OEM Aluminum Security Camera Brackets

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA, CPT, CIP

- Min. Order:

- 50 Piece/Pieces

- Min. Order:

- 50 Piece/Pieces

- Delivery Time:

- 45 Days

- Transportation:

- Ocean, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA,CPT,CIP |

| Certificate: | ISO9001:2008 |

| Transportation: | Ocean,Air |

Material:

Aluminum ingot ADC12

Application:

CCTV Camera Housing

Processing:

Pattern-molding-die casting-machining-cleaning-finishing

Die Casting Machine:

160 to 1250 tons cold chamber

Tolerance:

+/-0.05mm or as you request

Single Part Weight:

Can cast from 0.02kg to 10kg per piece

Machining:

CNC, Turning-lathe, NC-Boring machine, NC-Drilling machine.NC-Milling machine

Surface Treatment:

Sand blasting, anodizing, powder spraying, polishing, electroplating, paint coating, per your requirements.

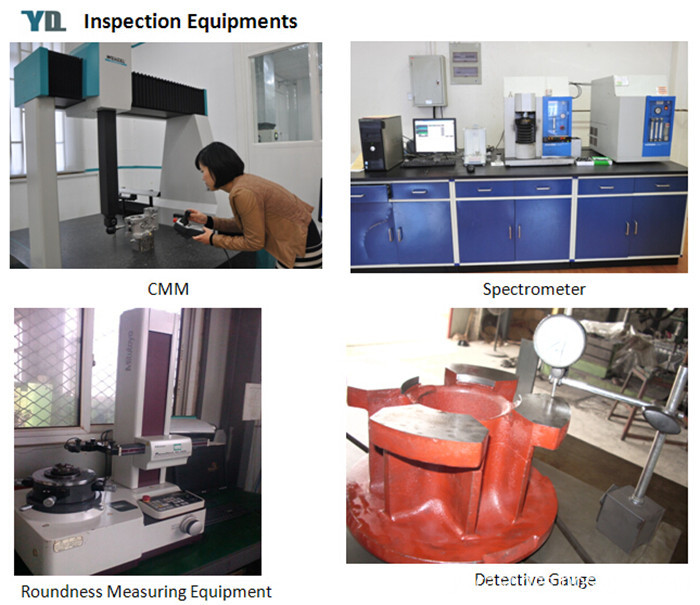

Inspection Equipments:

CMM, spectrum analysis instrument, metallurgical analysis, tensile strength tester, hardness tester, roughness tester, deflection tester, impact test machine, pressure tester etc.

Quality Control:

1. Drawing control

1) Confidentiality–Be confidential to the customers` drawings.

2) Check- Technician checks the drawings and confirms dimensions

3) Confirmation – Confirm the production process & inspection process according to the drawings

2. Mold making control

1) Inspect the dimensions and material according to drawing.

2) Send test reports and photos to customers.

3. Raw Casting control

1 Produce according to the production tracking form

2) Use advanced inspection equipments to ensure internal quality of the product.

3) Check the test bar and record relevant information to each bulk.

4) Send the photos and test data of each step to customers.

4. Machining process control

1) Produce the samples according to the confirmed casting process.

2) Train the relevant staff before producing according to the machining and inspection process.

3) Our inspector will track the quality and time of the products during producing. Any problems on quality and process must be feedback to our customers.

4) Do the finial inspections to the products and send the relevant data and finished product photos to the customers.

5. Packing and Delivery control

1) Determine the size & material of the box according to the shape & number of products.

2) Taking different anti-rust protection to products according the delivery time

3) Put dimensional reports, chemical & mechanical documents, test bar and photos into the packing box

4) Send the photos of whole packing process to customers.

Related Keywords