vertical electric chrome filter equipment slurry pump

- Delivery Time:

- 3 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

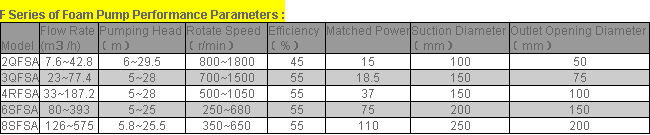

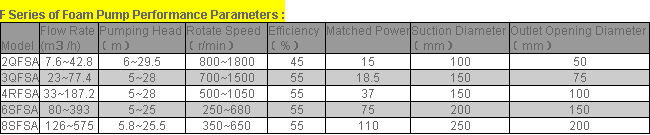

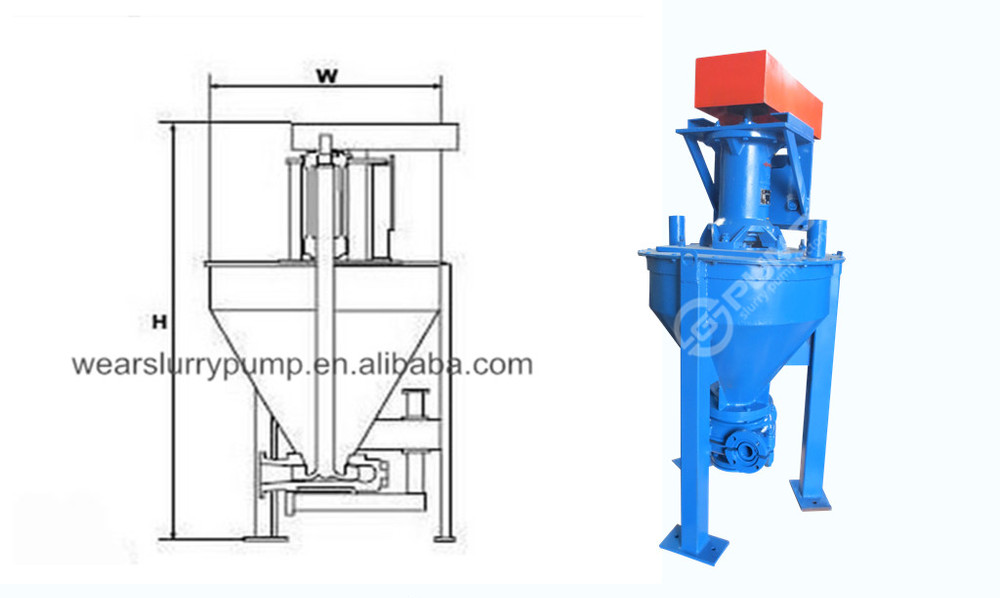

Vertical electric chrome filter froth slurry pump Product Description F series froth pump is a newly type generation product that be researched and developed on the basis of bringing and absorbing the advanced technology from both home and abroad. The company made continuous efforts to marketing this series of pump, and now they are widely applied in metallurgy, coal mining, chemical and other industrial sectors. The products are suitable for pumping abrasive and erosive slurry and bubbles and foams. This series of pump can effectively eliminate the foams and bubbles out of the slurry during the operation. Even the feed-in material is not enough, the pump can still work normally, which especially applied in various of flotation process, it is an ideal pump product for conveying foam type slurry.  Foam Slurry Pump Perfomance:

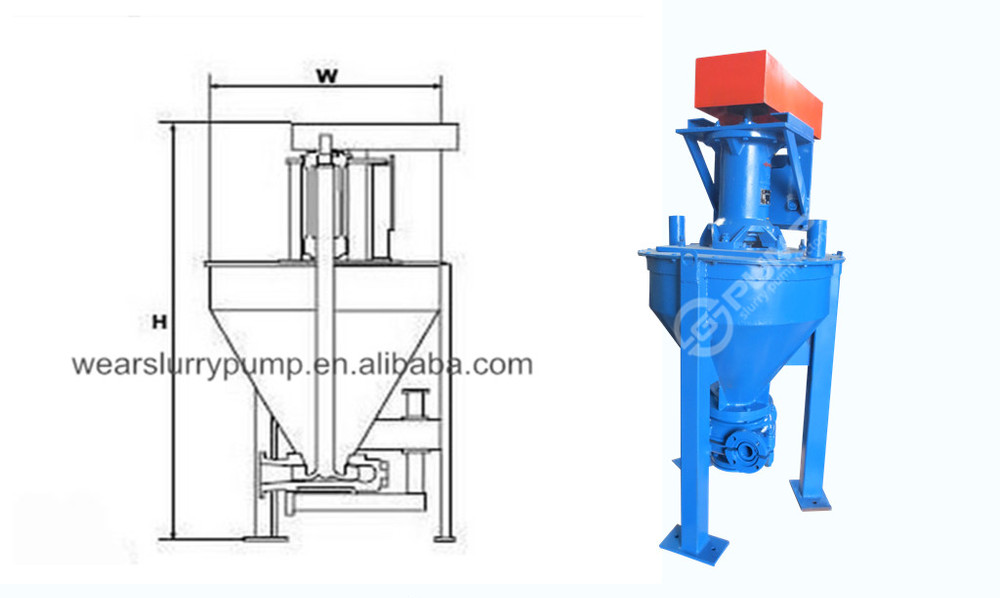

Foam Slurry Pump Perfomance:  Froth pump features The froth pump head use double shell structure, the flow-parts use hard nickel, high chromium or rubber material, and its driving section is universal with SP(R) type pump. Hopper charging box use steel plate structure, liner plate can be covered if the conveying media required, and the pump outlet opening position can be interval changed by 45°. This series of pump can effectively eliminate the foams and bubbles out of the slurry during the operation. Even the feed-in material is not enough, the pump can still work normally. Vertical Froth Pump Structure

Froth pump features The froth pump head use double shell structure, the flow-parts use hard nickel, high chromium or rubber material, and its driving section is universal with SP(R) type pump. Hopper charging box use steel plate structure, liner plate can be covered if the conveying media required, and the pump outlet opening position can be interval changed by 45°. This series of pump can effectively eliminate the foams and bubbles out of the slurry during the operation. Even the feed-in material is not enough, the pump can still work normally. Vertical Froth Pump Structure

Spare parts Bearing assembly - a large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame. Liners - easily replaceable liners are bolted, not glued, to the casing for positive attachment and east of maintance. Hard metal liners are completely interchangeable with pressure molded elastomer. Elastomer seal ring back all liner joints. Casing - Casing halves of cast or ductile iron with exernal reinforcing ribs provide high operating pressure capabilities and extra measure of safety. Impeller - front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomrer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available. Throatbush - wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal. Pump Base - a very robust onepiece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance

Spare parts Bearing assembly - a large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame. Liners - easily replaceable liners are bolted, not glued, to the casing for positive attachment and east of maintance. Hard metal liners are completely interchangeable with pressure molded elastomer. Elastomer seal ring back all liner joints. Casing - Casing halves of cast or ductile iron with exernal reinforcing ribs provide high operating pressure capabilities and extra measure of safety. Impeller - front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomrer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available. Throatbush - wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal. Pump Base - a very robust onepiece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance

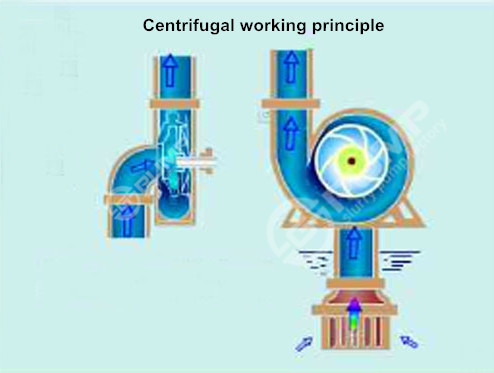

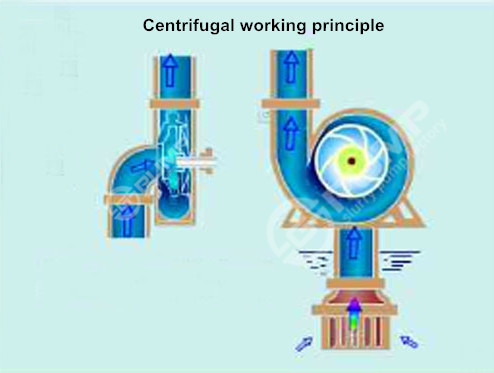

Application Horizontal centrifugal mining slurry pump is widely used in transport slurry with slurry with strong corrosive proof and high concentration for many industries such as metallurgy, mine, coal, electric power, building materials and so on.

Application Horizontal centrifugal mining slurry pump is widely used in transport slurry with slurry with strong corrosive proof and high concentration for many industries such as metallurgy, mine, coal, electric power, building materials and so on.

Processing&Workshop Slurry pump's processing

Processing&Workshop Slurry pump's processing  Slurry pump's Workshop We have first class production equipment.There are more than 100sets of equipment,such as lost foam casting profuction line,shot blast machine,heat treatment furnace,CNClathe,digital display large vertical lathe,digital display horizontal milling machine etc.

Slurry pump's Workshop We have first class production equipment.There are more than 100sets of equipment,such as lost foam casting profuction line,shot blast machine,heat treatment furnace,CNClathe,digital display large vertical lathe,digital display horizontal milling machine etc.  Packaging & Shipping We package our slurry pumps and parts with plastic cloth inside and waterproof outside. The wooden cases are export standard. Also we have professional workers to do these cases. We are very near to Tianjin port, so it is comfortable to deliver anytime, also can save the cost.

Packaging & Shipping We package our slurry pumps and parts with plastic cloth inside and waterproof outside. The wooden cases are export standard. Also we have professional workers to do these cases. We are very near to Tianjin port, so it is comfortable to deliver anytime, also can save the cost.

Our Services 1.Any inquires will be replied within 8 working hours.2.Professional centrifugal pump manufacturer, welcome to visit our website (on-line store) and factory. 3.Customized design is available, OEM and ODM are welcomed. 4.High quality, reasonable & competitive price. 5.Fast lead time, 5-25days for bulk pump production. 6.After-sale service: all centrifugal pumps will have been strictly quality checked in house before packing. All centrifugal pumps will be well packed as request before shipping.

Our Services 1.Any inquires will be replied within 8 working hours.2.Professional centrifugal pump manufacturer, welcome to visit our website (on-line store) and factory. 3.Customized design is available, OEM and ODM are welcomed. 4.High quality, reasonable & competitive price. 5.Fast lead time, 5-25days for bulk pump production. 6.After-sale service: all centrifugal pumps will have been strictly quality checked in house before packing. All centrifugal pumps will be well packed as request before shipping.  FAQ 1.Q:Are you a factory or trading company? A:We are a factory.

FAQ 1.Q:Are you a factory or trading company? A:We are a factory.

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Shijiazhuang City, Hebei Province, China.You can fly to Shijiazhuang airport directly.All our clients, from home or abroad, are warmly welcome to visit us! 3.Q:What is The material of your products? A: The material is High chrome alloy or Rubber. We can also choose material as customers’ requirement.

4.Q:How can I get some samples?

A: We are honored to offer you samples.

5.Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end. Our factory has 15~20QC. Welcome to contact us!

Foam Slurry Pump Perfomance:

Foam Slurry Pump Perfomance:  Froth pump features The froth pump head use double shell structure, the flow-parts use hard nickel, high chromium or rubber material, and its driving section is universal with SP(R) type pump. Hopper charging box use steel plate structure, liner plate can be covered if the conveying media required, and the pump outlet opening position can be interval changed by 45°. This series of pump can effectively eliminate the foams and bubbles out of the slurry during the operation. Even the feed-in material is not enough, the pump can still work normally. Vertical Froth Pump Structure

Froth pump features The froth pump head use double shell structure, the flow-parts use hard nickel, high chromium or rubber material, and its driving section is universal with SP(R) type pump. Hopper charging box use steel plate structure, liner plate can be covered if the conveying media required, and the pump outlet opening position can be interval changed by 45°. This series of pump can effectively eliminate the foams and bubbles out of the slurry during the operation. Even the feed-in material is not enough, the pump can still work normally. Vertical Froth Pump Structure

Spare parts Bearing assembly - a large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame. Liners - easily replaceable liners are bolted, not glued, to the casing for positive attachment and east of maintance. Hard metal liners are completely interchangeable with pressure molded elastomer. Elastomer seal ring back all liner joints. Casing - Casing halves of cast or ductile iron with exernal reinforcing ribs provide high operating pressure capabilities and extra measure of safety. Impeller - front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomrer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available. Throatbush - wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal. Pump Base - a very robust onepiece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance

Spare parts Bearing assembly - a large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame. Liners - easily replaceable liners are bolted, not glued, to the casing for positive attachment and east of maintance. Hard metal liners are completely interchangeable with pressure molded elastomer. Elastomer seal ring back all liner joints. Casing - Casing halves of cast or ductile iron with exernal reinforcing ribs provide high operating pressure capabilities and extra measure of safety. Impeller - front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomrer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available. Throatbush - wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal. Pump Base - a very robust onepiece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance

Application Horizontal centrifugal mining slurry pump is widely used in transport slurry with slurry with strong corrosive proof and high concentration for many industries such as metallurgy, mine, coal, electric power, building materials and so on.

Application Horizontal centrifugal mining slurry pump is widely used in transport slurry with slurry with strong corrosive proof and high concentration for many industries such as metallurgy, mine, coal, electric power, building materials and so on.

Processing&Workshop Slurry pump's processing

Processing&Workshop Slurry pump's processing  Slurry pump's Workshop We have first class production equipment.There are more than 100sets of equipment,such as lost foam casting profuction line,shot blast machine,heat treatment furnace,CNClathe,digital display large vertical lathe,digital display horizontal milling machine etc.

Slurry pump's Workshop We have first class production equipment.There are more than 100sets of equipment,such as lost foam casting profuction line,shot blast machine,heat treatment furnace,CNClathe,digital display large vertical lathe,digital display horizontal milling machine etc.  Packaging & Shipping We package our slurry pumps and parts with plastic cloth inside and waterproof outside. The wooden cases are export standard. Also we have professional workers to do these cases. We are very near to Tianjin port, so it is comfortable to deliver anytime, also can save the cost.

Packaging & Shipping We package our slurry pumps and parts with plastic cloth inside and waterproof outside. The wooden cases are export standard. Also we have professional workers to do these cases. We are very near to Tianjin port, so it is comfortable to deliver anytime, also can save the cost.

Our Services 1.Any inquires will be replied within 8 working hours.2.Professional centrifugal pump manufacturer, welcome to visit our website (on-line store) and factory. 3.Customized design is available, OEM and ODM are welcomed. 4.High quality, reasonable & competitive price. 5.Fast lead time, 5-25days for bulk pump production. 6.After-sale service: all centrifugal pumps will have been strictly quality checked in house before packing. All centrifugal pumps will be well packed as request before shipping.

Our Services 1.Any inquires will be replied within 8 working hours.2.Professional centrifugal pump manufacturer, welcome to visit our website (on-line store) and factory. 3.Customized design is available, OEM and ODM are welcomed. 4.High quality, reasonable & competitive price. 5.Fast lead time, 5-25days for bulk pump production. 6.After-sale service: all centrifugal pumps will have been strictly quality checked in house before packing. All centrifugal pumps will be well packed as request before shipping.  FAQ 1.Q:Are you a factory or trading company? A:We are a factory.

FAQ 1.Q:Are you a factory or trading company? A:We are a factory.2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Shijiazhuang City, Hebei Province, China.You can fly to Shijiazhuang airport directly.All our clients, from home or abroad, are warmly welcome to visit us! 3.Q:What is The material of your products? A: The material is High chrome alloy or Rubber. We can also choose material as customers’ requirement.

4.Q:How can I get some samples?

A: We are honored to offer you samples.

5.Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end. Our factory has 15~20QC. Welcome to contact us!

Related Keywords

Related Keywords

You May Also Like

You May Also Like