Large tonnage of electromagnetic stirrer

- Delivery Time:

- 4 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

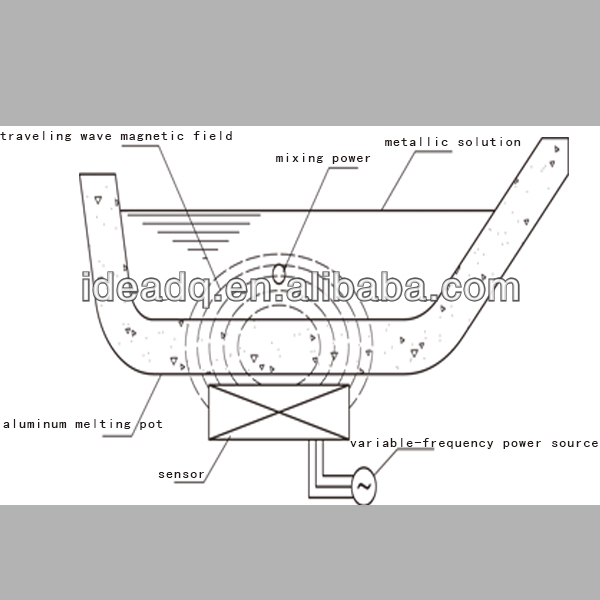

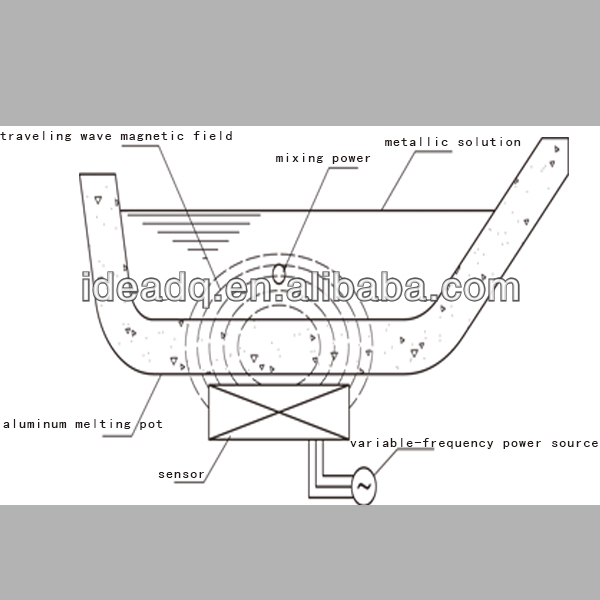

Effect of stirring To adopt the advanced technology of electromagnetic stirring, through lots of experiments and industrial production at home and abroad by using electromagnetic stirring main effect achieved: Reducing slag content; Reduce the center shrinkage cavity; Eliminate the macrosegregation; Increase the equiaxial crystal ratio; Improve solidification organization, etc.  Compared with other mixing way, electromagnetic stirring compatible with the other mixing way’ advantages, and has its own unique characteristic, therefore, electromagnetic stirring has become the common use stirring method. The advantages of electromagnetic stirring Our company is professional producing the 2-150 tons of various kinds of specifications with aluminum melting pot electromagnetic stirring device, is the non-ferrous metal industry electromagnetic products professional manufacturers and suppliers, the product series: furnace bottom inductive electromagnetic stirring device, lateral inductive electromagnetic stirring device, renewable aluminum industry with double room furnace electromagnetic blender, etc. Electromagnetic stirring technology application can be obtained as follows effect: 1. Can make the melt alloy components uniform. General electromagnetic stirring device (no more than 20 minutes), can the whole furnace of various elements of the aluminium chemical composition of the relative deviation is less than 5%, can satisfy the almost all alloy to composition uniformity of the requirements. 2. The mixing process not destroy the oxidation layer, can reduce the melt hydrogen absorbing and oxygen, ensure the quality of the melt, and reduce the loss (relative value) 20 to 25%. 3. Can make the top and bottom of the melt temperature uniformity. General mixing ten minutes to the limit of the melt temperature can drop to less than 5 °C. So can reduce melting temperature, can improve the melt bottom alloying melting degree, in lower melting again at the same time can reduce the degree of damage. 4. In the process of aluminum ingots re-melting using electromagnetic stirring technology can shorten the time of smelting, improve work efficiency, reduce energy consumption, according to data provided by the already, can reduce energy consumption (improve efficiency) 20 to 30%. 5. No pollution aluminum melting liquid. This has the important meaning for high purity aluminium and the iron control strict alloy. 6. Can reduce the labor intensity, and improve working con

Compared with other mixing way, electromagnetic stirring compatible with the other mixing way’ advantages, and has its own unique characteristic, therefore, electromagnetic stirring has become the common use stirring method. The advantages of electromagnetic stirring Our company is professional producing the 2-150 tons of various kinds of specifications with aluminum melting pot electromagnetic stirring device, is the non-ferrous metal industry electromagnetic products professional manufacturers and suppliers, the product series: furnace bottom inductive electromagnetic stirring device, lateral inductive electromagnetic stirring device, renewable aluminum industry with double room furnace electromagnetic blender, etc. Electromagnetic stirring technology application can be obtained as follows effect: 1. Can make the melt alloy components uniform. General electromagnetic stirring device (no more than 20 minutes), can the whole furnace of various elements of the aluminium chemical composition of the relative deviation is less than 5%, can satisfy the almost all alloy to composition uniformity of the requirements. 2. The mixing process not destroy the oxidation layer, can reduce the melt hydrogen absorbing and oxygen, ensure the quality of the melt, and reduce the loss (relative value) 20 to 25%. 3. Can make the top and bottom of the melt temperature uniformity. General mixing ten minutes to the limit of the melt temperature can drop to less than 5 °C. So can reduce melting temperature, can improve the melt bottom alloying melting degree, in lower melting again at the same time can reduce the degree of damage. 4. In the process of aluminum ingots re-melting using electromagnetic stirring technology can shorten the time of smelting, improve work efficiency, reduce energy consumption, according to data provided by the already, can reduce energy consumption (improve efficiency) 20 to 30%. 5. No pollution aluminum melting liquid. This has the important meaning for high purity aluminium and the iron control strict alloy. 6. Can reduce the labor intensity, and improve working con

Compared with other mixing way, electromagnetic stirring compatible with the other mixing way’ advantages, and has its own unique characteristic, therefore, electromagnetic stirring has become the common use stirring method. The advantages of electromagnetic stirring Our company is professional producing the 2-150 tons of various kinds of specifications with aluminum melting pot electromagnetic stirring device, is the non-ferrous metal industry electromagnetic products professional manufacturers and suppliers, the product series: furnace bottom inductive electromagnetic stirring device, lateral inductive electromagnetic stirring device, renewable aluminum industry with double room furnace electromagnetic blender, etc. Electromagnetic stirring technology application can be obtained as follows effect: 1. Can make the melt alloy components uniform. General electromagnetic stirring device (no more than 20 minutes), can the whole furnace of various elements of the aluminium chemical composition of the relative deviation is less than 5%, can satisfy the almost all alloy to composition uniformity of the requirements. 2. The mixing process not destroy the oxidation layer, can reduce the melt hydrogen absorbing and oxygen, ensure the quality of the melt, and reduce the loss (relative value) 20 to 25%. 3. Can make the top and bottom of the melt temperature uniformity. General mixing ten minutes to the limit of the melt temperature can drop to less than 5 °C. So can reduce melting temperature, can improve the melt bottom alloying melting degree, in lower melting again at the same time can reduce the degree of damage. 4. In the process of aluminum ingots re-melting using electromagnetic stirring technology can shorten the time of smelting, improve work efficiency, reduce energy consumption, according to data provided by the already, can reduce energy consumption (improve efficiency) 20 to 30%. 5. No pollution aluminum melting liquid. This has the important meaning for high purity aluminium and the iron control strict alloy. 6. Can reduce the labor intensity, and improve working con

Compared with other mixing way, electromagnetic stirring compatible with the other mixing way’ advantages, and has its own unique characteristic, therefore, electromagnetic stirring has become the common use stirring method. The advantages of electromagnetic stirring Our company is professional producing the 2-150 tons of various kinds of specifications with aluminum melting pot electromagnetic stirring device, is the non-ferrous metal industry electromagnetic products professional manufacturers and suppliers, the product series: furnace bottom inductive electromagnetic stirring device, lateral inductive electromagnetic stirring device, renewable aluminum industry with double room furnace electromagnetic blender, etc. Electromagnetic stirring technology application can be obtained as follows effect: 1. Can make the melt alloy components uniform. General electromagnetic stirring device (no more than 20 minutes), can the whole furnace of various elements of the aluminium chemical composition of the relative deviation is less than 5%, can satisfy the almost all alloy to composition uniformity of the requirements. 2. The mixing process not destroy the oxidation layer, can reduce the melt hydrogen absorbing and oxygen, ensure the quality of the melt, and reduce the loss (relative value) 20 to 25%. 3. Can make the top and bottom of the melt temperature uniformity. General mixing ten minutes to the limit of the melt temperature can drop to less than 5 °C. So can reduce melting temperature, can improve the melt bottom alloying melting degree, in lower melting again at the same time can reduce the degree of damage. 4. In the process of aluminum ingots re-melting using electromagnetic stirring technology can shorten the time of smelting, improve work efficiency, reduce energy consumption, according to data provided by the already, can reduce energy consumption (improve efficiency) 20 to 30%. 5. No pollution aluminum melting liquid. This has the important meaning for high purity aluminium and the iron control strict alloy. 6. Can reduce the labor intensity, and improve working con

Related Keywords

Related Keywords

You May Also Like

You May Also Like