Square Round tube Pipe Mill forming Machine

-

$40000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express, by train

- Port:

- TIANJIN, XIAMEN, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 500 SETS |

| Supply Ability: | 500 SETS |

| Payment Type: | L/C,T/T,D/P,Paypal,D/A |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP,DEQ,Express Delivery,DAF,DDU,DDP,FAS,DES |

| Certificate: | ISO 9001 / CE |

| HS Code: | 84552210 |

| Transportation: | Ocean,Land,Air,Express,by train |

| Port: | TIANJIN,XIAMEN,Shanghai |

1.Product Description

2. Product Specification / Model

Welded Pipe Roll Forming Machine Roll Forming Machine Forming Machine

pipe roll forming machine stainless steel pipe making machine Tube Square Pipe Mill Making Machine

Product Description

The machine includes passive uncoiler unit,sheet guiding equipment,roll forming system,post cutting equipment,hydraulic station,PLC system and run out table and the bending machine

Product Feature

The machine includes passive uncoiler unit,sheet guiding equipment,roll forming system,post cutting equipment,hydraulic station,PLC system and run out table and the bending machine

Product Specification / Models

highfull

Application / Models

highfull

Other Information

Welded Pipe Roll Forming Machine roll forming machine forming machine

1:Introduction

The machine includes passive uncoiler unit,sheet guiding equipment,roll forming system,post cutting equipment,hydraulic station,PLC system and run out table and the bending machine

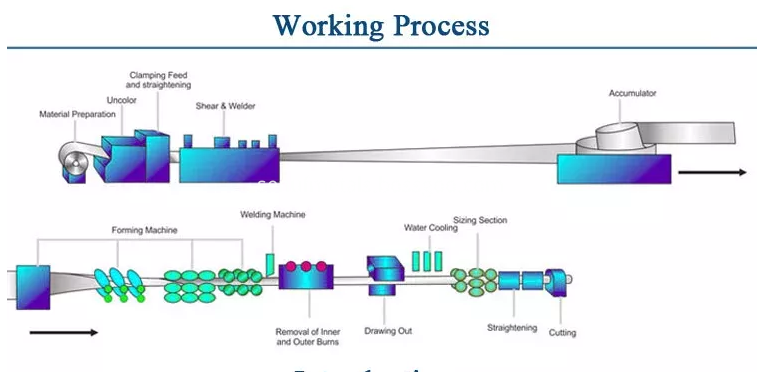

2: Working Flow

Decoiling the sheet---Sheet guiding----Roll forming ----Measure length----Cutting the panel----panels to the supporter

3:Technical Parameters

Material spec: Galvanized sheet and color sheet

Thickness: 0.60mm-2.0mm

Coil stress: 235Mpa

Roll forming speed: 5-15 m/min

Simple uncoiler max capacity:3000kgs

Main motor power: 4kw

Hydraulic station power: 5.5kw

Quantity of stands: about 20 groups

Voltage as the client request

uncoiler

Usage:It is used to support the steel coil and uncoil it in a turnable way.

Passive uncoil pulled by roll forming system

Loading capacity 5T

Uncoiling width 450mm(according to the profile)

Inner diameter: 450-550mm

feeding and punching

Usage:Put the raw material(steel plate) through the beach to manufacture and process,4 down and 3 up , it can guarantee

that the products are neat, parallel and everything is uniformity.

Material of axis 45#steel

Number 3 up,4 down

Diameter of axis 100mm

Forming round Material bearing steel (GR15), quenching 60-62 °C

forming machine

4: Material of Main Equipment

Roller Material:High grade No.45 forged steel, with chrome coated

Active Shaft Material:High grade No.45 carbon wrought steel

Electric Elements PLC control panel with touch screen transducer imported from

Mitsubishi of Japan.Other elements from famous suppliers in China

Cutter blade Cr12 mould steel with quenched treatment

5: Standard Equipment of Machine

Passive Uncoiler 3ton with inner diameter 508mm 1set

Roll Forming Equipment 1set

Post Cut Equipment 1set

Hydraulic Station 1set

PLC Control Penal 1set

Supporter Table 2M 2sets

6.Terms:

1. Delivery: According to customers' requirement

2. Package: Export standard package for container

3. Payment: TT (30% by TT in advance, 70% by TT after you inspect machine we need)

4. Delivery date: Within 30 working days after receiving deposit

5. Products Warranty: 12 month, and we will provide the technical support for whole life of the equipment.

Related Keywords