Alloy Steel Forged Sockolet

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air, Train/TNT/DHL

- Port:

- Tianjin New Port, Beijing Air Port, Zhengzhou Train Station

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Cangzhou,China |

|---|---|

| Productivity: | 1000pcs/month |

| Supply Ability: | 1000pcs/month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO/CE/API |

| HS Code: | 73079300 |

| Transportation: | Ocean,Land,Air,Train/TNT/DHL |

| Port: | Tianjin New Port,Beijing Air Port,Zhengzhou Train Station |

Alloy Steel Forged Sockolet

Standard size of Thread Pipe Fitting ,professional supplier of Weld Threaded Socket Fittings ,good choice of Thread Steel Fitting

SOCKOLET

Our forged steel outlet fittings Sockolets (3000) is developed using different grade and material. The ideal run pipe sizes for sockolets 3000 is out let to 36". The inside bore, thread, socket bore and socket depth of sockolets 3000 is designed as per ANSI B16.11 but the pipe schedule numbers & weight designation is as per ANSI B36.10. We provide customization on our range as per the specification of clients.

Specifications

Outlet`s : 1/2" to 24" in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75.

Stainless Steel Sockolet

Standard : ASTM / ASME A/SA 182

Grade : F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L.

Carbon Steel Sockolet

Standard : ASTM A105/A694/ A350 LF3/A350 LF2.

Grade : F42/46/52/56/60/65/70

Alloy Steel Sockolet

Standard : ASTM A182

Grade : F1/F5/F9/F11/F22/F91

Dimensions

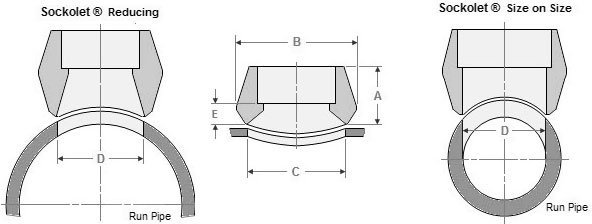

Dimensions reducing and size on size Sockolets® acc to MSS-SP97

REDUCING SIZES |

||||||

| NPS | Pressure Class 3000 - NPS 1/2 up to NPS 6 | |||||

| A | B | C | D | E | ||

|

1/2

|

INCH

MM |

1

25.40 |

1-13/32

35.71 |

29/32

23.01 |

0.622

15.80 |

9/16

14.28 |

|

3/4

|

INCH

MM |

1-1/16

26.98 |

1-23/32

43.65 |

1-5/32

29.36 |

0.824

20.93 |

9/16

14.28 |

|

1

|

INCH

MM |

1-5/16

33.33 |

2

50.8 |

1-7/16

36.51 |

1.049

26.64 |

25/32

19.84 |

|

1 ¼

|

INCH

MM |

1-5/16

33.33 |

2-9/16

65.08 |

1-3/4

44.45 |

1.380

35.05 |

3/4

19.05 |

|

1 ½

|

INCH

MM |

1-3/8

34.92 |

2-27/32

72.23 |

2

50.8 |

1.610

40.89 |

3/4

19.05 |

|

2

|

INCH

MM |

1-1/2

38.1 |

3-15/32

88.10 |

2-9/16

65.08 |

2.067

52.50 |

13/16

20.63 |

|

2 ½

|

INCH

MM |

1-9/16

39.68 |

4-1/16

103.18 |

3

76.2 |

2.469

62.71 |

3/4

19.05 |

|

3

|

INCH

MM |

1-3/4

44.45 |

4-13/16

122.23 |

3-11/16

93.66 |

3.068

77.93 |

15/16

23.81 |

|

3 ½

|

INCH

MM |

1-11/16

42.86 |

5-3/8

136.52 |

4-7/16

112.71 |

3.548

90.12 |

11/16

17.46 |

|

4

|

INCH

MM |

1-7/8

47.62 |

5-31/32

151.60 |

4-3/4

120.65 |

4.026

102.26 |

1-1/16

26.98 |

|

5

|

INCH

MM |

2-5/8

66.67 |

7-5/16

185.73 |

5-9/16

141.28 |

5.047

128.19 |

1-11/32

34.13 |

|

6

|

INCH

MM |

2-3/4

69.85 |

8-5/8

219.07 |

6-11/16

169.86 |

6.065

154.05 |

1-13/32

35.71 |

REDUCING SIZES |

||||||

| NPS | Pressure Class 6000 - NPS 1/2 up to NPS 2 | |||||

| A | B | C | D | E | ||

|

1/2

|

INCH

MM |

1-1/4

31.75 |

1-23/32

43.65 |

3/4

19.05 |

0.466

11.84 |

7/8

22.22 |

|

3/4

|

INCH

MM |

1-7/16

36.51 |

1-61/64

49.60 |

1

25.4 |

0.614

15.60 |

7/8

22.22 |

|

1

|

INCH

MM |

1-9/16

39.68 |

2-7/16

61.91 |

1-5/16

33.33 |

0.815

20.70 |

15/16

23.81 |

|

1 ¼

|

INCH

MM |

1-5/8

41.27 |

2-23/32

69.05 |

1-1/2

38.1 |

1.160

29.46 |

13/16

20.63 |

|

1 ½

|

INCH

MM |

1-11/16

42.86 |

3-1/4

82.55 |

1-15/16

49.21 |

1.338

33.99 |

7/8

22.22 |

|

2

|

INCH

MM |

2-1/16

52.38 |

4-1/32

102.39 |

2-3/4

69.85 |

1.689

42.90 |

1-3/16

30.16 |

SIZE ON SIZE |

||||||

| NPS | Pressure Class 3000 - NPS 1/2 up to NPS 6 | |||||

| A | B | C | D | E | ||

|

1/2

|

INCH

MM |

1

25.4 |

1-3/8

34.92 |

15/16

23.81 |

0.622

15.80 |

17/32

13.49 |

|

3/4

|

INCH

MM |

1-1/16

26.98 |

1-5/8

41.27 |

1-3/16

30.16 |

0.824

20.93 |

15/32

11.90 |

|

1

|

INCH

MM |

1-5/16

33.33 |

2

50.8 |

1-7/16

36.51 |

1.049

26.64 |

23/32

18.25 |

|

1 ¼

|

INCH

MM |

1-5/16

33.33 |

2-3/8

60.32 |

1-3/4

44.45 |

1.380

35.05 |

9/16

14.28 |

|

1 ½

|

INCH

MM |

1-3/8

34.92 |

2-7/8

73.02 |

2

50.8 |

1.610

40.89 |

21/32

16.66 |

|

2

|

INCH

MM |

1-1/2

38.1 |

3-1/2

88.9 |

2-9/16

65.08 |

2.067

52.50 |

15/16

23.81 |

|

2 ½

|

INCH

MM |

1-9/16

39.68 |

4-1/16

103.18 |

3

76.2 |

2.469

62.71 |

3/4

19.05 |

|

3

|

INCH

MM |

1-3/4

44.45 |

4-13/16

122.23 |

3-11/16

93.66 |

3.068

77.93 |

15/16

23.81 |

|

3 ½

|

INCH

MM |

1-11/16

42.86 |

5-3/8

136.52 |

4-7/16

112.71 |

3.548

90.12 |

11/16

17.46 |

|

4

|

INCH

MM |

1-7/8

47.62 |

6-1/16

153.98 |

4-3/4

120.65 |

4.026

102.26 |

1-1/16

26.98 |

|

5

|

INCH

MM |

2-7/16

61.91 |

7-1/4

184.15 |

5-1/4

133.35 |

5.047

128.19 |

1

25.4 |

|

6

|

INCH

MM |

2-11/16

68.26 |

8-11/16

220.66 |

6-1/16

153.98 |

6.065

154.05 |

1-3/16

30.16 |

Bangdong Supply Alloy Steel Forged Thredolet,Alloy Steel Forged Brazolet,Steel Welding Boss.Forged Weldolet,Our production range includes Olet Pipe Fittings such as weldolet, sockolet, threadolet, laterolet, elbolet, nipolets and sweepolets. We can also manufacture and supply forged flanged outlet fitting in Class 150 to Class 2500 flange ratings. Lateral and elbow olets can be supplied in butt-weld, socket-weld, and threaded end connections. Weld pipe olet or Weldolet is one of the most commonly used branch connection fitting. It is widely considered a buttweld fitting, as it is welded onto the outlet of the pipe. A welding outlet helps in minimizing the stress concentrations and provides integral reinforcement without the need for reinforcing the weld.

Carbon Steel Pipe Welding Outlet Key Specifications / Features

Type: Pipe Welding Outlet / Pipe Olet/Weldolet Threadolet Socket Fittings

Manufacturing standards: ANSI/ASME B16.11/MSS-SP-79/MSS-SP-83/MSS-SP-95/MSS-SP-97

Size range: 1/8 to 4 inches (DN6-DN100)

Pressure: 2,000, 3,000, 6,000, 9,000lbs (Sch40, Sch80/Xs Sch160 Xxs)

Materials: carbon steel, stainless steel

Applications industries: petroleum, electric power, chemical industry, light industry, metallurgy, the shipping, urban construction and other professions

Type: Pipe Weldolet / Pipe Olet

Manufacturing standards: ANSI/ASME B16.11/MSS-SP-79/MSS-SP-83/MSS-SP-95/MSS-SP-97/Msssp75 Olet

Size range: 1/8 to 4 inches (DN6-DN100)

Pressure: 2,000, 3,000, 6,000, 9,000lbs (Sch40, Sch80/Xs Sch160 Xxs)

Materials: carbon steel, stainless steel

Applications industries: petroleum, electric power, chemical industry, light industry, metallurgy, the shipping, urban construction and other professions

ASTM A105 Weldolet Specification

Variations:

3000# & 6000#

But-weld : SCH10S – SCH40S – SCH80S – SCH160 – SCHXXS

Standards:

ASTM B564 – ASME SB564 – `Standard Specification for Nickel Alloy Forgings`

ASME B16.11 – `Forged Fittings Socket – Welding and Threaded`

MSS SP-97 – `Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded and Buttwelding Ends`

Size : 1/8″ NB to 4″ NB. (Socket weld & Threaded)

Class : 150, 3000, 6000, 9000

Dimensions:

Outlet : 1/2″ à 8″

Run pipe : 1/2″ à 60″

Stainless Steel – ASTM / ASME SA 182 F304, 304L, 304H, 309H, 310H, 316, 316H, 316L, 316 LN, 317, 317L, 321, 321H, 347, 347 H.

Carbon Steel – ASTM / ASME A105n Weldolet / ASME A 350 LF 2.

Alloy Steel – ASTM / ASME A 182 GR F 5, F 9, F 11, F 12, F 22, F 91.

Related Keywords