Maize posho mill machine prices

Your message must be between 20 to 2000 characters

Contact NowMaize posho mill prices in kenya

Technical parameter

| Capacity | 10 Tons/day |

| Power | 43 kw |

| Workshop size(L*W*H) |

16.5x7x4.5m |

| Weight | 4T |

| Voltage | 380 v |

| Container | 20 GP*1 |

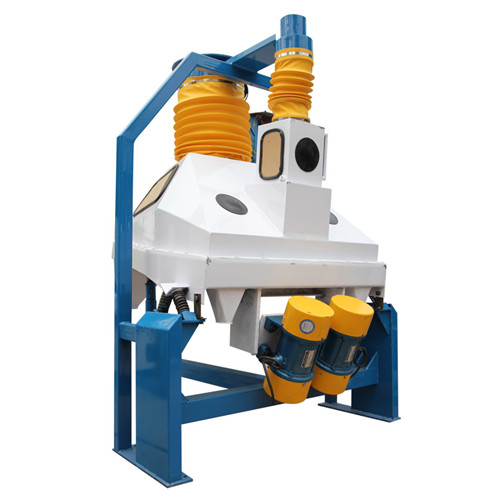

Goldrain Maize Flour Mill mainly has two parts, cleaning part consists of cleaner, destoning,dampening, degerminator and the milling parts mainly use roller mills and double sifters.This series maize Flour Mill is usually designed in steel structure. Our maize flour mill have scientific design and configuration, elegant appearance, high efficiency, low power consumption, low production costs, with low noise and zero pollution.

1. Production capacity: 30tons corn/24h

2. Production variety:

1) Maize fine flour; 2) Maize big rice; 3) Maize small rice; 4) Maize germ; 5) Maize bran; 6) Fodder flour

3. Production extraction:

1) Maize rice: 35-45%

2) Maize fine flour: 30-40%

3) Maize germ: 6-10%

4) Maize bran and Fodder flour: 14-10%

Maize mill machine processing line:

1. Cleaning section

In most cases, the raw materials delivered to the mills are not pure grains. Prior to their processing, foreign materials and other contaminants introduced during the harvest, transport and storage of the grain must be removed. The removal of such impurities guarantees the quality of the end products, by reducing ash content, specks, and factors influencing odor and flavor. Additionally, machine wear is reduced and their lifespan increased.

2. Milling Sifting section:

Grinding the corn into flour, grits, meal different micron according to customers' requirement.

Also we adopt the sifter to classification and grading the flour.

3. Weight Packing section :

We adopt 10-25 kg / bag or 25-50 kg / bag for final product packages .

Related Keywords