Mineral processing froth pumps handle frothy slurries

-

$5000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express, Express

- Port:

- Tianjin, Qingdao, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 200sets per month |

| Supply Ability: | 200Sets per month |

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,Express Delivery |

| Certificate: | ISO , CE |

| HS Code: | 8413709990 |

| Transportation: | Ocean,Land,Air,Express,Express |

| Port: | Tianjin,Qingdao,Guangzhou |

Mineral processing froth pumps handle frothy slurries

Froth pumps/frothy pumps/Ni-hard froth pumps/high chrome alloy iron pumps/100af froth pumps

3qv-af froth pumps /mineral processing froth pumps/froth pumps handle frothy slurries

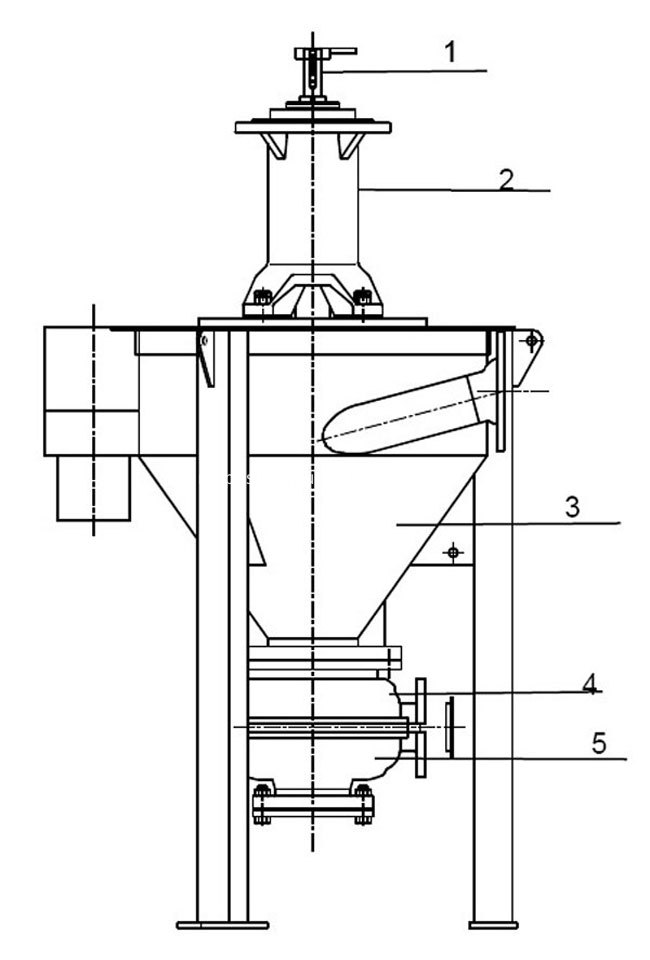

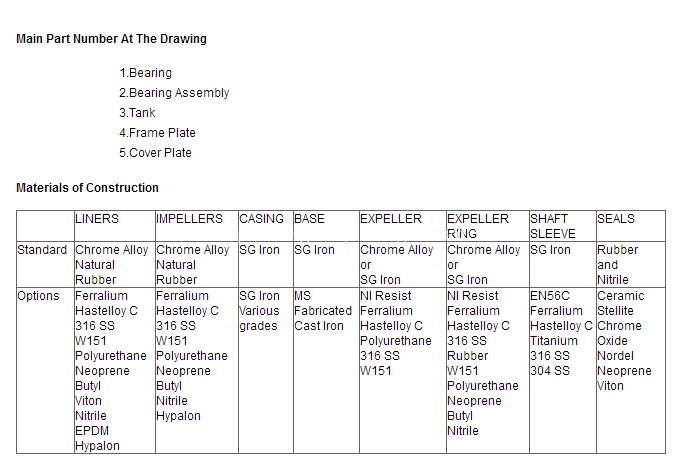

The construction of the froth pump is double casings slurry pump.All wet-parts can be supplied in Ni-hard,high chrome alloy iron and pressure-moulded natural or synthetic rubber.

Features

Submersed in the slurries,the NP-AF series froth pump is typically used to convey abrasive or corrosive frothy slurries.

2.A typical feature of this vertical centrifugal slurry pump is the double-casing design which allows the case to be split open along its centerline.Wet end parts are replaceable and made of abrasion-resistant high-chrome.Depending on your specific pumping task,we can rubber and polyurethane to construct the internal pump liner and impeller.

3.The impeller vanes and hopper are specially made to remove any foam produced during pumping operation.

4.Eliminate the need for any shaft seal and sealing water.

5.Parts submerged in the slurry can be made of metal or rubber.

Advantages

1.Simple pump system layout allows easy installation.

2.Transmission parts of this submersible pump are interchangeable with those of AF series.Installed above the bearing assembly is a motor mounting base or support frame.Flexible coupling or V-Belt is used to connect the motor shaft and the pump shaft.Pump shaft speed is easily adjusted by changing the grooved pulley so as to suit the varying pumping applications.

3.The hopper features a steely structure,complete with the tangential inlet and overflow box.The overflow box can easily send the excessive slurry back to the recycling tank.The tangential inlet allows the frothy slury to enter into froth pump while separating the air out of the slurry.

4.The pumping unit is interchangeable with the AH series.According to the kind of medium to be pumped ,we can use metal,rubber,or other non-metallic materials to make the wet-end parts of this froth pump.

5.The pump is able to function properly when there is insufficient suction.

Typical Applications---

Minerals Flotation Processing

Handle Frothy Slurries

NP-AF Froth Pump Showing Component

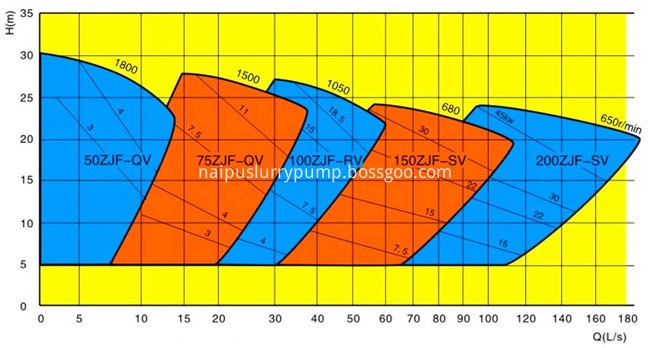

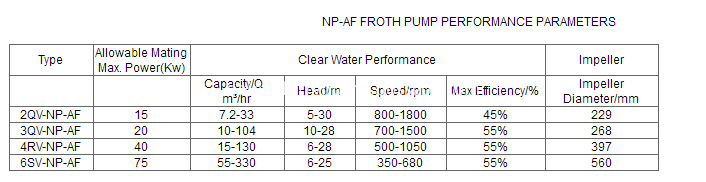

NP-AF FROTH PUMP SELECTION CHART

Product Overview:

Workshop Photos:

Assembly Pumps:

Quality Control:

Working At Site:

Contact US:

Shijiazhuang Naipu Pump Co.,Ltd

Add: No.368 Xinshi North Road,Shijiazhuang Hi-Tech Industry Development Zone Hebei,China 050091

Skype: karen_naipump

Contact Person:Karen Tan

If you have any query,please contact us freely.

Related Keywords