Aluminum Die Casting Door Handle Parts

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA, CPT

- Min. Order:

- 100 Bag/Bags

- Min. Order:

- 100 Bag/Bags

- Delivery Time:

- 35 Days

- Transportation:

- Ocean, Air

- Port:

- TianJin, Xin'gang

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Certificate: | ISO 9001:2008 |

| Transportation: | Ocean,Air |

| Port: | TianJin,Xin'gang |

Aluminum Die Casting Door Handle Parts

YD CASTINGS was established in 2006,is a professional Aluminum alloy die casting ,Iron Casting and CNC machining Manufacturer. We have more than 10 years experience in casting industry. Our facilities include Aluminum die castings, Aluminum Die Casting Door Handle Parts and Aluminum Furniture Accessories machined from 180~800 ton. In addition,we have advantage at surface treatment. Especially in plating,coating and anodizing. Our products have been exported to Europe, North Ameican, Asia, etc. Strong technical force ,high quality standard and reasonable price is our target.

Casting Material: Aluminum ADC12, A380, 101A or according to your request

Processing: Die Casting; Drilling; Tapping; Milling; Turning; Threading; Polishing& Grinding; CNC machining; Deburring; Quality check; Package; Delivery.

Surface Treatment: Polishing, Spray Coating, Powder coating, Anodizing

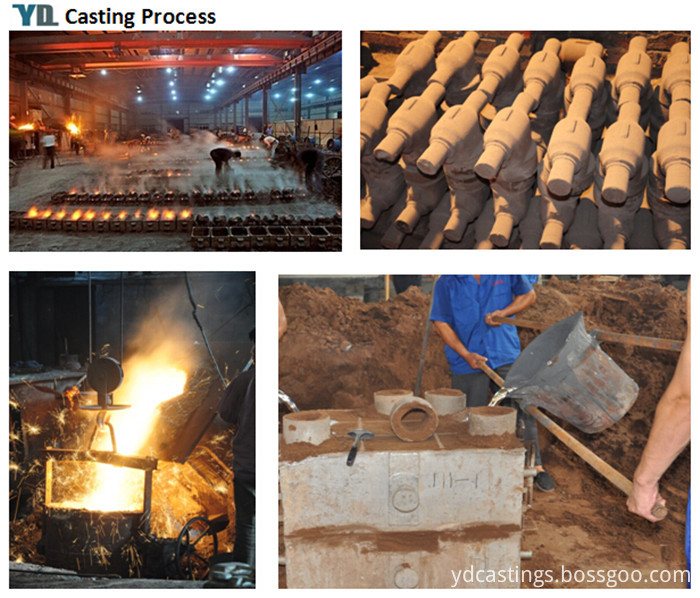

Production Flow Chart:

Drawing Analysis→ 3D Making→ Mould Making →Die casting and other processes →Machining →Get Samples and Send Samples to Customer for confirm → Mass Production (Casual inspection avoid unintentional situation) → IPQC→FQC→OQC →Packing→ Shipping →Cycle to next order

Drawings for quotation: PDF, AUTO CAD, Solidworks, Proe, ect.

Our Advantage:

1) - ISO Certified Die Casting Parts manufacturer with more than 10 years OEM experience.

2) - Quality Engineers and Inspectors with more than 20years working experience

3) - Highly skilled manufacturing process

4) -100% inspection(offer QC reports)

5) - Just In Time Delivery and low cost ensured by our own tooling-making workshop and aluminum smelting workshop

6) -Strict Quality Control System

Our aluminum alloy products also include Aluminum Casting Auto Parts, Aluminum Casting Electric Motor Parts, Aluminum Casting Lighting Fixture, Aluminium Casting Furniture Parts, Aluminum Casting Camera Parts and Aluminum Telecommunication Parts.

Related Keywords