ISO9001 Certificate Aluminum Casting Parts

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA, CPT

- Min. Order:

- 50 Piece/Pieces

- Min. Order:

- 50 Piece/Pieces

- Delivery Time:

- 40 Days

- Transportation:

- Ocean, Air

- Port:

- TianJin, Xin'Gang Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Certificate: | ISO9001:2008 |

| Transportation: | Ocean,Air |

| Port: | TianJin,Xin'Gang Port |

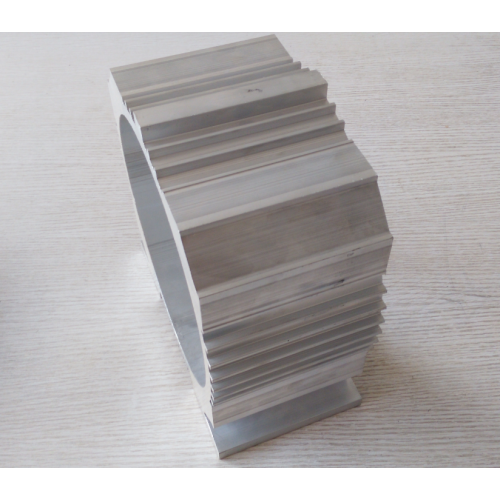

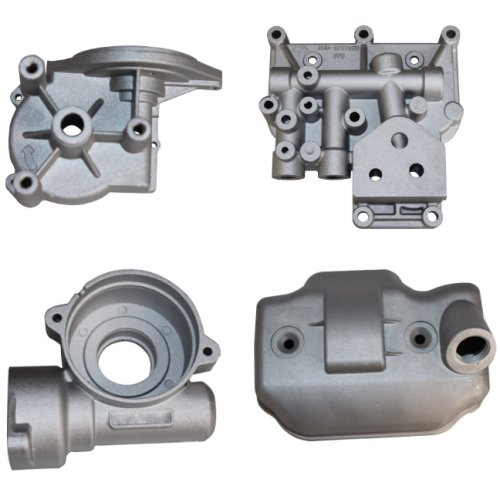

ISO9001 Certificate Aluminum Casting Parts

HeBei Yuanda Casting Co., Ltd. was established in 2006. We have a full range of import and export rights and we are a professional manufacturer of Aluminum Casting Parts, Aluminum Alloy Casting Parts and Die Castings with ISO Certificate. We are committed to providing the highest quality products to customers. We have a wide range of machining capabilities, include manual and CNC, whcih allow us to do small quantity work as well as high quantity production orders. All jobs, large or small, are geared toward achieving the same goal: providing complete and quality service you can count on. Based on good quality products with reasonable price, we exported our products to Europe, the USA, etc. Machining service as per your requests and specification drawings, either small or large quantity is acceptable for us. We are sincerely expecting to cooperate with you.

Material:

Alloy of AL-Si-Cu, Al-Si-Mg series(A360,A380,A356,ADC12,etc)

Casting Process:

Die casting, sand casting and permanent mold casting

Machining:

CNC, Turning-lathe, NC-Boring machine, NC-Drilling machine.NC-Milling machine

Surface Treatment:

Sand blasting, anodizing, powder spraying, polishing, electroplating

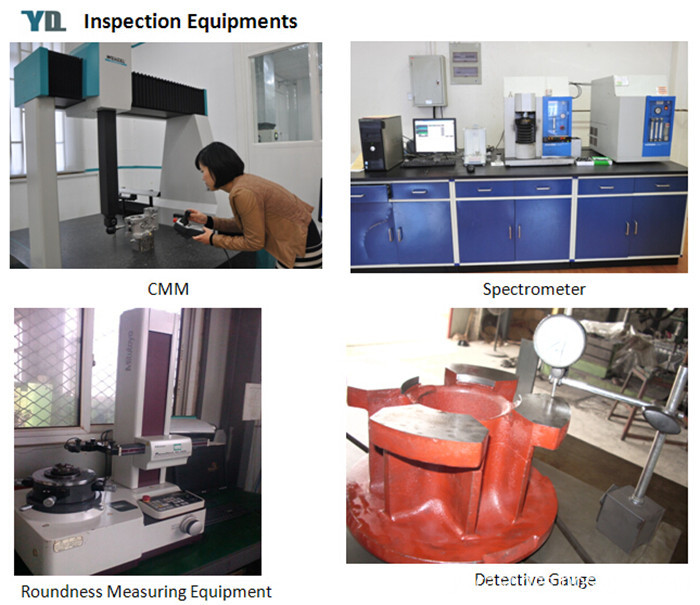

Inspection Equipments:

CMM, spectrum analysis instrument, metallurgical analysis, tensile strength tester, hardness tester, roughness tester, deflection tester, impact test machine, pressure tester etc.

Quality Control:

1.

Drawing control

1) Confidentiality–Be confidential to the customers` drawings.

2) Check- Technician checks the drawings and confirms dimensions

3) Confirmation – Confirm the production process & inspection process

according to the drawings

2. Mold making control

1) Inspect the dimensions and material according to drawing.

2) Send test reports and photos to customers.

3. Raw Casting control

1) Produce according to the production tracking form

2) Use advanced inspection equipments to ensure internal quality of the

product.

3) Check the test bar and record relevant information to each bulk.

4) Send the photos and test data of each step to customers.

4. Machining process control

1) Produce the samples according to the confirmed casting process.

2) Train the relevant staff before producing according to the machining and

inspection process.

3) Our inspector will track the quality and time of the products during

producing. Any problems on quality and process must be feedback to our

customers.

4) Do the finial inspections to the products and send the relevant data and

finished product photos to the customers.

5. Packing and Delivery control

1) Determine the size & material of the box according to the shape &

number of products.

2) Taking different anti-rust protection to products according the delivery

time

3) Put dimensional reports, chemical & mechanical documents, test bar and

photos into the packing box

4) Send the photos of whole packing process to customers.

Our aluminum alloy products also include Aluminum Casting Electric Motor Parts, Aluminum Casting Auto Parts, Aluminum Casting Lighting Fixture, Aluminium Casting Furniture Parts and Aluminum Casting Camera Parts.

Related Keywords