The application of large electromagnetic stirrer

- Delivery Time:

- 4 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

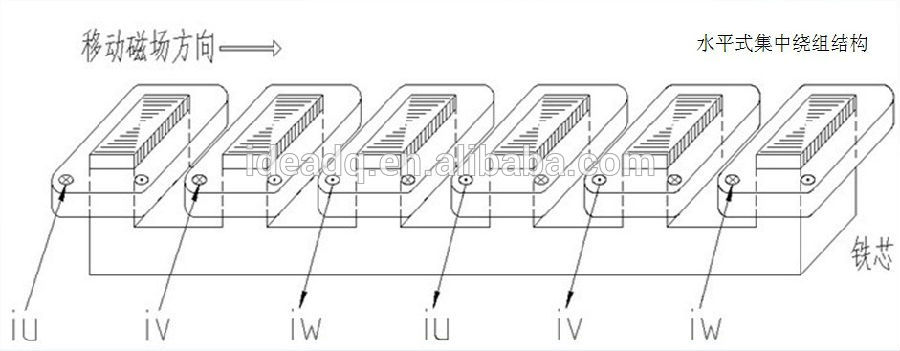

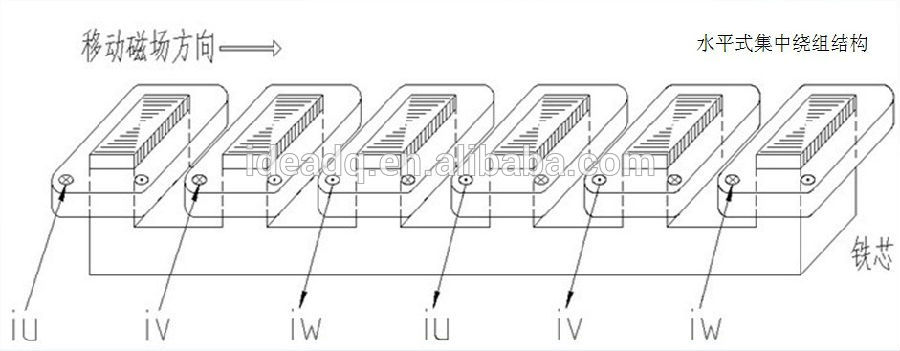

The application of electromagnetic stirring In the primary aluminum used in the production process of electromagnetic stirring technology the most main purpose is to make the aluminum alloy melt liquid components uniform, and on the waste recycling technology’s main purpose is to improve the melting effect, to reduce the loss and increase casting yield. Of course, since the noise components of the waste aluminum was more complex, long time mixing for composition adjustment and composition of the improved uniformity is particularly important. We shall, according to the different purpose reasonable setting of electromagnet stirring device installation position sensors, either party furnace, the furnace, single room or double room furnace, the installation of sensors can kind of wan, buy the installation is mainly used for the new furnace form or depth of molten pool in the production process change the big furnace, this form melting liquid depth change effects and can achieve good mixing effect, in waste recycling aluminum furnace installation position to deviation furnace center, so can form the whole furnace big, help to fast melting scrap aluminum. Sensors installed side is mainly used for old furnace way transformation and molten pool depth in the production process change less than 200 mm. Of electromagnetic stirring Electromagnetic Stirrer is composed of AC-DC-AC inverters, inductors, pure water-cooled devices (water-wind type), functional trolley and appurtenances. The function of AC-DC-AC inverters is to convert 50/60Hz industry frequency alternate current (AC) into a 0.5 ~ 5.0Hz, 3-phase low-frequency power. The power through sensor coil, will produce a traveling magnetic field, which penetrating stainless steel plate of the bottom of furnace and lining effect on molten aluminum, make molten aluminum regular movement, finally achieved the purpose of even stirring. By changing the voltage, frequency and phase of the variable frequency power supply, you can change the magnitude and direction of the stirring force.  With the economic development our country is from a big to a strong aluminium country, both from the product categories and product quality are required to have a qualitative leap, to do a good job, must first sharpen his device, so our furnace technology changes with each passing day, form a complete set of equipment technical also requires synchro. “Energy saving, green environmental protection” become the core topics in today and forever, so electromagnetic stirring on the original application effect to really make a big improvement that is energy saving from the device itself, if electromagnetic stirring in their own breakthrough on core subject equipment first, that are inductors and power supply. The core of the inductor is efficiency of magnetic field, to enhance the efficiency of the magnetic field means that the input power reduction, the two key factors directly effecting the efficiency and magnetic field, one is the magnetic medium, the other is the winding structure. The magnetic medium (medium flux loop), including the inductor iron core, bottom material and molten metal. We use silicon steel sheet in the inductor’s iron core, because of its high saturated magnetic induction intensity, less wastage, at present in the applications of magnetic materials industry is the preferred material. Bottom material used is stainless steel and refractory material, relative permeability of these two kinds of material is 1, no matter from furnace body structure strength and magnetic circuit are irreplaceable, so from the magnetic circuit of the sensor material, combined with refractory silicon steel sheet or stainless steel window from the technical point of view is irreplaceable, it is difficult to break. There are two forms on the inductor winding structures, one is the horizontal concentrated winding, inland mostly adopts this type; Secondly, the structure of vertical concentrated winding, ABB use this structure, no matter what kind of structure form, It’s theoretical basis the following linear magnetic circuit calculation of cramer's rule, just install fixed in a different way. The advantages of horizontal concentrated winding: Facilitate the installation of the winding and fixed, and vertical effective magnetic field and have high utilization rate, and when destructive occurs in the winding is convenient for application field to replacement and maintenance, will not directly affect the customer production. The advantages of vertical concentrated winding: Can narrow the width appearance sensors then narrow stainless steel window size. Shortcoming: This way for electric winding, due to the vertical direction of main magnetic circuit level stress is bigger, bring difficulty for winding is fixed, the short circuit failure rate will increase between the layers and turn-to-turn, this kind of structure is not convenient to application field of replacement and maintenance. So in the new type of AC-DC-AC inductor’s structure, our company still uses the horizontal concentrated winding structure. To sum up, for the inductor, no matter from magnetic media or winding structure, at present it is difficult to have a big span to improve the efficiency of the magnetic field, in order to reduce the input power to achieve energy saving effect. Now from technical point of view can really solve electromagnetic stirring of energy conservation and environmental protection technology core is how to reduce the equipment installed power, improve the efficiency of power supply, improve the power supply output waveform to enhances the working efficiency of the sensor, this prompted aluminium smelters electromagnetic stirring to solve the problem of power generation fundamentally, that is how to make domestic AC-DC-AC power supply applied to aluminium smelters electromagnetic stirring.

With the economic development our country is from a big to a strong aluminium country, both from the product categories and product quality are required to have a qualitative leap, to do a good job, must first sharpen his device, so our furnace technology changes with each passing day, form a complete set of equipment technical also requires synchro. “Energy saving, green environmental protection” become the core topics in today and forever, so electromagnetic stirring on the original application effect to really make a big improvement that is energy saving from the device itself, if electromagnetic stirring in their own breakthrough on core subject equipment first, that are inductors and power supply. The core of the inductor is efficiency of magnetic field, to enhance the efficiency of the magnetic field means that the input power reduction, the two key factors directly effecting the efficiency and magnetic field, one is the magnetic medium, the other is the winding structure. The magnetic medium (medium flux loop), including the inductor iron core, bottom material and molten metal. We use silicon steel sheet in the inductor’s iron core, because of its high saturated magnetic induction intensity, less wastage, at present in the applications of magnetic materials industry is the preferred material. Bottom material used is stainless steel and refractory material, relative permeability of these two kinds of material is 1, no matter from furnace body structure strength and magnetic circuit are irreplaceable, so from the magnetic circuit of the sensor material, combined with refractory silicon steel sheet or stainless steel window from the technical point of view is irreplaceable, it is difficult to break. There are two forms on the inductor winding structures, one is the horizontal concentrated winding, inland mostly adopts this type; Secondly, the structure of vertical concentrated winding, ABB use this structure, no matter what kind of structure form, It’s theoretical basis the following linear magnetic circuit calculation of cramer's rule, just install fixed in a different way. The advantages of horizontal concentrated winding: Facilitate the installation of the winding and fixed, and vertical effective magnetic field and have high utilization rate, and when destructive occurs in the winding is convenient for application field to replacement and maintenance, will not directly affect the customer production. The advantages of vertical concentrated winding: Can narrow the width appearance sensors then narrow stainless steel window size. Shortcoming: This way for electric winding, due to the vertical direction of main magnetic circuit level stress is bigger, bring difficulty for winding is fixed, the short circuit failure rate will increase between the layers and turn-to-turn, this kind of structure is not convenient to application field of replacement and maintenance. So in the new type of AC-DC-AC inductor’s structure, our company still uses the horizontal concentrated winding structure. To sum up, for the inductor, no matter from magnetic media or winding structure, at present it is difficult to have a big span to improve the efficiency of the magnetic field, in order to reduce the input power to achieve energy saving effect. Now from technical point of view can really solve electromagnetic stirring of energy conservation and environmental protection technology core is how to reduce the equipment installed power, improve the efficiency of power supply, improve the power supply output waveform to enhances the working efficiency of the sensor, this prompted aluminium smelters electromagnetic stirring to solve the problem of power generation fundamentally, that is how to make domestic AC-DC-AC power supply applied to aluminium smelters electromagnetic stirring.

With the economic development our country is from a big to a strong aluminium country, both from the product categories and product quality are required to have a qualitative leap, to do a good job, must first sharpen his device, so our furnace technology changes with each passing day, form a complete set of equipment technical also requires synchro. “Energy saving, green environmental protection” become the core topics in today and forever, so electromagnetic stirring on the original application effect to really make a big improvement that is energy saving from the device itself, if electromagnetic stirring in their own breakthrough on core subject equipment first, that are inductors and power supply. The core of the inductor is efficiency of magnetic field, to enhance the efficiency of the magnetic field means that the input power reduction, the two key factors directly effecting the efficiency and magnetic field, one is the magnetic medium, the other is the winding structure. The magnetic medium (medium flux loop), including the inductor iron core, bottom material and molten metal. We use silicon steel sheet in the inductor’s iron core, because of its high saturated magnetic induction intensity, less wastage, at present in the applications of magnetic materials industry is the preferred material. Bottom material used is stainless steel and refractory material, relative permeability of these two kinds of material is 1, no matter from furnace body structure strength and magnetic circuit are irreplaceable, so from the magnetic circuit of the sensor material, combined with refractory silicon steel sheet or stainless steel window from the technical point of view is irreplaceable, it is difficult to break. There are two forms on the inductor winding structures, one is the horizontal concentrated winding, inland mostly adopts this type; Secondly, the structure of vertical concentrated winding, ABB use this structure, no matter what kind of structure form, It’s theoretical basis the following linear magnetic circuit calculation of cramer's rule, just install fixed in a different way. The advantages of horizontal concentrated winding: Facilitate the installation of the winding and fixed, and vertical effective magnetic field and have high utilization rate, and when destructive occurs in the winding is convenient for application field to replacement and maintenance, will not directly affect the customer production. The advantages of vertical concentrated winding: Can narrow the width appearance sensors then narrow stainless steel window size. Shortcoming: This way for electric winding, due to the vertical direction of main magnetic circuit level stress is bigger, bring difficulty for winding is fixed, the short circuit failure rate will increase between the layers and turn-to-turn, this kind of structure is not convenient to application field of replacement and maintenance. So in the new type of AC-DC-AC inductor’s structure, our company still uses the horizontal concentrated winding structure. To sum up, for the inductor, no matter from magnetic media or winding structure, at present it is difficult to have a big span to improve the efficiency of the magnetic field, in order to reduce the input power to achieve energy saving effect. Now from technical point of view can really solve electromagnetic stirring of energy conservation and environmental protection technology core is how to reduce the equipment installed power, improve the efficiency of power supply, improve the power supply output waveform to enhances the working efficiency of the sensor, this prompted aluminium smelters electromagnetic stirring to solve the problem of power generation fundamentally, that is how to make domestic AC-DC-AC power supply applied to aluminium smelters electromagnetic stirring.

With the economic development our country is from a big to a strong aluminium country, both from the product categories and product quality are required to have a qualitative leap, to do a good job, must first sharpen his device, so our furnace technology changes with each passing day, form a complete set of equipment technical also requires synchro. “Energy saving, green environmental protection” become the core topics in today and forever, so electromagnetic stirring on the original application effect to really make a big improvement that is energy saving from the device itself, if electromagnetic stirring in their own breakthrough on core subject equipment first, that are inductors and power supply. The core of the inductor is efficiency of magnetic field, to enhance the efficiency of the magnetic field means that the input power reduction, the two key factors directly effecting the efficiency and magnetic field, one is the magnetic medium, the other is the winding structure. The magnetic medium (medium flux loop), including the inductor iron core, bottom material and molten metal. We use silicon steel sheet in the inductor’s iron core, because of its high saturated magnetic induction intensity, less wastage, at present in the applications of magnetic materials industry is the preferred material. Bottom material used is stainless steel and refractory material, relative permeability of these two kinds of material is 1, no matter from furnace body structure strength and magnetic circuit are irreplaceable, so from the magnetic circuit of the sensor material, combined with refractory silicon steel sheet or stainless steel window from the technical point of view is irreplaceable, it is difficult to break. There are two forms on the inductor winding structures, one is the horizontal concentrated winding, inland mostly adopts this type; Secondly, the structure of vertical concentrated winding, ABB use this structure, no matter what kind of structure form, It’s theoretical basis the following linear magnetic circuit calculation of cramer's rule, just install fixed in a different way. The advantages of horizontal concentrated winding: Facilitate the installation of the winding and fixed, and vertical effective magnetic field and have high utilization rate, and when destructive occurs in the winding is convenient for application field to replacement and maintenance, will not directly affect the customer production. The advantages of vertical concentrated winding: Can narrow the width appearance sensors then narrow stainless steel window size. Shortcoming: This way for electric winding, due to the vertical direction of main magnetic circuit level stress is bigger, bring difficulty for winding is fixed, the short circuit failure rate will increase between the layers and turn-to-turn, this kind of structure is not convenient to application field of replacement and maintenance. So in the new type of AC-DC-AC inductor’s structure, our company still uses the horizontal concentrated winding structure. To sum up, for the inductor, no matter from magnetic media or winding structure, at present it is difficult to have a big span to improve the efficiency of the magnetic field, in order to reduce the input power to achieve energy saving effect. Now from technical point of view can really solve electromagnetic stirring of energy conservation and environmental protection technology core is how to reduce the equipment installed power, improve the efficiency of power supply, improve the power supply output waveform to enhances the working efficiency of the sensor, this prompted aluminium smelters electromagnetic stirring to solve the problem of power generation fundamentally, that is how to make domestic AC-DC-AC power supply applied to aluminium smelters electromagnetic stirring.

Related Keywords

Related Keywords

You May Also Like

You May Also Like