Aluminium Die Casting Auto Engine Covers

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA, CPT

- Min. Order:

- 200 Piece/Pieces

- Min. Order:

- 200 Piece/Pieces

- Delivery Time:

- 40 Days

- Transportation:

- Ocean, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Certificate: | ISO 9001:2008 |

| Transportation: | Ocean,Air |

Aluminium Die Casting Auto Engine Covers

Hebei Yuanda Trade Co., Ltd. can provide Aluminium Die Casting Auto Engine Covers, Die Casting Engine Parts, Aluminum Motorcyle Part Engine Covers and other Die Casting Aluminum Auto Parts. Die casting is the process where molten metal is injected into a mold under high pressure. This will result in a highly uniform casting with very good surface finish and exceptional dimensional accuracy. We can offer both the cold chamber process and the hot chamber process. In the cold chamber process the metal is ladled into the injection chamber for each shot. There is less exposure of the molten metal to the chamber walls and plunger. This is very useful for aluminum alloys that would easily alloy with iron at elevated temperatures. The hot chamber process has the injection chamber which is connected to the die cavity permanently immersed in the molten metal. The hot chamber process is used for metals of low melting point and high fluidity such as tin and zinc. We can also provide many other kinds of aluminum alloy casting products, including Aluminum Casting Electric Motor Parts, Aluminum Casting Lighting Fixture, Aluminium Casting Furniture Parts, Aluminum Casting Camera Parts and Aluminum Telecommunication Parts.

1) Surface Treatment

Shot blasting, Sand blasting, Painting, Polishing, Anodize, Chrome plating, Power coating, E-coating, etc.

2) Machining Equipments

Lathe, Wire EDM, Laser cutting, NC stamping press machine, CNC milling, turning and grinding machine, Stamping Press, CNC, Bending machine, Drilling machine, Milling machine, Boring machine, Grinding machine, Turning machine and Machining Center etc.

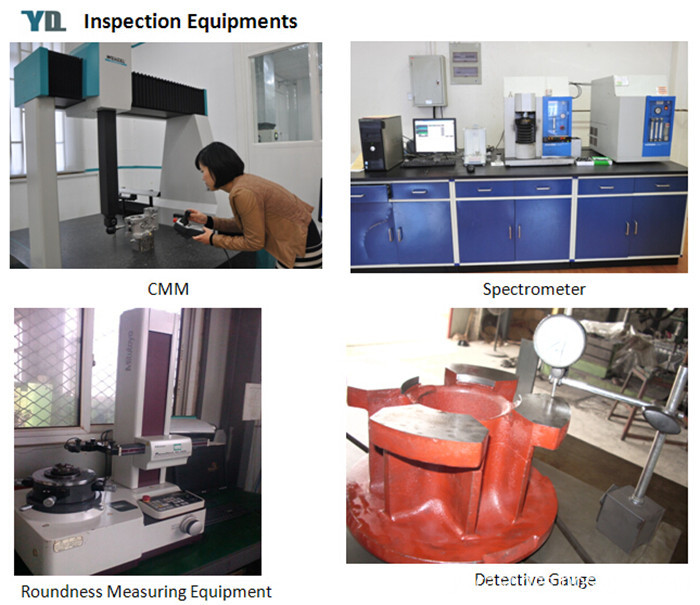

3) Inspection Equipments:Direct-reading spectrograph,metallographic microscope,hardness tester,brinell hardness tester,thermometric indicator,universal testing machine,carbon and silicon analysis meter,magnetic powder flaw detector,digital ultrasonic flaw detector etc.

Our Service:

1.Your inquiry related to our products or prices will be replied soon.

2.Individual formula according to customers' special drawing requests.

3.Manufacturer with large capacity,ensures the fast production cycle after

confirming the order.

4.Protection of sales area and private information for all of our customers.

Related Keywords