Semi-solid experiment electromagnetic stirrer

- Delivery Time:

- 4 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

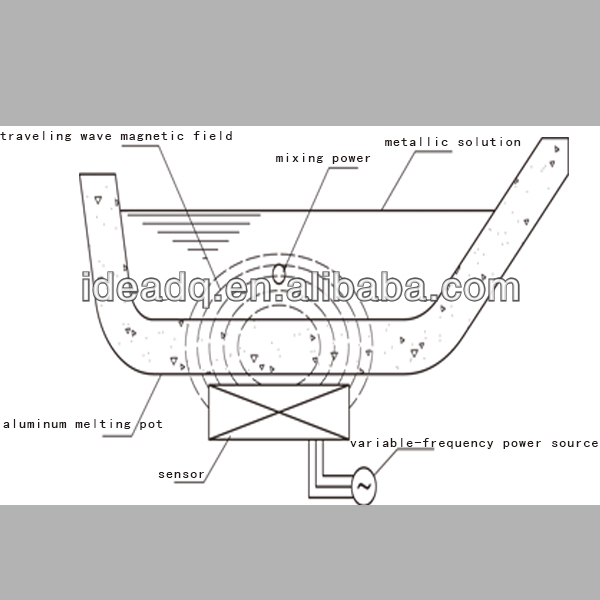

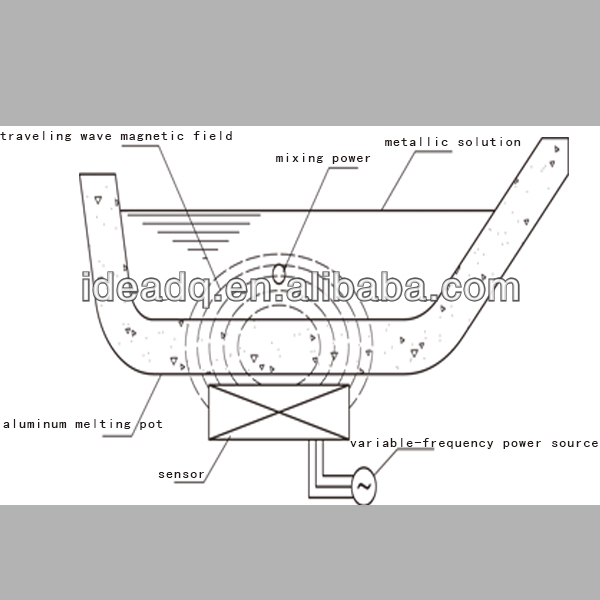

The action principle of the diagram below:  Product basic information Inductive electromagnetic stirring device is a kind of application principle of electromagnetic induction and produce a magnetic field in the role of molten aluminium liquid so that melting liquid has regular exercise equipment. In the electromagnetic stirring subject device-to low frequency current of sensors, in order to form the traveling wave alternating magnetic field, melting liquid in the influence of the magnetic field ofpotentialand current, the induced current and magnetic fields interact to produce the electromagnetic force, make the melting liquid regular exercise, in order to achieve the purpose of mixing. By changing the direction of the field and the traveling wave strength, can effectively regulate the melting liquid mixing direction and stir intensity. System Over View: 1.The system adopts IPM intelligent power module as the core device, itself has a short circuit, over-current, overheating, under-voltage protection function, in the design of the system add a reliable buffer circuit and other anti-interference circuit. 2.Using industrial-grade single-chip computer as core control, it can be adapted to the harsh industrial field, data collection is accurately, processing speed is fast. 3.Switch, contactor, rectifier, filter, buffer circuits and other electronic devices, all choose the reliable device, in the design choose the larger pressure, flow, coefficient of thermal protection. 4.As far as possible in the structure design and manufacturing to reduce the distributed capacitance and inductance and raise resistance to radiation, induction and coupling interference ability. 5.Parameters and program design strictness, system logic inputs and downtime, can better prevent system damage caused by the error operation and forced outage.

Product basic information Inductive electromagnetic stirring device is a kind of application principle of electromagnetic induction and produce a magnetic field in the role of molten aluminium liquid so that melting liquid has regular exercise equipment. In the electromagnetic stirring subject device-to low frequency current of sensors, in order to form the traveling wave alternating magnetic field, melting liquid in the influence of the magnetic field ofpotentialand current, the induced current and magnetic fields interact to produce the electromagnetic force, make the melting liquid regular exercise, in order to achieve the purpose of mixing. By changing the direction of the field and the traveling wave strength, can effectively regulate the melting liquid mixing direction and stir intensity. System Over View: 1.The system adopts IPM intelligent power module as the core device, itself has a short circuit, over-current, overheating, under-voltage protection function, in the design of the system add a reliable buffer circuit and other anti-interference circuit. 2.Using industrial-grade single-chip computer as core control, it can be adapted to the harsh industrial field, data collection is accurately, processing speed is fast. 3.Switch, contactor, rectifier, filter, buffer circuits and other electronic devices, all choose the reliable device, in the design choose the larger pressure, flow, coefficient of thermal protection. 4.As far as possible in the structure design and manufacturing to reduce the distributed capacitance and inductance and raise resistance to radiation, induction and coupling interference ability. 5.Parameters and program design strictness, system logic inputs and downtime, can better prevent system damage caused by the error operation and forced outage.  Range of application A Aluminum, magnesium alloy experiments stirring B Semi-solid forming studding C course of crystallization experimental study D die-cast formation E Foam metal forming F Metal refining mixing

Range of application A Aluminum, magnesium alloy experiments stirring B Semi-solid forming studding C course of crystallization experimental study D die-cast formation E Foam metal forming F Metal refining mixing

Product basic information Inductive electromagnetic stirring device is a kind of application principle of electromagnetic induction and produce a magnetic field in the role of molten aluminium liquid so that melting liquid has regular exercise equipment. In the electromagnetic stirring subject device-to low frequency current of sensors, in order to form the traveling wave alternating magnetic field, melting liquid in the influence of the magnetic field ofpotentialand current, the induced current and magnetic fields interact to produce the electromagnetic force, make the melting liquid regular exercise, in order to achieve the purpose of mixing. By changing the direction of the field and the traveling wave strength, can effectively regulate the melting liquid mixing direction and stir intensity. System Over View: 1.The system adopts IPM intelligent power module as the core device, itself has a short circuit, over-current, overheating, under-voltage protection function, in the design of the system add a reliable buffer circuit and other anti-interference circuit. 2.Using industrial-grade single-chip computer as core control, it can be adapted to the harsh industrial field, data collection is accurately, processing speed is fast. 3.Switch, contactor, rectifier, filter, buffer circuits and other electronic devices, all choose the reliable device, in the design choose the larger pressure, flow, coefficient of thermal protection. 4.As far as possible in the structure design and manufacturing to reduce the distributed capacitance and inductance and raise resistance to radiation, induction and coupling interference ability. 5.Parameters and program design strictness, system logic inputs and downtime, can better prevent system damage caused by the error operation and forced outage.

Product basic information Inductive electromagnetic stirring device is a kind of application principle of electromagnetic induction and produce a magnetic field in the role of molten aluminium liquid so that melting liquid has regular exercise equipment. In the electromagnetic stirring subject device-to low frequency current of sensors, in order to form the traveling wave alternating magnetic field, melting liquid in the influence of the magnetic field ofpotentialand current, the induced current and magnetic fields interact to produce the electromagnetic force, make the melting liquid regular exercise, in order to achieve the purpose of mixing. By changing the direction of the field and the traveling wave strength, can effectively regulate the melting liquid mixing direction and stir intensity. System Over View: 1.The system adopts IPM intelligent power module as the core device, itself has a short circuit, over-current, overheating, under-voltage protection function, in the design of the system add a reliable buffer circuit and other anti-interference circuit. 2.Using industrial-grade single-chip computer as core control, it can be adapted to the harsh industrial field, data collection is accurately, processing speed is fast. 3.Switch, contactor, rectifier, filter, buffer circuits and other electronic devices, all choose the reliable device, in the design choose the larger pressure, flow, coefficient of thermal protection. 4.As far as possible in the structure design and manufacturing to reduce the distributed capacitance and inductance and raise resistance to radiation, induction and coupling interference ability. 5.Parameters and program design strictness, system logic inputs and downtime, can better prevent system damage caused by the error operation and forced outage.  Range of application A Aluminum, magnesium alloy experiments stirring B Semi-solid forming studding C course of crystallization experimental study D die-cast formation E Foam metal forming F Metal refining mixing

Range of application A Aluminum, magnesium alloy experiments stirring B Semi-solid forming studding C course of crystallization experimental study D die-cast formation E Foam metal forming F Metal refining mixing Related Keywords

Related Keywords

You May Also Like

You May Also Like