopia,Kampala/Uganda,Lusaka/Zambia Office timely

where have put a big storage room and delivery door to door.

if you want to buy the high standard with reasonable price , send me your inquiry to us, our design can meet all of your needs.

pls let me know plan, thanks.

Why Choose Hongdefa

Related Keywords

Related Keywords

You May Also Like

You May Also Like