bearing assembly B005 C005

-

$1200.00≥1 Piece/Pieces

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express, Express

- Port:

- Tianjin, Qingdao, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 200sets per month |

| Supply Ability: | 200Sets per month |

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,Express Delivery |

| Certificate: | ISO , CE |

| HS Code: | 8413709990 |

| Transportation: | Ocean,Land,Air,Express,Express |

| Port: | Tianjin,Qingdao,Guangzhou |

slurry pumps bearing assemblyis one type of bearing assembly used in slurry pumps.

slurry pumps bearing cylinders made in China with good quality and short delivery time.

slurry pump rotors made in China , we also accept OEM orders for bearing housing, bearing body, bearing assembly with ductile iron or grey iron.

The bearing assembly is one of the main parts for slurry pump parts, we produce grey iron or ductile iron,two types of different materials.

1. Product Application of slurry pumps bearing assembly

We also offer OEM service for worldwide customers and can manufacture slurry pumps according to construction drawing and samples.

Pump S004 Bearing Cylinder, Pump F004 Bearing Housing, slurry pumps bearing assembly part No.: B005,C005,D005,E005,F005,EAM005,DAM005,FAM005,etc.

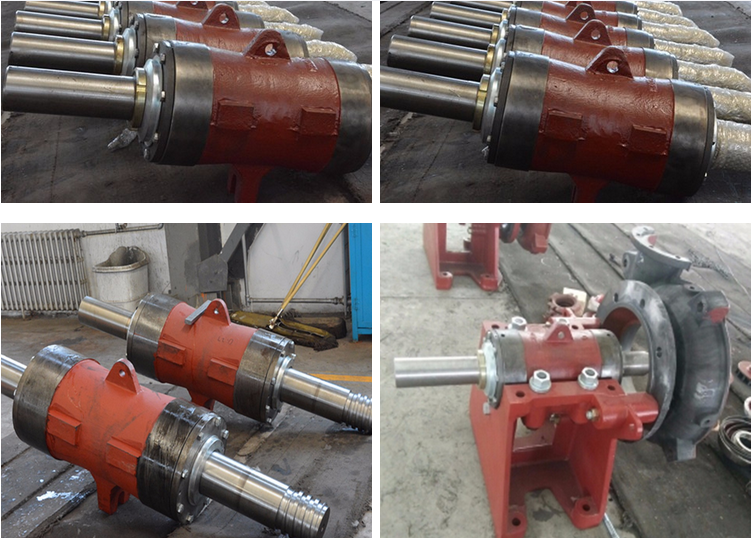

Pictures of slurry pumps Bearing assembly for horizontal slurry pumps/EAM005/EEAM005 and vertical slurry pump,SV005,etc.

Pump S004 Bearing Cylinder, Pump F004 Bearing Housing.

4. The slurry pumps bearing assembly (EEAM005,EAM005,F005,FAM005 etc) importance:

slurry Pumps S004 Bearing Cylinder, Pump F004 Bearing Housing

The precision of bearing`s assembly has a direct influence on bearing`s service life, Shijiazhuang naipu assembles the bearing in strict accordance with national standards

Before put the new bearing into the bearing housing, we will ensure the bearing and bearing housing are all absolutely clean. Heating the bearing in the 70~80℃ oil, and then mount it on the main shaft. The assembly should not be forced, in order to avoid injury of the shaft.

Related Keywords