Lap join stub ends

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 18 Days

- Transportation:

- Ocean, Land, Air, Train/TNT/DHL

- Port:

- Beijing Air Port, Tianjin New Port, Zhengzhou Train Station

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Cangzhou,China |

|---|---|

| Productivity: | 1000pcs/month |

| Supply Ability: | 1000pcs/month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO/CE/API |

| HS Code: | 73072100 |

| Transportation: | Ocean,Land,Air,Train/TNT/DHL |

| Port: | Beijing Air Port,Tianjin New Port,Zhengzhou Train Station |

Stub end

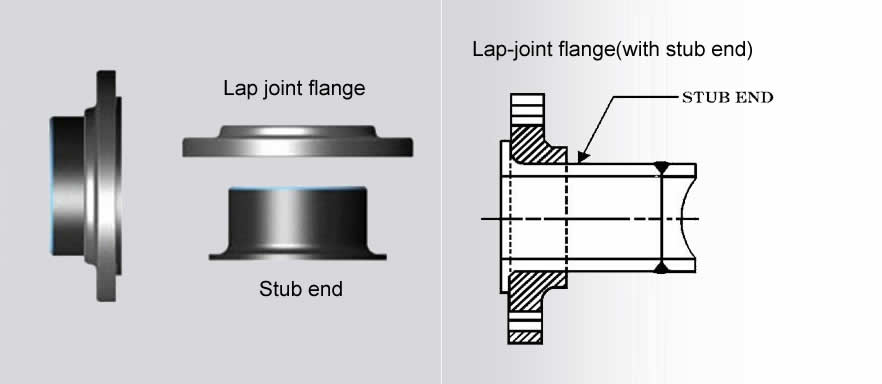

Stub ends are mechanical joints that comprises of two components.

The Stub End is available with us in different specifications, which find applications in a piping system to allow quick disconnection of the particular section involved.

Stub End is the fitting that be used in place of welded flanges where rotating back up flanges are desired.

They are also called Lap Joints and Vanstone Flared Laps.

Stainless stub end

Stainless Steel Stub End such as Stainless Steel Stub Ends ASTM A403, Stainless Steel Stub End 304L, Stainless Steel Stub End 316L, Stainless Steel Stub End 317

Carbon steel Stub end

Our high quality stub ends (Butt Weld Pipe Fitting ) are tested and verified for durability, accuracy and precision.

Lap joint stub end

The Lap joint stub end is the fittings that are used in place of welded flanges when the support of rotating back up flanges is required.

Lap Joint Flange

Lap Joint Flange Stub End - available in a range of sizes to pair with stub end fittings for easy dismantling

There are three different types of stub ends, Type A, B and C. Type A stub ends are machined to fit in a standard lap joint backing flange

We offer stub ends at highly competitive prices.

Lap Joint Stub End – The `mated` pair to a Lap Joint Flange. Stub Ends are Fittings used in place of welded flanges where rotating back up flanges are desired. Stub Ends are typically manufactured by two methods, Type A & Type B and are available in two standard lengths , long (ANSI) or short (MSS) pattern.

Features:

- Thermal stability

- High mechanical strength

- Long functional life

Manufacturing standards of stub end:

- ASTM ASME A/SA 403

- MSS SP43 &Mss Sp-75 Asme B16. 9

- ANSI B16. 28 ASTM A815 ASTM B363 B366

- DIN2605 DIN2615 DIN2616 DIN2617

- GB12459GB13401

- JIS2313

Specifications:

- Grades: ASME / ASTM SA / A234

- Material:

- Stainless Steel,316/316L Stainless Steel, 304/304L Stainless Steel and Chrome-moly

- Carbon steel

Technical Specifications:

- Thicknesses are based on ASME B16.48 specifications or the products can be manufactured to customer specifications.

- Standard surface finish is 125-250 RMS serrated finish.

- Other finishes available upon request.

- c/w a standard shop primer on carbon steel products for rust inhibitor purposes.

- Size: Available in all sizes and thickness

Usage:

Petroleum, Chemical, Power, Gas, Metallurgy, Ship-building, Construction, ect.

Using stub ends allows sections of the line to be opened for cleaning, inspection, or quick replacement etc, without the need to re-weld.

Specifications:- Grades: ASME / ASTM SA / A234

- Material: Stainless Steel

- Size: Available in all sizes and thickness

-

Related Keywords