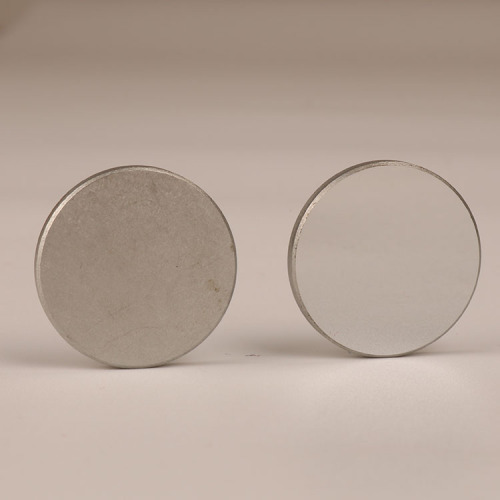

Reflective Mirrors Mo Metal D20mm

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 7-14 Days

- Transportation:

- Ocean, Air

- Port:

- Tianjin, Shanghai, Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Productivity: | 4000 |

| Supply Ability: | 4000 |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Transportation: | Ocean,Air |

| Port: | Tianjin,Shanghai,Qingdao |

JH laser company a enterprise to produce co2 laser tubes, ZnSe material laser focus lens, Silicon film reflector, Mo metal reflectors.

Co2 laser mirrors and focus lenses are important components of the laser light transmission system. In CO2 laser optical path, the coordination between reflector and focus lens constitutes a complete optical path.

Silicon and molybdenum is the main material of reflect mirror. The molybdenum mirror does not need coating film , they are able to work in harsh environments.Silicon reflect mirror is coated with gold or dielectric film, to improve the reflectivity of the mirror, then to improve the efficiency of the machine.

Laser will loss when it travels, so the laser machine need a higher reflectivity mirror.

2.Specifications:

Material: Gold-Plated Silicon

Diameter: 19.05 / 20 / 25 / 30 / 38.1mm

Thickness: 3mm (Dia.38.1mm Thk.5mm)

Good Reflectivity. The Reflectivity of Cloudray Mirrors Can Reach to 99.5%.

Gold-Plated Coating Film, More Durable.

Can Withstand 200 Watt Laser Power.

3.Silicon and Molybdenum is the main material of reflect mirror. The molybdenum mirror does not need coating film, which is able to work in harsh environments.

4.Silicon reflective mirror is coated with gold film to improve the reflectivity of the mirror and the efficiency of the cutting machine.

5.For Molybdenum mirror, there is no coating on the surface, but the reflection is low, maybe 80%.

For silicon mirror, it is coated with dielectric or golden film. Golden mirror is better than Mo mirror, as the reflection is higher.

Requirements for conventional processing of reflective mirror

|

Base material: |

Mo |

|

Form tolerance: |

+0.0/-0.1mm |

|

Thickness tolerance: |

±0.1mm |

|

Type: |

λ/4 632.8nm |

|

Finish: |

Mo:40-20,S2:Sperm membrane |

|

Parallelism: |

<1' |

|

Effective aperture: |

>90% |

|

The down side: |

<0.2×45° |

|

Coating: |

High reverse coating |

|

mirror |

|||||||

|

Mode |

Diameter |

Thickness |

Incidence angle |

Base material |

|

||

|

mm |

inch |

mm |

inch |

||||

|

JH-12-2 |

12 |

0.47 |

2 |

0.08 |

45 |

Mo |

|

|

JH-12.7-2 |

12.7 |

0.50 |

2 |

0.08 |

45 |

Mo |

|

|

JH-13-2 |

13 |

0.51 |

2 |

0.08 |

45 |

Mo |

|

|

JH-15-2 |

15 |

0.59 |

2 |

0.08 |

45 |

Mo |

|

|

JH-15-3 |

15 |

0.59 |

3 |

0.12 |

45 |

Mo |

|

|

JH-16-2 |

16 |

0.63 |

2 |

0.08 |

45 |

Mo |

|

|

JH-16-3 |

16 |

0.63 |

3 |

0.12 |

45 |

Mo |

|

|

JH-19-3 |

19 |

0.75 |

3 |

0.12 |

45 |

Mo |

|

|

JH-20-3 |

20 |

0.79 |

3 |

0.12 |

45 |

Mo |

|

|

JH-25-3 |

25 |

0.98 |

3 |

0.12 |

45 |

Mo |

|

|

JH-25.4-3 |

25.4 |

1.00 |

3 |

0.12 |

45 |

Mo |

|

|

JH-30-3 |

30 |

1.18 |

3 |

0.12 |

45 |

Mo |

|

|

JH-38.1-4 |

38.1 |

1.50 |

4 |

0.16 |

45 |

Mo |

|

|

JH-38.1-5 |

38.1 |

1.50 |

5 |

0.20 |

45 |

Mo |

|

|

JH-38.1-6 |

38.1 |

1.50 |

6 |

0.24 |

45 |

Mo |

|

|

JH-38.1-9 |

38.1 |

1.50 |

9 |

0.35 |

45 |

Mo |

|

|

JH-50-5 |

50 |

1.97 |

5 |

0.20 |

45 |

Mo |

|

|

JH-50.8-5 |

50.8 |

2.00 |

5 |

0.20 |

45 |

Mo |

|

|

JH-50.8-6 |

50.8 |

2.00 |

6 |

0.24 |

45 |

Mo |

|

|

JH-50.8-9 |

50.8 |

2.00 |

9 |

0.35 |

45 |

Mo |

|

|

JH-50.8-10 |

50.8 |

2.00 |

10 |

0.39 |

45 |

Mo |

|

Related Keywords