pump to dredge navigable canals

- Delivery Time:

- 5 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Company Information Shijiazhuang Gravel Slurry Pump Industry Co.,ltd locates in Shijiazhuang, Hebei Province,China, it is an integrative production, research, design and sales company, specialized in manufacturing slurry pump products. The company acting as one of the national heavy machinery industry unit, now has been developed into a professional manufacturer of slurry pump, mud pump, slush pump, foam pump, sand-slurry pump. pump to dredge navigable canals  Advantage of our slurry pump: Competitive price; short lead time; powerful technical support for pump selection and problem solving Product Features MG detailed specification 1. Advanced hydraulic dredging pump model, CAD 3D design, high efficiency and obvious energy-saving 2. Large dredging sand depth, high density of dredging mud, good pump NPSH and strong suction lift ability. 3. Strong through-put. The dredging pump can persistently discharge gravel, high plastic soil lump,etc. 4.The dredging pump can be directly matched with either motor or diesel engine. 5. Wide application. The dredging pump can be used in various kinds of soil quality. Generally,the dredge pump is matched with an impeller with 3 or 5 pieces of vane. At the same time,the impellers can be provided with various diameters and vane types to suit kinds of working conditions. 6. Little hydraulic loss, high efficiency and low oil-consumption. 7. Little volume, light weight. 8. Steady operating, little vibration, low noise. 9. Simple & reliable constrution, easily disassembly & assembly,convenient maintainc 10. Reliable sealing without leakage. 11. Long operating life of parts

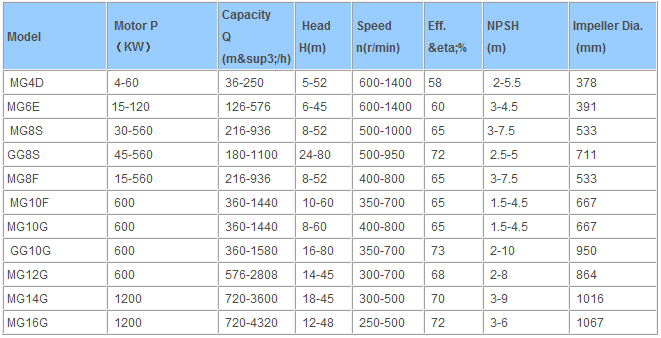

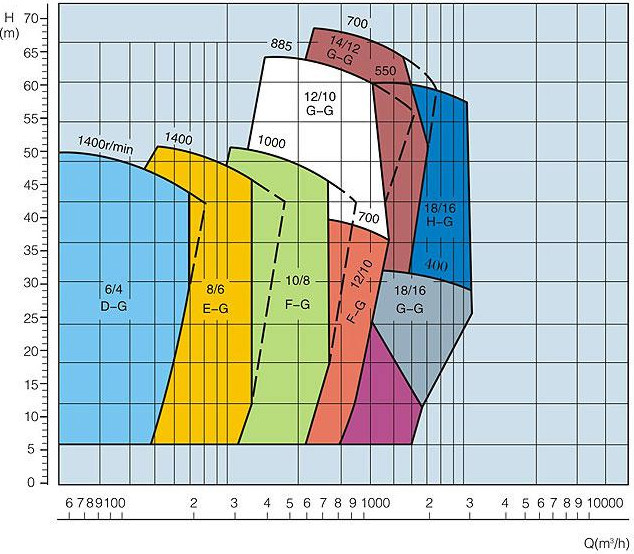

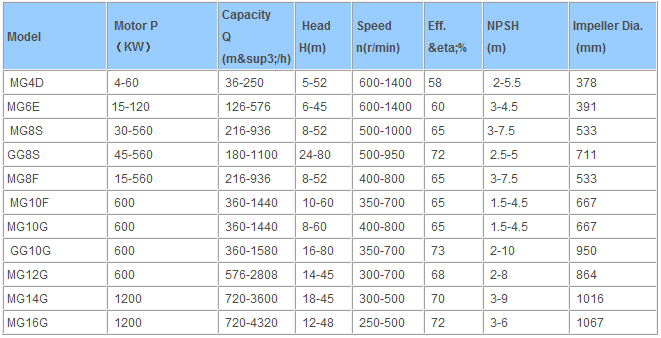

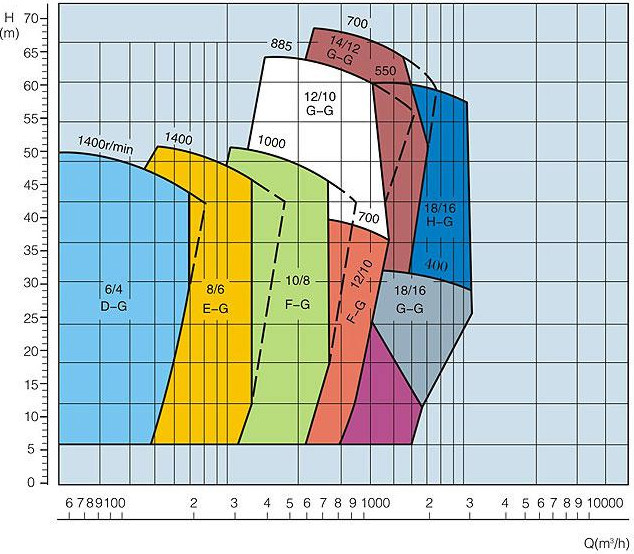

Advantage of our slurry pump: Competitive price; short lead time; powerful technical support for pump selection and problem solving Product Features MG detailed specification 1. Advanced hydraulic dredging pump model, CAD 3D design, high efficiency and obvious energy-saving 2. Large dredging sand depth, high density of dredging mud, good pump NPSH and strong suction lift ability. 3. Strong through-put. The dredging pump can persistently discharge gravel, high plastic soil lump,etc. 4.The dredging pump can be directly matched with either motor or diesel engine. 5. Wide application. The dredging pump can be used in various kinds of soil quality. Generally,the dredge pump is matched with an impeller with 3 or 5 pieces of vane. At the same time,the impellers can be provided with various diameters and vane types to suit kinds of working conditions. 6. Little hydraulic loss, high efficiency and low oil-consumption. 7. Little volume, light weight. 8. Steady operating, little vibration, low noise. 9. Simple & reliable constrution, easily disassembly & assembly,convenient maintainc 10. Reliable sealing without leakage. 11. Long operating life of parts  parameter selection

parameter selection

Shaft seal: Packing Seal :

Shaft seal: Packing Seal :

As one of the most commonly used seals for rotating shafts, the packing seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing. This kind of seal is suitable for use under all pumping conditions. In situations where corrosive solids or high temperature might be encountered, Teflon or aramid fiber is used as the packing material for the gland. For high abrasion conditions, a ceramic shaft sleeve is available. Expeller seal: The combination of impeller and expeller creates the pressure needed to seal against leakage. Together with the gland seal or lip seal which is used as the shut-down seal, this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site, or sealing water is allowed to enter inside the pumping chamber to dilute the slurry. Mechanical Seal :

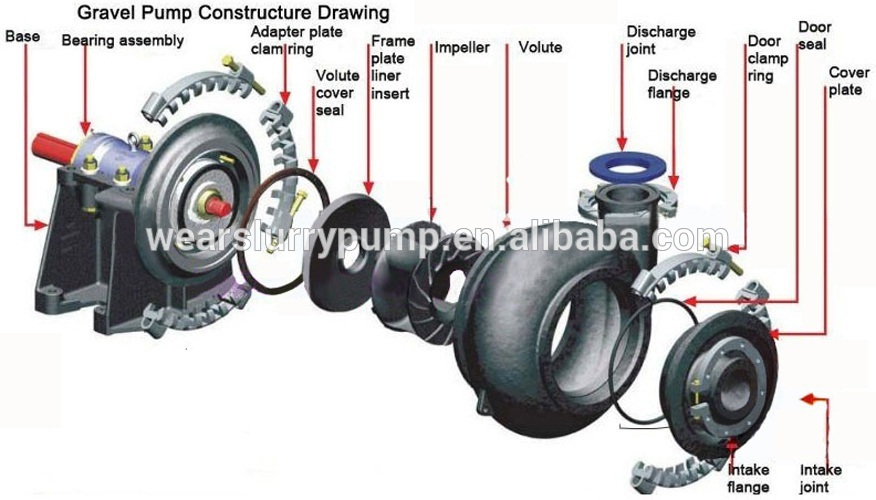

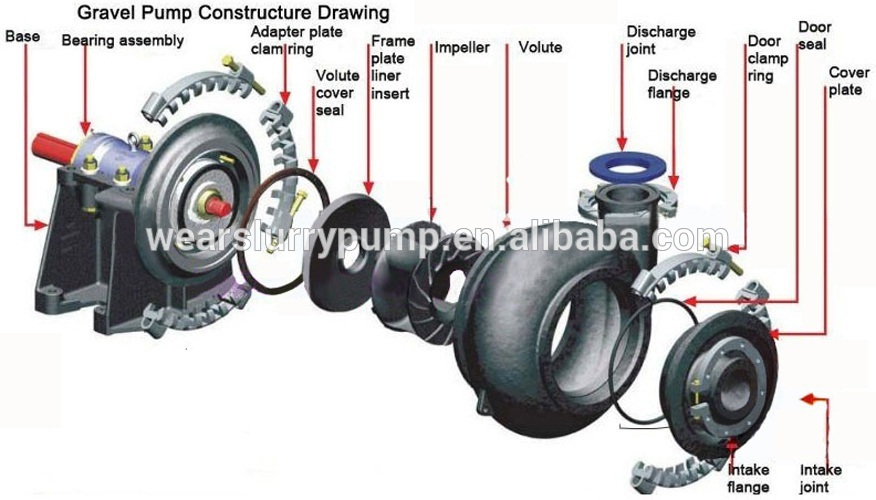

MH series heavy duty slurry pump utilizes a leak-proof mechanical seal design which allows easy installation and replacement. Other types of mechanical seal are among options to suit the slurry pump for various pumping applications. We also utilize special ceramic and alloys of high strength and hardness on parts that are subjected to friction. Unique design of and seamless fit between the mechanical seal and seal chamber provides excellent resistance to abrasion and shock that ensures its effectiveness under the toughest conditions. Component diagram:

Component diagram:  Pump Prossible faults and removal: Type MG pump has a compact construction. If it is correctly installed and operated, the pump will have a long life.

Pump Prossible faults and removal: Type MG pump has a compact construction. If it is correctly installed and operated, the pump will have a long life.

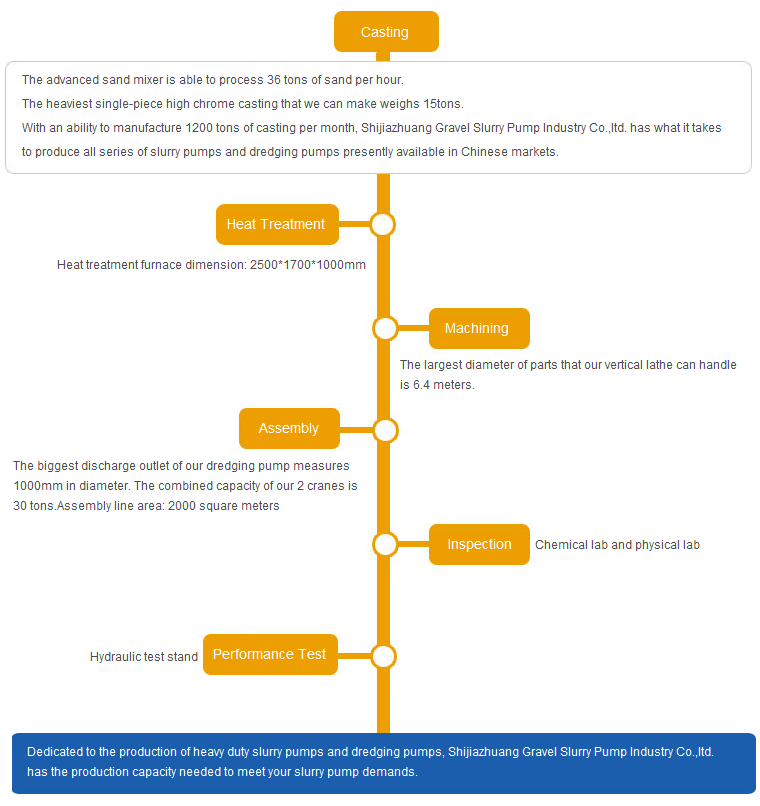

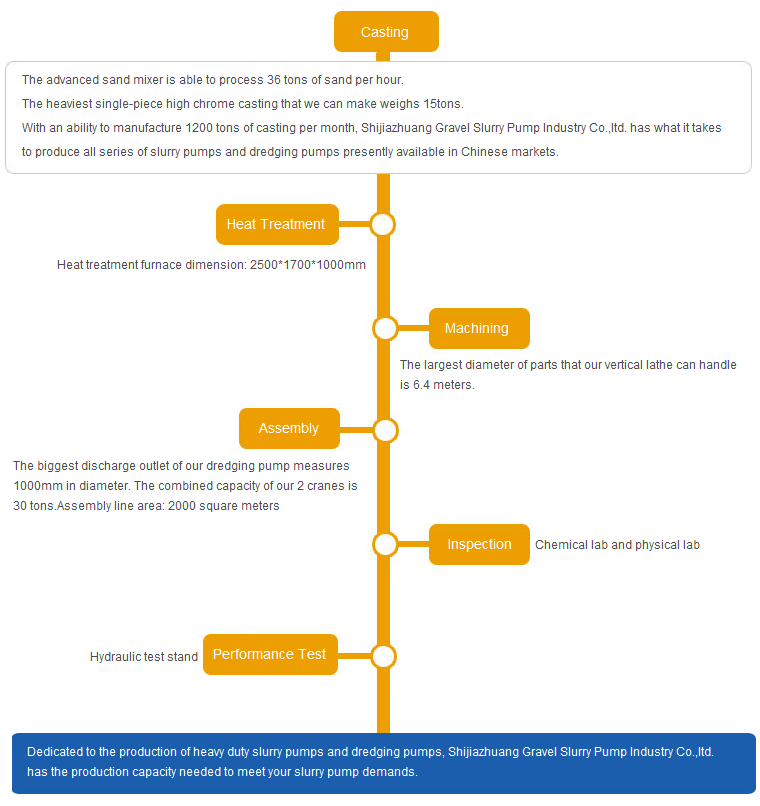

Shijiazhuang gravel slurry pump co.ltd Workshop: Shijiazhuang Gravel Slurry Pump Industry Co.,ltdhave firstclass production equipment.There are more than 100 sets of equipments,such as lost foam casting production line,shot last machine,heat treatment furnace,CNC lather,digital display large vertical lather,digital display horizontal milling machine,etc.  production process

production process  Onsite application:

Onsite application:  quality control

quality control

Packing &Shipping: As mostly we deliver by sea, so we package our pump and parts with plastic cloth inside and waterproof outside. The wooden cases are export standard, its thickness is 10mm at least.Also we have professional workers to do this cases.We are very near to Tianjin seaport, so it iscomfortable to deliver anytime, also the short delivery save the cost.

Packing &Shipping: As mostly we deliver by sea, so we package our pump and parts with plastic cloth inside and waterproof outside. The wooden cases are export standard, its thickness is 10mm at least.Also we have professional workers to do this cases.We are very near to Tianjin seaport, so it iscomfortable to deliver anytime, also the short delivery save the cost.

Our Services OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. FAQ: 1.Are you a manufacturer? Yes, we have been in manufacturing and marketing industry centrifugal pump over 10 years. 2.What information should I let you know if I want to get a quotation? Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please alsoprovide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference. 3.Q:Where is your factory located? How can I visit there? A:Our factory is located in Shijiazhuang City, Hebei Province, China.You can fly to Shijiazhuang airport directly.All our clients, from home or abroad, are warmly welcome to visit us! 4.Do you impact the finished product? Yes, each batch of production and finished product will be quality checked strictly before delivering Contact us

Our Services OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. FAQ: 1.Are you a manufacturer? Yes, we have been in manufacturing and marketing industry centrifugal pump over 10 years. 2.What information should I let you know if I want to get a quotation? Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please alsoprovide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference. 3.Q:Where is your factory located? How can I visit there? A:Our factory is located in Shijiazhuang City, Hebei Province, China.You can fly to Shijiazhuang airport directly.All our clients, from home or abroad, are warmly welcome to visit us! 4.Do you impact the finished product? Yes, each batch of production and finished product will be quality checked strictly before delivering Contact us

Advantage of our slurry pump: Competitive price; short lead time; powerful technical support for pump selection and problem solving Product Features MG detailed specification 1. Advanced hydraulic dredging pump model, CAD 3D design, high efficiency and obvious energy-saving 2. Large dredging sand depth, high density of dredging mud, good pump NPSH and strong suction lift ability. 3. Strong through-put. The dredging pump can persistently discharge gravel, high plastic soil lump,etc. 4.The dredging pump can be directly matched with either motor or diesel engine. 5. Wide application. The dredging pump can be used in various kinds of soil quality. Generally,the dredge pump is matched with an impeller with 3 or 5 pieces of vane. At the same time,the impellers can be provided with various diameters and vane types to suit kinds of working conditions. 6. Little hydraulic loss, high efficiency and low oil-consumption. 7. Little volume, light weight. 8. Steady operating, little vibration, low noise. 9. Simple & reliable constrution, easily disassembly & assembly,convenient maintainc 10. Reliable sealing without leakage. 11. Long operating life of parts

Advantage of our slurry pump: Competitive price; short lead time; powerful technical support for pump selection and problem solving Product Features MG detailed specification 1. Advanced hydraulic dredging pump model, CAD 3D design, high efficiency and obvious energy-saving 2. Large dredging sand depth, high density of dredging mud, good pump NPSH and strong suction lift ability. 3. Strong through-put. The dredging pump can persistently discharge gravel, high plastic soil lump,etc. 4.The dredging pump can be directly matched with either motor or diesel engine. 5. Wide application. The dredging pump can be used in various kinds of soil quality. Generally,the dredge pump is matched with an impeller with 3 or 5 pieces of vane. At the same time,the impellers can be provided with various diameters and vane types to suit kinds of working conditions. 6. Little hydraulic loss, high efficiency and low oil-consumption. 7. Little volume, light weight. 8. Steady operating, little vibration, low noise. 9. Simple & reliable constrution, easily disassembly & assembly,convenient maintainc 10. Reliable sealing without leakage. 11. Long operating life of parts  parameter selection

parameter selection

Shaft seal: Packing Seal :

Shaft seal: Packing Seal :As one of the most commonly used seals for rotating shafts, the packing seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing. This kind of seal is suitable for use under all pumping conditions. In situations where corrosive solids or high temperature might be encountered, Teflon or aramid fiber is used as the packing material for the gland. For high abrasion conditions, a ceramic shaft sleeve is available. Expeller seal: The combination of impeller and expeller creates the pressure needed to seal against leakage. Together with the gland seal or lip seal which is used as the shut-down seal, this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site, or sealing water is allowed to enter inside the pumping chamber to dilute the slurry. Mechanical Seal :

MH series heavy duty slurry pump utilizes a leak-proof mechanical seal design which allows easy installation and replacement. Other types of mechanical seal are among options to suit the slurry pump for various pumping applications. We also utilize special ceramic and alloys of high strength and hardness on parts that are subjected to friction. Unique design of and seamless fit between the mechanical seal and seal chamber provides excellent resistance to abrasion and shock that ensures its effectiveness under the toughest conditions.

Component diagram:

Component diagram:  Pump Prossible faults and removal: Type MG pump has a compact construction. If it is correctly installed and operated, the pump will have a long life.

Pump Prossible faults and removal: Type MG pump has a compact construction. If it is correctly installed and operated, the pump will have a long life. | Faults | Reason | Removal |

| Pump fails to discharge any liquid. | Incorrect direction of pump rota- tion and impeller worn. Suction pipe blocked | Check direction of rotation and replace a new impeller |

| Power consumption on sh- aft is excessive | Rotating component is rubbing on a stationary part. Bearing worn. Drive belt tension too tight Flow rate too large Pump speed and ratio too high. Misalignment or unparallel of ddrive shaft and pump shaft. | Removal the rub Replace the bearing Adjust belt Modify the pump duty and speed. Adjust drive and pump shaft |

| Bearing is over hearing | Lubricants too much or less. Containing impurities in the lubricant Bearing worn. | Lubricating as requirements. Replace clean lubricant. Replace new bearing. |

| Bearing has short life. | Misalignment or unparallel of drive and pump motor. Shaft bent. Impeller unbalanced due to wear Foreign object entered into the bearing or insufficient lubrication Incorrect procedure followed in fitting bearings. | Adjusting drive and pump shaft. Replacing shaft. Remove rubbing and replace new impeller Clean the bearing. Replace or refit the bearings. |

| Pump vibrates or is noisy. | Bearings worn. Impeller unbalanced. Air entered into suction pipe or blocked. Flow rate is none—uniform and pump not primed. | Replaced by new bearings. Replaced by new impeller. Discharge air and remove block. Improve on the pump feeding. |

production process

production process  Onsite application:

Onsite application:  quality control

quality control Stages of manufacture | Quality cotrol activities |

| Raw material arrival | Sampling, material chemical analysis |

| Casting and composition | Material material chemical analysis of pump parts |

| Casting quality inspection | |

| Key component machining | Dimension precision inspection |

| Impeller balancing | |

| General assembly | Procedure operaion |

| Hydraulic static test | |

Performance test of pump unit | Capacity and head |

| Vibration and noise | |

| Bearing temperature | |

| Final inspection | Packaging of pump unit |

| Documents | |

| Spare parts and accessories |

Packing &Shipping: As mostly we deliver by sea, so we package our pump and parts with plastic cloth inside and waterproof outside. The wooden cases are export standard, its thickness is 10mm at least.Also we have professional workers to do this cases.We are very near to Tianjin seaport, so it iscomfortable to deliver anytime, also the short delivery save the cost.

Packing &Shipping: As mostly we deliver by sea, so we package our pump and parts with plastic cloth inside and waterproof outside. The wooden cases are export standard, its thickness is 10mm at least.Also we have professional workers to do this cases.We are very near to Tianjin seaport, so it iscomfortable to deliver anytime, also the short delivery save the cost.

Our Services OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. FAQ: 1.Are you a manufacturer? Yes, we have been in manufacturing and marketing industry centrifugal pump over 10 years. 2.What information should I let you know if I want to get a quotation? Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please alsoprovide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference. 3.Q:Where is your factory located? How can I visit there? A:Our factory is located in Shijiazhuang City, Hebei Province, China.You can fly to Shijiazhuang airport directly.All our clients, from home or abroad, are warmly welcome to visit us! 4.Do you impact the finished product? Yes, each batch of production and finished product will be quality checked strictly before delivering Contact us

Our Services OEM service: Produce the pump and spare parts according to client's drawing or sample. Pump slection: Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. Using service :Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. Quality control :Pay more attention to the quality in every process with different instruments. Material service :Interchangeable metal design allow best material choice for any application. After-sales service: Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. Guarantee :One year guarantee for whole machine except of the wet end parts. FAQ: 1.Are you a manufacturer? Yes, we have been in manufacturing and marketing industry centrifugal pump over 10 years. 2.What information should I let you know if I want to get a quotation? Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please alsoprovide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference. 3.Q:Where is your factory located? How can I visit there? A:Our factory is located in Shijiazhuang City, Hebei Province, China.You can fly to Shijiazhuang airport directly.All our clients, from home or abroad, are warmly welcome to visit us! 4.Do you impact the finished product? Yes, each batch of production and finished product will be quality checked strictly before delivering Contact us

Related Keywords

Related Keywords

You May Also Like

You May Also Like