Aluminium Composite Panel Cladding

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1000 Square Meter

- Min. Order:

- 1000 Square Meter

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 7,000,000 sqm per year |

| Supply Ability: | 7,000,000 sqm per year |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | CE, IS9001 |

| HS Code: | 760612 |

| Transportation: | Ocean,Land,Air |

| Port: | Qingdao |

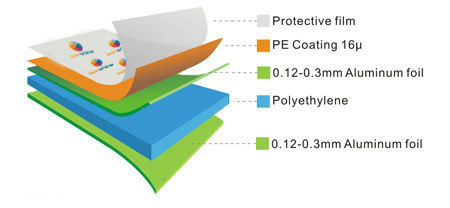

Alushine Sanwiches ACP is a dual sided sheet with one side in high gloss and the reverse in matte finish. Particularly suited to high wear environments, this robust Aluminum Composite Panel is the premium quality product is the range.

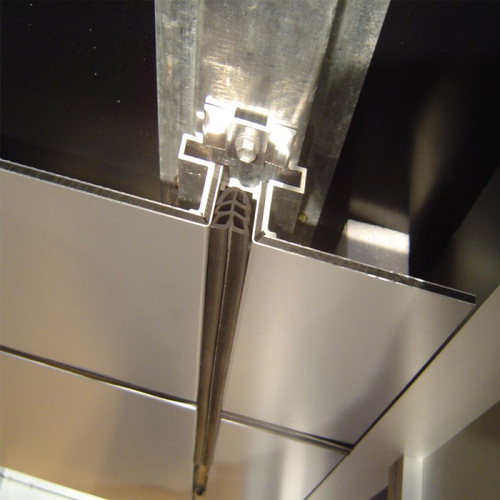

Alushine Aluminum Composite Sheet combines durability with flexibility. The ACP consist of a polyethylene core sandwiched between two aluminum skins. With the ability to be fabricated, folded and formed and with an extensive range of colours and finishes.

Application:

1) Constructional exterior curtain walls, Wall Panel are widely used in exhibition, stores, offices,

Banks, hotels, restaurants and apartments

2) Indoors decoration for interior wall, ceiling, bathroom, kitchen, balcony

3) Advertisement board, display platforms, billboards and signboards

4) Wallboard and ceilings for tunnels

5) Material used for vehicle bodies, yachts and boat and subway

| Technical Specifications | |

| Panel Thickness (mm) | 2, 3, 4, 5, 6, 7, 8 |

| Aluminum Skin Thickness (mm) | 0.21; 0.30; 0.40; 0.50 |

| Standard Sizes (mm): | 1000x2440 1000x3050 1220 x 2440 1220 x 3050 |

| 1500 x 3050 1500 x 4050 2000 x 3050 2000 x 4050 | |

| Dimensional Tolerances: | |

| Thickness (mm) | ± 0.2 |

| Width (mm) | ± 2 |

| Length (mm) | ± 3 |

| Diagonal (mm) | ± 5 |

| Thermal Expansion | 2.4mm/m @100˚C Temp Difference |

| Aluminum Thickness (mm) | Where applicable as specified in EN485-4 |

| Surface Properties: | |

| Paint Thickness (micron) | 20 |

| Pencil Hardness | >HB |

| Toughness of Coating | 3T |

| Temperature Resistance | -50˚C to +90˚C |

| Impact Strength (kg cm2) | 50 |

| Boiling Water Resistance | Boiling for 2hrs without change |

| Acid Resistance | Immerse Surface in 2% HC1 for 24hrs without change |

| Alkali Resistance | Immersed surface in 2% NaOH for 24hrs without change |

| Oil Resistance | Immerse Surface in 20# engine oil for 24hrs without change |

| Solvent Resistance | Cleaned 100 times with Dimethylbenzene without change |

| Cleaning Resistance | >1000 times without change |

| Peel Strength 180˚ | >5 Newton / mm |

| Panel Thickness Properties (mm) | 2 | 3 | 4 | 6 | 8 |

| Sound Absorbtion NRC | 0.05 | ||||

| Sound Attenuation Rw db | 23 | 24 | 25 | 26 | 27 |

| Water Absorbtion % By Volume | 0.01 | ||||

| Thermal Performance R Values | 0.0047 | 0.008 | 0.0113 | 0.018 | 0.0246 |

| Core Composition | LDPE | ||||

| Tensile Strength | 149MPa | ||||

Package & Loading

Related Keywords