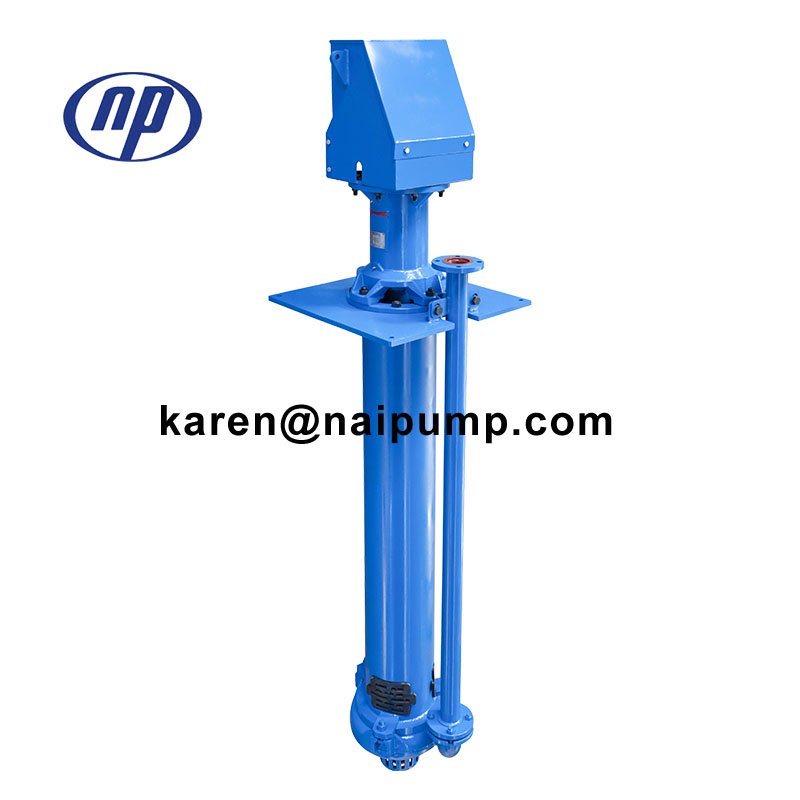

65QV-SP metal lined vertical sump pump

-

$1600.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express, Express

- Port:

- Tianjin, Qingdao, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 200sets per month |

| Supply Ability: | 200Sets per month |

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,Express Delivery |

| Certificate: | ISO , CE |

| HS Code: | 8413709990 |

| Transportation: | Ocean,Land,Air,Express,Express |

| Port: | Tianjin,Qingdao,Guangzhou |

65QV-SP Metal Lined Vertical sump pumps

Naipu® NP-SP pumps are vertical, centrifugal slurry pumps submerged in sump to work.They are designed for delivering abrasive,large particle and high density slurries.These pumps have no need of any shaft seal and sealing water. They can also be operated normally for insufficient suction duties.Wet parts of type NP-SP pump are made of abrasion-resistant metal. All parts of type NP-SP(R) pump immersed in liquid are lined with rubber outer liner.They are suited to transport non-edge angle abrasive slurry.

Features

1.Submersed in water and sitting on the bottom of the sump,the SP series vertical sump pump is commonly used to convey high-viscosity slurries with highly abrasive,coarse particles.

2.A key feature of this sump pump is the one-piece pump housing.Wet-end parts are replaceable and made of high-chrome for maximum corrosion resistance.Rubber and polyurethane are selected to make the pump liner and impeller.The sump pump can be used for different pumping applications.

3.Various types of impellers are designed to handle different pumping tasks.

4.Vertical cantilever design eliminates the need of shaft seal or sealing water.

5.Parts submerged in the slurry can be made of metal or rubber.

Advantages

1.The phydical layout of the submersible sump pump simplifies maintenance operations.

2.The sump pump body is bolted to the support plate.On top of the support plate sits the bearing assembly.Closer to the pump end is a double-row tapered roller bearing.Connected to the drive end is a single-row cylindrical roller bearing.

3.Installed on the bearing assembly is a motor support frame,or motor mounting base, where the motor is mounted.Flexible coupling or drive belt connects the motor shaft and the pump shaft.

4.Without any shaft seal or sealing water,the centrifugal sump pump can function properly even when there is insufficient slurry getting to the suction side.

5.A screen filter is set at the suction side to separate large particles out of the slurry.

Installation Types

DC: The motor mounting base is set above the bearing assembly,so it is easy to replace or repair the motor parts.

BD: A V-belt is used to connect the motor shaft and the pump shaft.The motor support frame is installed above the bearing assembly,allowing easy replacement of grooved wheels.The purpose of swapping grooved wheels is to change the rotary speed of the pump shaft in order to suit varing pumping applications or conform to the worn-down sump pump.

Sump drainage washdown

Floor drainage

Mill sumps

Carbon transfer

Monitoring

Magnetite mixing

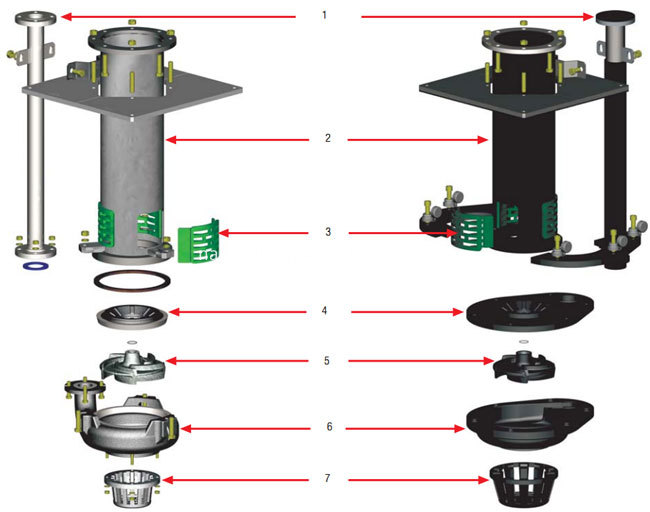

NP-SP(R) Sump Pump Showing Component

Main Part No.At the Drawing

1.Discharge Pipe

5.Impeller

2.Column

6. Pump Casing

3.Strainer

7.Lower Pipe

4.Back Liner

Pump Type

Allowable Mating Max. Power(Kw)

Range Of Performance

Impeller

Capacity/Q

Head/m

Speed/rpm

Max Efficiency/%

No. of Vanes

Impeller Diameter/mm

m³/hr

L/S

40PV-NP-SP

15

19.44-43.2

5.4-12

4.5-28.5

1000-2200

40

5

188

65QV-NP-SP

30

23.4-111

6.5-30.8

5-29.5

700-1500

50

5

280

100RV-NP-SP

75

54-289

15-80.3

5-35

500-1200

56

5

370

150SV-NP-SP

110

108-479.16

30-133.1

8.5-40

500-1000

52

5

450

200SV-NP-SP

110

189-891

152.5-247.5

6.5-37

400-850

64

5

520

250TV-NP-SP

200

261-1089

72.5-302.5

7.5-33.5

400-750

60

5

575

300TV-NP-SP

200

288-1267

80-352

6.5-33

350-700

50

5

610

Pump Performance Parameters

NP-SP Materials of Construction

IMPELLERS

CASING

COLUMN

DISCHARGE

SEALS

Standard

High Chrome Alloy Rubber

High Chrome Alloy Rubber

Mild Steel Mild Steel Rubber Lined

Mild Steel Mild Steel Rubber Lined

Natural Rubber

Options

Butyl EPDM Hypalon

Polyurethane 316SS W151

Neoprene

Butyl EPDM Hypalon Nitrile 316SS W151

Neoprene Butyl Nitrile 316SS

Neoprene

Butyl

Nitrile 316SS

Nordel Neoprene Viton Hypalon Butyl EPDM

Vertical sump pumps/centrifugal slurry pumps/vertical pumps delivering abrasive slurries/sump pumps/abrasion-resistant metal sump pumps/65qv sump pumps/100RV sump pumps/vertical pumps transporting non-edge angle abrasive slurry.

Product Overview:

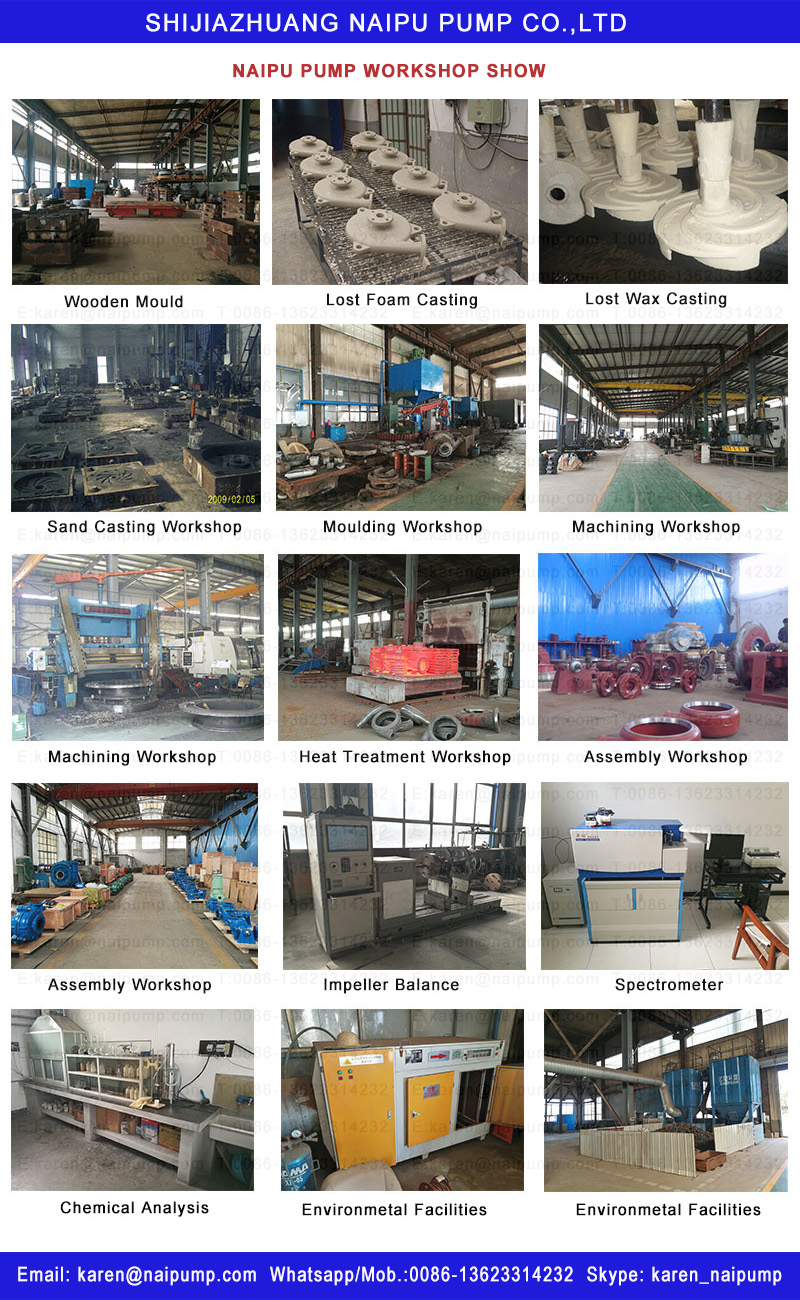

Workshop photos:

NAIPU PUMP is a whole processing company, Start from Modeling Workshop,Casting Workshop,Heat treatment Workshop,Machining Workshop ,Assembly Workshop and Pump Testing Workshop are all by us. So we are modernization and integrated company to satisfy the requirement of the changing needs of market.

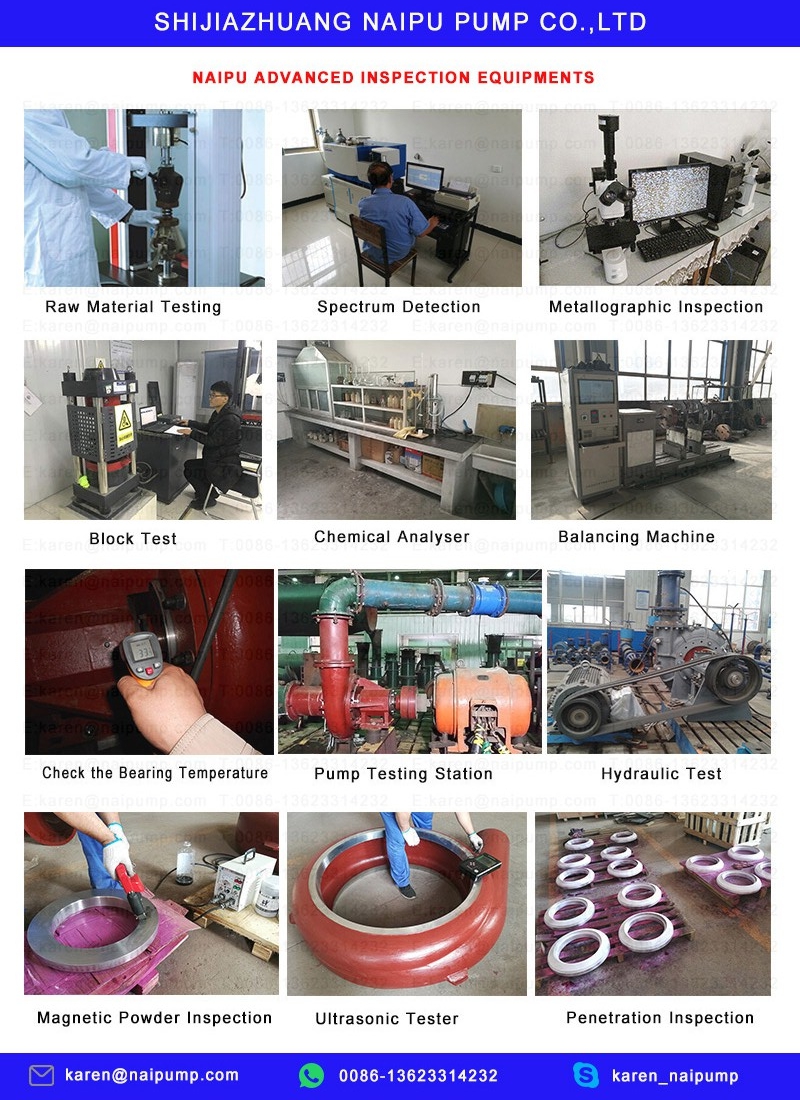

Quality Control System

CONTACT US:

SHIJIAZHUANG NAIPU PUMP CO.,LTD

ADD:NO.368 XINSHI NORTH ROAD,SHIJIAZHUANG HI-TECH INDUSTRY DEVELOPMENT ZONE HEBEI,CHINA 050091.

CONTACT PERSON:KAREN TAN

SKYPE: KAREN_NAIPUMP

PLEASE CONTACT ME FREELY IF ANY QUESTIONS.

Keywords

Vertical sump pumps/centrifugal slurry pumps/vertical pumps delivering abrasive slurries/sump pumps/abrasion-resistant metal sump pumps/65qv sump pumps/100RV sump pumps/vertical pumps transporting non-edge angle abrasive slurry.

Related Keywords