3/2C slurry pump for mill discharge

-

$1200.00≥1 Piece/Pieces

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express, Express

- Port:

- Tianjin, Qingdao, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 200sets per month |

| Supply Ability: | 200Sets per month |

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,Express Delivery |

| Certificate: | ISO , CE |

| HS Code: | 8413709990 |

| Transportation: | Ocean,Land,Air,Express,Express |

| Port: | Tianjin,Qingdao,Guangzhou |

Detailed specification of HEAVY DUTY type slurry pump

2.Long bearing life: The bearing assembly is with large diameter shaft and short overhang.

3. Wear resistant and anti abrasion wet parts: High chrome alloy and rubber etc. They are completely interchangeable with each other

4. Easily replaceable liners: Liners are bolted to the casing.

5. Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing.

6 Discharge direction can be positioned at intervals of 45 degrees

7. Simple maintenance throat bush: the mating face of the throat bush is tapered, so the wear is reduced and removal is simple.

8. Sealing type: pcking seal,impeller sealing and mechanical seal.

9. Widely application: They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial departments

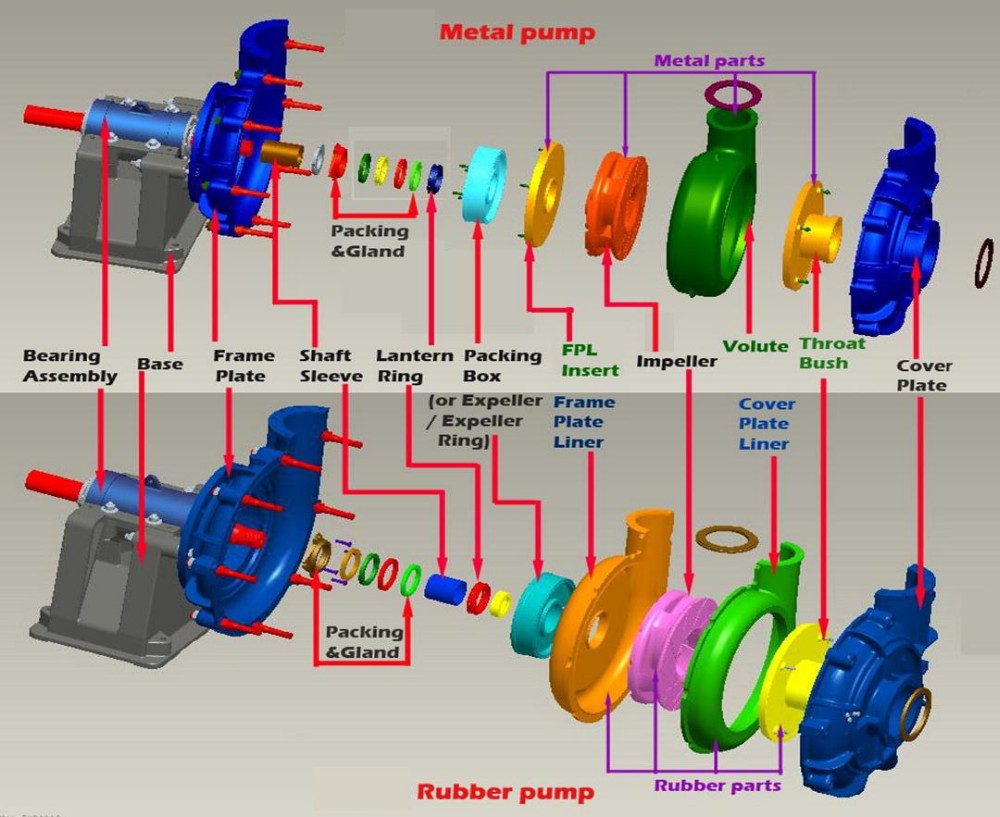

Construction design of mining slurry pump

The frame plates of this pump have changeable, hard metal or rubber liners. The impellers are made of wear-resistant metal or rubber.

The shaft seal of this kind of slurry pump could use the packing seal, centrifugal seal.

The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications.

The pump of this type may be installed in multistage series to meet the delivery for long distance.

2.Advantage of Horizontal slurry pump, mining slurry pump1. Advanced water design, reasonable structure design, good cavitation performance, reliable operation etc features , which is used in metallurgy, mine, non-ferrous metal, electricity, coal etc to transport tailings, fine ore, ash, slime, gravel etc strong abrasive and high concentration slurry.

2. Adjusting gap is available. Small gap, high efficiency, less leakage. After a period of running, the impeller and guard plate have some wear, so that the efficiency of pump decrease, but by adjusting the gap between impeller and guard plate the efficiency of pump will reach the highest value again.

3. Product commonality. Our products are all international standard, parts can be interchangable.

4. Wear resistant and anti-corrosive material. Cr28 is a kind of material which is increased some Cr content on the basis of Cr26, and adding a certain amount of Mo,Ni,Ti,W,Cu,Re etc rare metal, thereby hardenability is increased and promote the formation of carbides MoC, the material has a higher wear resistance.

3. Structure of AH mining slurry pump,heavy duty AH slurry pump, 8/6F-AHR Rubber Liners Slurry Pump

4. Production process of our vertical slurry pump,horizontal slurry pump,submersible slurry pump:8/6F Rubber Liners Slurry Pump

5. Package of our heavy duty slurry pump

Related Keywords