AF series vertical centrifugal abrasion resistant slurry froth pump

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

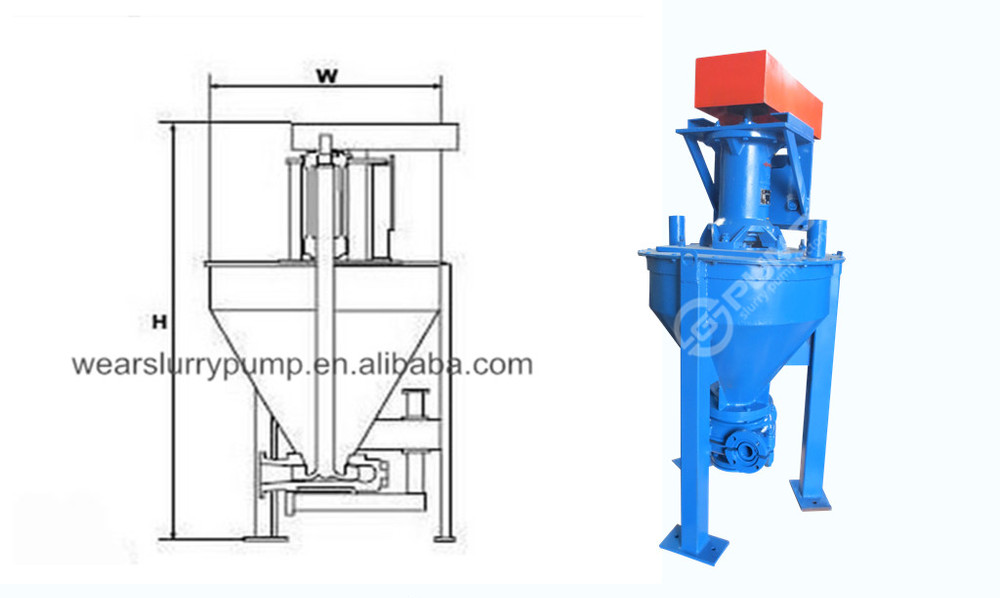

AF series vertical centrifugal abrasion resistant slurry froth pump Product Introduction 1.1 AF series vertical centrifugal abrasion resistant slurry froth pump Application: Heavy Duty Centrifugal Vertical Sump Pump belongs to our MV/ MVR series slurry pump, which can run under insufficient suction condition. They could be applied in chemical treatment, municipal wastewater control, mining, metallurgical plant, power plant, petrochemical, building material, coal washing and general industrial sectors. They play important roles in mineral processing and slurry handling, such as hydrocyclone feeding, filter press feeding, flotation feeding, magnetic separator feeding, vibrating sieve feeding, underflow control , tailings handling, etc.

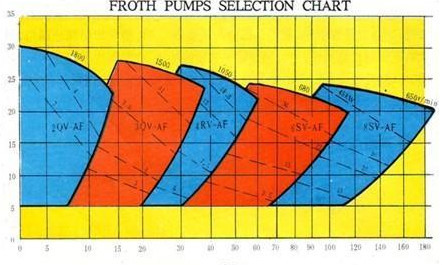

1.2 AF series vertical centrifugal abrasion resistant slurry froth pump Feature: Outlet: 1-14 inch

1.2 AF series vertical centrifugal abrasion resistant slurry froth pump Feature: Outlet: 1-14 inch

Capacity: to 3060 m³/h

Head: to 80 m

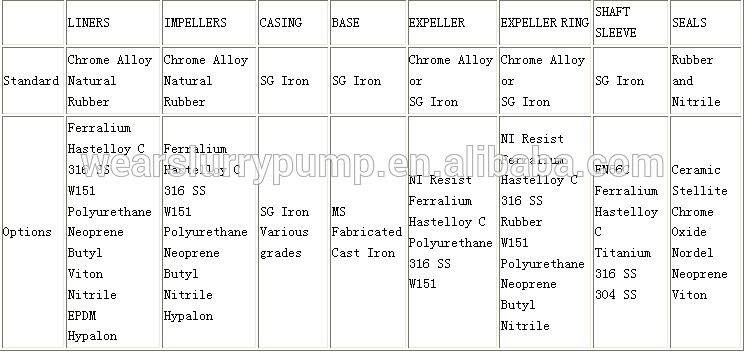

Wet Parts Materials:High chromium alloy or natural rubber Type: Centrifugal, Vertical, Single/Double Casing

Replacement: Interchangeable with other pumps dimensionally 1.3 AF series vertical centrifugal abrasion resistant slurry froth pump Model Explanation: 65QV-SPR 65: Discharge diameter (mm) QV: The type of bearing assembly SP: vertical type slurry pump R: rubber lining

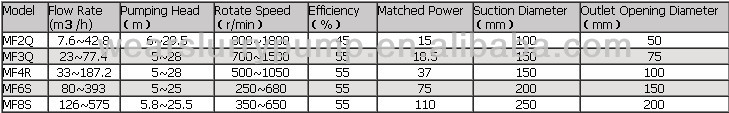

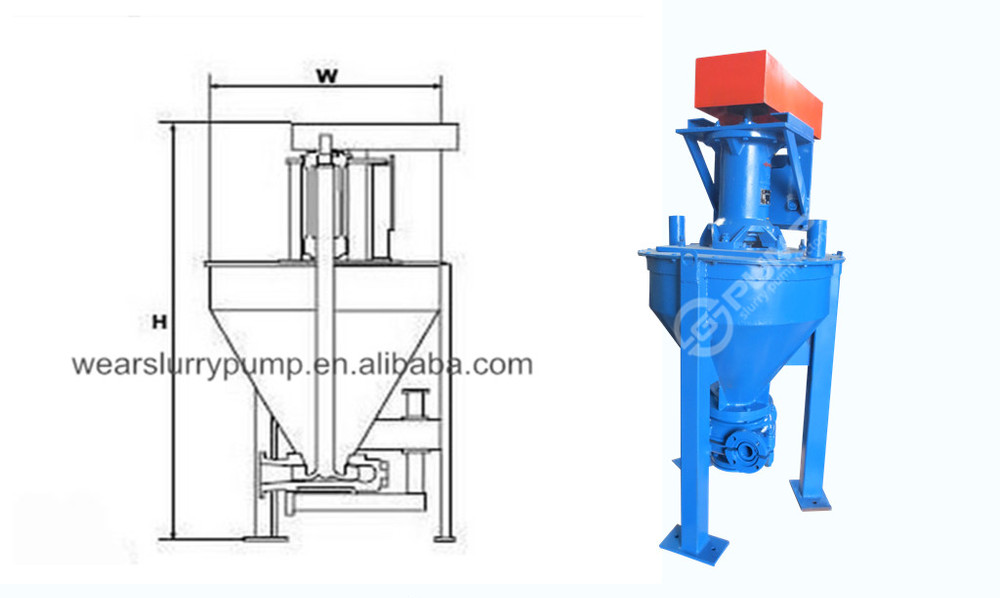

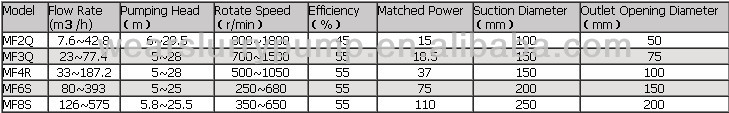

1.4 AF series vertical centrifugal abrasion resistant slurry froth pump Structure: vertical slurry pumps include MF bearing assembly type and so on.

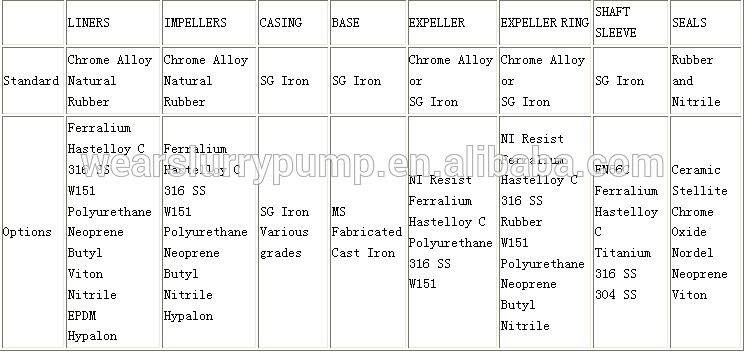

1.4 AF series vertical centrifugal abrasion resistant slurry froth pump Structure: vertical slurry pumps include MF bearing assembly type and so on.  1.5 AF series vertical centrifugal abrasion resistant slurry froth pump component:

1.5 AF series vertical centrifugal abrasion resistant slurry froth pump component:

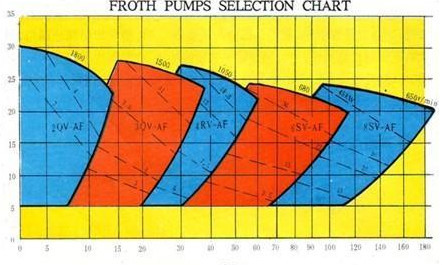

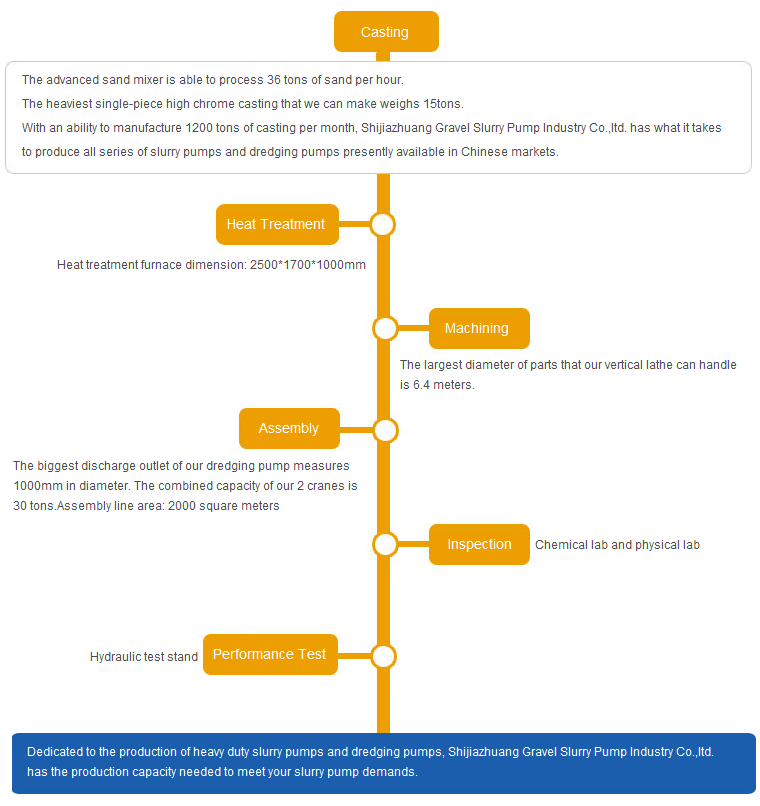

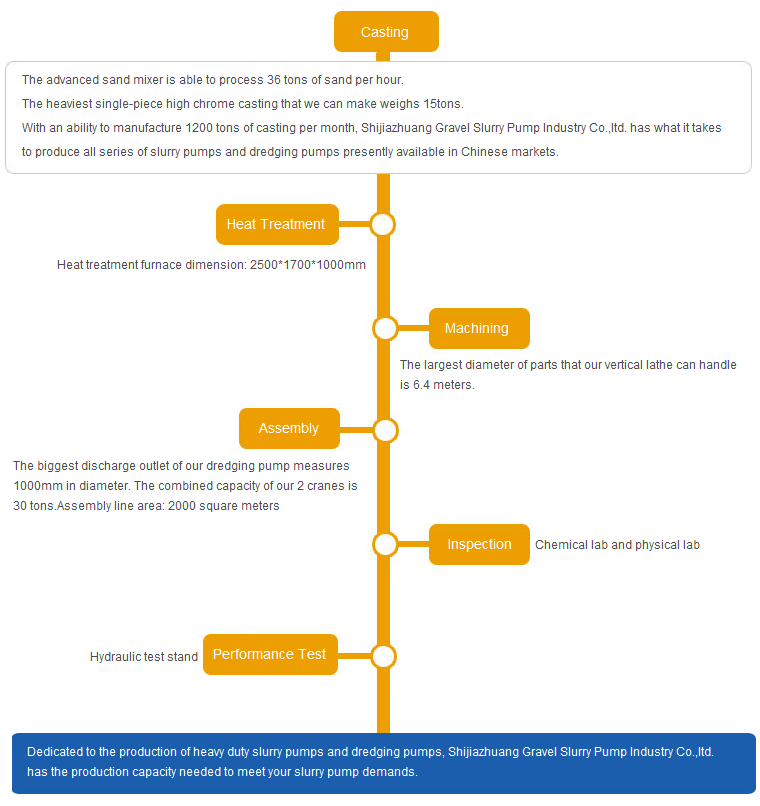

2.1 Work flow Chart

2.1 Work flow Chart

2.2 Successful Case

2.2 Successful Case

2.3 Package and shipping

2.3 Package and shipping  3.1 Service Stock Availability

3.1 Service Stock Availability

A comprehensive range of pumps & spares are held in stock to meet immediate requirements. Traceability

All parts are submitted to a rigorous quality control and for many parts machining of critical parts is performed in house. All processes are logged ensuring 100% traceability from foundry to end user. Expertise

Trained and experienced product specialists with expertise in handling the complete range of SlurryPro products. Technical Support

Full technical information covering all aspects of pump performance including compatibility with materials and system designs. Advice

Reliable advice regarding pump unit assembly, installation, operation, preventative maintenance programming and spare parts inventory. Service Support

Full repair and service capabilities including scheduled servicing. Quality Control

SlurryPro pumps are manufactured strictly in accordance with the requirements of ISO 9001:2008 to ensure the highest levels of product quality. Replacement Parts

SlurryPro offers a wide range of interchangeable replacement spare parts to suit most common brand slurry pumps o Impellers - hard metal and elastomer o Casing liners - hard metal and elastomer o Shaft units o Bearings o Seals and Sealing System 3.2 Our team and contact us Shijiazhuang Gravel Slurry Pump Industry Co.,ltd TEL: +86-311-85026467

FAX: +86-311-83050889 Email: sales3(at)gsslurrypump(dot)com skype :slurrypumptrade wechat/whatapp :0086-13694098282

1.2 AF series vertical centrifugal abrasion resistant slurry froth pump Feature: Outlet: 1-14 inch

1.2 AF series vertical centrifugal abrasion resistant slurry froth pump Feature: Outlet: 1-14 inchCapacity: to 3060 m³/h

Head: to 80 m

Wet Parts Materials:High chromium alloy or natural rubber Type: Centrifugal, Vertical, Single/Double Casing

Replacement: Interchangeable with other pumps dimensionally 1.3 AF series vertical centrifugal abrasion resistant slurry froth pump Model Explanation: 65QV-SPR 65: Discharge diameter (mm) QV: The type of bearing assembly SP: vertical type slurry pump R: rubber lining

1.4 AF series vertical centrifugal abrasion resistant slurry froth pump Structure: vertical slurry pumps include MF bearing assembly type and so on.

1.4 AF series vertical centrifugal abrasion resistant slurry froth pump Structure: vertical slurry pumps include MF bearing assembly type and so on.  1.5 AF series vertical centrifugal abrasion resistant slurry froth pump component:

1.5 AF series vertical centrifugal abrasion resistant slurry froth pump component:

2.1 Work flow Chart

2.1 Work flow Chart

2.2 Successful Case

2.2 Successful Case

2.3 Package and shipping

2.3 Package and shipping  3.1 Service Stock Availability

3.1 Service Stock AvailabilityA comprehensive range of pumps & spares are held in stock to meet immediate requirements. Traceability

All parts are submitted to a rigorous quality control and for many parts machining of critical parts is performed in house. All processes are logged ensuring 100% traceability from foundry to end user. Expertise

Trained and experienced product specialists with expertise in handling the complete range of SlurryPro products. Technical Support

Full technical information covering all aspects of pump performance including compatibility with materials and system designs. Advice

Reliable advice regarding pump unit assembly, installation, operation, preventative maintenance programming and spare parts inventory. Service Support

Full repair and service capabilities including scheduled servicing. Quality Control

SlurryPro pumps are manufactured strictly in accordance with the requirements of ISO 9001:2008 to ensure the highest levels of product quality. Replacement Parts

SlurryPro offers a wide range of interchangeable replacement spare parts to suit most common brand slurry pumps o Impellers - hard metal and elastomer o Casing liners - hard metal and elastomer o Shaft units o Bearings o Seals and Sealing System 3.2 Our team and contact us Shijiazhuang Gravel Slurry Pump Industry Co.,ltd TEL: +86-311-85026467

FAX: +86-311-83050889 Email: sales3(at)gsslurrypump(dot)com skype :slurrypumptrade wechat/whatapp :0086-13694098282

Related Keywords

Related Keywords

You May Also Like

You May Also Like