Neoprene/CR Oil Resistance Rubber O Ring

- Payment Type:

- L/C, T/T, Paypal, Western Union, WeChat

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 300 Piece/Pieces

- Min. Order:

- 300 Piece/Pieces

- Delivery Time:

- 5 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin, Qingdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 pcs/day |

| Supply Ability: | 10000 pcs/day |

| Payment Type: | L/C,T/T,Paypal,Western Union,WeChat |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO 9001/ISO/TS 16949 |

| HS Code: | 4016931000 |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,Qingdao,Shanghai |

Neoprene/CR Oil Resistance Rubber O Ring

Good elasticity fireproof rubber o ring seals could be made by Neoprene/CR.

Vulcanized rubber elastic wear resistance, not afraid of the direct sunlight, there is a particularly good resistance to atmospheric aging performance, not afraid of intense distortion, not afraid of dichlorodifluoromethane and ammonia and other refrigerants, resistant to acid, resistant to silicon Lubricant, but not resistant to phosphoric acid ester hydraulic oil. It is easy to crystallize at low temperature, harden, and has poor storage stability, and is large in mineral oil with low aniline point. The general use of the temperature range of -50 ~ 150 ℃

· Suitable for all kinds of fire-resistant, chemical-resistant rubber products.

We, Beike Sealing, main produce rubber Rubber gaskets and o ring seals. JIS Standard, ISO Standard or Non standard o ring seals, with different rubber materials.

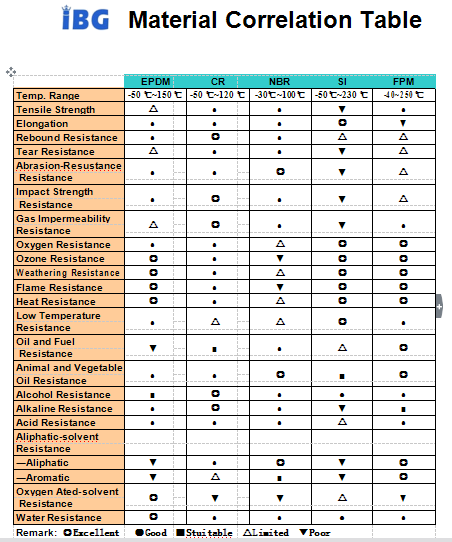

Many rubber material for you choose

How to select the right material

*Drawings, photos and samples are welcomed.

· Good elasticity and good compression deformation.

The formula does not contain sulfur so it is very easy to produce

· With anti-animal and vegetable oil characteristics

· It does not affect physical properties due to neutral chemicals, esters, oils, various oils and solvents

· Fire resistance rubber o ring

Disadvantages:

• It is not recommended to use strong acids, nitrohydrocarbons, esters, chloroform and ketones. Resistance to R12 refrigerant seals. • Rubber parts or seals on household appliances.

· Suitable for making all kinds of direct contact with the atmosphere, sunlight, ozone parts.

Butyl Excellent resistance to ketones, paint, ink dryers and ozones.

EPDM Excellent resistance to heat aging, ozone, acids, and alkalines.

Fluroelastomer (Viton) Excellent resistance to oils, fuels and solvents at higher temperature ranges.

Neoprene General industrial material used with non-aromatic petroleum oils and greases.

Nitrile ( Buna-N) (NBR) General industrial use material for oil, grease and solvent resistance.

Polyurethane (PU) Rubber like material with toughness and durability beyond the range of most rubber or plastics.

Silicone Excellent material for resistance to aging, heat, sunlight, many oils, and chemicals.

It's important to select the right rubber material for the applicaiton and the environment. Most rubber materials will have the flexibility to be used in rubber bellows applications - Beike Sealing. can work with you to identify the best, most cost effective material for your application.

1.What medium will contact when using, oil, chemicals...?

2.What is application temperature?

3.Dynamic seal or static seal?

4.Surface seal or shaft seal?

*We can produce the product according to your requirement or samples.

*Any questions or need more information, please feel free to contact with us.

*We are looking forward to have a good cooperation with you.

*welcome to visit our factory

1). Products in stock, delivery time is 1 workday;

2). Products out of stock, and mold in stock, delivery time is 5~7 workdays;

3). Products out of stock, and mold out of stock, delivery time is 10~15 workdays.

Remark: Delivery time is also subject to quantity.

Related Keywords