Color Coated Galvanized Steel Coil Width 1250mm

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA, CPT, CIP

- Min. Order:

- 25 Ton

- Min. Order:

- 25 Ton

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shandong province |

|---|---|

| Productivity: | 18000tons per month |

| Supply Ability: | 180000 ton per year |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA,CPT,CIP |

| Certificate: | ISO9001 & BV |

| Transportation: | Ocean,Land,Air |

RAL Color Coated Galvanized Steel Coil

We are a professional manufacturer and exporter of Steel Roll Forming Machine, and corrugated steel sheet, sandwich panel and steel coils in shangdong.

Our workshop covers more than 10,000 square meters and about 150 technical staffs work in our factory. We have rich technical force,high-level managerial team, advanced production facilities, strong production capacity and strict quality control system.

What we value is reputation and service, what we sell is quality and technology.

If you have interesting please do not hesitate to contact me.

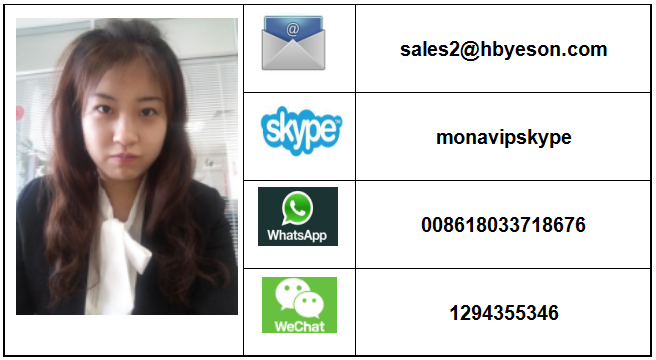

Manager: MONA

TEL: 86-311-67695456

MOB: 86-18033718676

FAX: 86-311-67695455

Skype: monavipskype

Product Description

Product DescriptionCoil Feature:

1. Galvanized base with color painted coils take hot-dip galvanized steel coil as its basic material. Factory adopts the newest technologies and the most advanced equipments to degrease, rinse, chemical transform the cold-rolled steel coils or galvanized steel coils. Then we make primary and refined lavation for the steel strips.

2. We use worldwide advanced solidify furnace to solidify the coasting surface. This kind of color painted coils has excellent capability of decoration, molding, corrosion resistance ability. It keeps the products with color coatings in flamboyant color for a long time.

3. Nowadays, it has become the most perfect building materials in construction, transportation, manufacture, light industry, office furniture, household electric appliances, food package, and other areas all over the world.

Technical specification of galvanized steel coil :

Standard Steel grades Application GB/T 2518-2004 01 Common commercial application 02 For mechanical engagement 03 For stamping 04 For deep drawing 220,250,280,320,350 For structural components JIS G 3302-1998 SGCC Common application SGCC1 For stamping SGCC2 For deep drawing DIN EN 10142-2000 DX51D+Z For common application and mechanical engagement DX52D+Z For stamping DX53D+Z For deep drawing DIN EN 10147-2000 S220GD+Z For structural components S250GD+Z S280GD+Z S320GD+Z S350GD+Z

Product Pictures:

Our Advantages:

Our machine Other company 's machine Influence of the machine Machine's base High strength H350 / H400 steel. machine through milling macine after welding H270 steel mark, after welding use manual polish keep base in the same horizontal line, ensure product standard

Roller material High grade No.45 forged steel, with digital-controlled procession, Plated with 5 um chrome coated Normal No. 20 steel with Simple polished and have no coating Roller will have longer use life and ensure the products have same size,no nick on the surface.

Side wall Use high strength16mm thickness steel panel mark Use 12 mm thickness steel panel mark Ensure machine harder to deform, keep the product accurate and stable

Active shaft material High grade solid No.45 carbon steel, Shaft diameter is 72mm. surface CNC polish treatmen Normal No. 45 steel with no surface treatment Improve the integrated mechanic feature of the shaft. and ensure the shaft stability keep product standard

Electrical elements PLC control panel, transducer imported from Mitsubishi of Japan. Other elements from famous suppliers in China All the elements are made in china Machine become more accurate and more stable

Cutter blade Cr12 mould steel with quenched treatment Normal high strength steel without quenched treatment Stable the integrated mechanic feature of the cutter blade,harder to deform, longer blade's life, ensure product standard

Design Ability:

- We have more than 20 years experience in produce roll forming machine,

- We have a group of professional engineers,

- We have a lot of customer's feedback data,

- We can design the machine and product according to your request.

Related Keywords