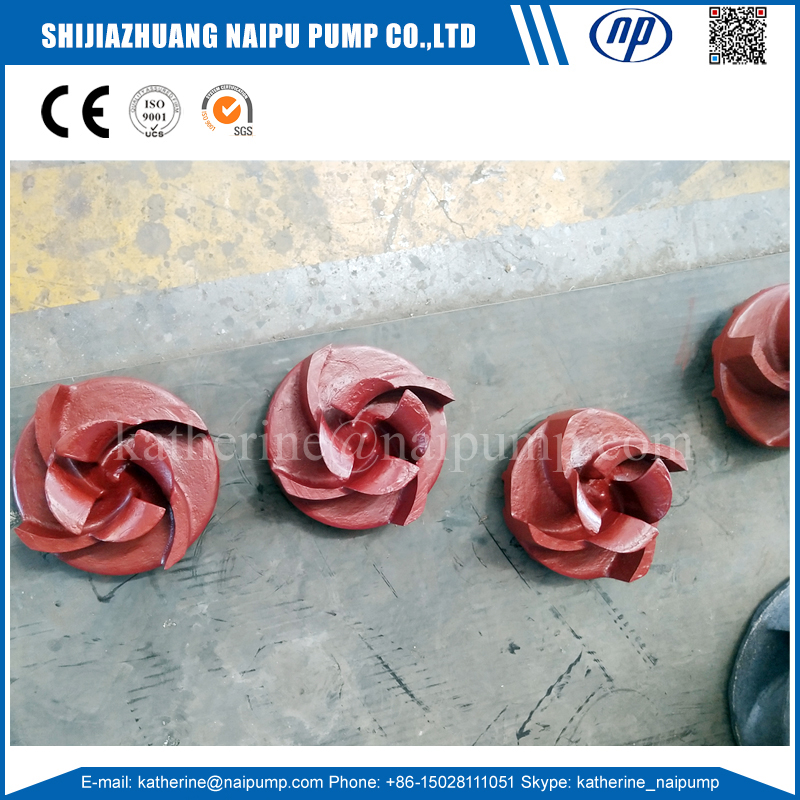

Naipu SPR65206S02 Open Impeller for 65QV Sump Pump

-

$120.00≥1 Piece/Pieces

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express, Express

- Port:

- Tianjin, Qingdao, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 200sets per month |

| Supply Ability: | 200Sets per month |

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,Express Delivery |

| Certificate: | ISO , CE |

| HS Code: | 8413709990 |

| Transportation: | Ocean,Land,Air,Express,Express |

| Port: | Tianjin,Qingdao,Guangzhou |

Naipu SPR65206S02 Open Impeller for 65QV Sump Pump

Small Semi-open Impeller, Ceramic impeller for pump, 6 inches froth pump impeller, horizontal pump impeller.

W RT Slurry pump parts, A H centrifugal pump impeller, closed ceramic impeller,

SPR65026AS02, SPR65092R, SPR65041R, SPR65153R...

Some typical examples of the need for the non-standard impellers are:

a) Pumping coarse coal

Large particles may cause blockages with a standard 5 vane closed impeller. A special large-particle 4 vane impeller may be required.

b) Pumping fibrous material

Long Fibres may get caught around the vane entrance of standard impellers. A special chokeless impeller can be used for these duties.

c) Reduced diameter impellers

In some special cases, reduced diameter impellers are required but are generally avoided as impeller wear is higher than with full diameter impellers.

d)Reduced eye impellers

In some extremely high wearing applications such as mill discharge, a special impeller with a reduced eye can prolong impeller wear life.

A H horizontal slurry pump and parts

Slurry pumps are used widely throughout the beneficiation section of the mining industry where most plants utilise wet separation systems. These systems usually require the movement of large volumes of slurry throughout the process.

Slurry pumps are also widely used for the disposal of ash from thermal power plants. Other areas where slurry pumps are used include the manufacture of fertilisers, land reclamation, mining by dredges, and the long distance transportation of coal and Minerals.

Increased global focus on environmental and energy constraints will certainly generate much wider uses for slurry pumping in years to come.

Slurry Pump impeller / Slurry Pump Parts Material Selection

| Impeller Code | HA Slurry Pump | Materials |

| B1127 | 1.5/1B-HA | High chrome, Natural rubber, Polyurethane |

| B15127 | 2/1.5B-HA | High chrome, Natural rubber, Polyurethane |

| C2147 | 3/2C-HA | High chrome, Natural rubber, Polyurethane |

| C2127 | 3/2C-HA | High chrome, Natural rubber, Polyurethane |

| C2051 | 3/2C-HA | High chrome, Natural rubber, Polyurethane |

| D3147 | 4/3C-HA, 4/3D-HA | High chrome, Natural rubber, Polyurethane |

| D3145HE1 | 4/3C-HA, 4/3D-HA | High chrome, Natural rubber, Polyurethane |

| D3021 | 4/3C-HA, 4/3D-HA | High chrome, Natural rubber, Polyurethane |

| E4147 | 6/4D-HA, 6/4E-HA | High chrome, Natural rubber, Polyurethane |

| E4056 | 6/4D-HA, 6/4E-HA | High chrome, Natural rubber, Polyurethane |

| E4058 | 6/4D-HA, 6/4E-HA | High chrome, Natural rubber, Polyurethane |

| F6147 | 8/6E-HA, 8/6F-HA, 8/6R-HA | High chrome, Natural rubber, Polyurethane |

| F6056 | 8/6E-HA, 8/6F-HA, 8/6R-HA | High chrome, Natural rubber, Polyurethane |

| F6021 | 8/6E-HA, 8/6F-HA, 8/6R-HA | High chrome, Natural rubber, Polyurethane |

| F6058HE1 | 8/6E-HA, 8/6F-HA, 8/6R-HA | High chrome, Natural rubber, Polyurethane |

| FAM8147 | 10/8F-HA | High chrome, Natural rubber, Polyurethane |

| G8147 | 10/8ST-HA | High chrome, Natural rubber, Polyurethane |

| FAM10147 | 12/10F-HA | High chrome, Natural rubber, Polyurethane |

| G10147 | 12/10ST-HA | High chrome, Natural rubber, Polyurethane |

| FAM12147 | 14/12F-HA | High chrome, Natural rubber, Polyurethane |

| G12147 | 14/12ST-HA | High chrome, Natural rubber, Polyurethane |

| GAM14147 | 16/14TU-HA | High chrome, Natural rubber, Polyurethane |

| Impeller Code | L Slurry Pump | Materials |

| 175056 | 20A-L | High chrome, Natural rubber |

| 32056 | 50B-L | High chrome, Natural rubber |

| 43056 | 75C-L | High chrome, Natural rubber |

| 64056 | 100D-L | High chrome, Natural rubber |

| 86056 | 150E-L | High chrome, Natural rubber |

| 108056 | 200E-L | High chrome, Natural rubber |

| SL30147 | 300S-L | High chrome, Natural rubber |

| SL35147 | 350S-L | High chrome, Natural rubber |

| STL40147 | 400ST-L | High chrome, Natural rubber |

| STL45147 | 450ST-L | High chrome, Natural rubber |

| TUL55147 | 550TU-L | High chrome, Natural rubber |

| Impeller Code | M Slurry Pump | Materials |

| F8147 | 10/8E-M, 10/8F-M, 10/8R-M | High chrome, Natural rubber, Polyurethane |

| F10147 | 12/10F-M, 12/10R-M | High chrome, Natural rubber, Polyurethane |

| Impeller Code | HH Slurry Pump | Materials |

| CH1127 | 1.5/1C-HH | High chrome, Polyurethane |

| DH2147 | 3/2D-HH | High chrome, Polyurethane |

| EH3147 | 4/3E-HH | High chrome, Polyurethane |

| FH4147 | 6/4F-HH | High chrome, Polyurethane |

| FH6147 | 6S-H, 8/6S-H | High chrome, Polyurethane |

| Impeller Code | G(H) Gravel Pump | Materials |

| DG4137 | 6/4D-G, 6/4E-G | High chrome |

| EG6137 | 8/6E-G | High chrome |

| FG8137 | 10/8F-G, 10/8S-G | High chrome |

| FG10137 | 12/10G-G | High chrome |

| GG12137 | 14/12G-G | High chrome |

| FGH8137 | 10/8F-GH | High chrome |

| GGH10137 | 12/10G-GH | High chrome |

| TG14148 | 16/14TU-GH | High chrome |

| Impeller Code | SP Vertical Slurry Pump | Materials |

| SP4206 | 40PV-SP | High chrome, Natural rubber, Polyurethane |

| SP65206 | 65QV-SP | High chrome, Natural rubber, Polyurethane |

| SP10206 | 100RV-SP | High chrome, Natural rubber, Polyurethane |

| SP15206 | 150SV-SP | High chrome, Natural rubber, Polyurethane |

| SP20206 | 200SV-SP | High chrome, Natural rubber, Polyurethane |

| SP25206 | 250TV-SP | High chrome, Natural rubber, Polyurethane |

| SP30206 | 300TV-SP | High chrome, Natural rubber, Polyurethane |

Q1. How slurry pump works?

A: HH slurry pumps are those of cantilever, horizontal and centrifugal ones, which are widely used to transport corrosive/ abrasive and high concentration slurry in many industries.

Q2. How to gurantee the quality?

A: All our pump and spare parts pass ISO 9001:2008 and CE certificate. Warranty time is 12 month except wet end parts.

Q3. What information should be known if I want to get a quotation?

A: Pump working conditions, Usage , Pump Capacity, pump Head , Slurry SG, The More the Better. Please offer me the type of the used pump that working now.

Q4. Manaufacturer or trader?

A: Manufacturer of couse. Our Factory located in Shijiazhuang, Hebei , China. Welcome to visit.

Q5. Your company product range?

A: Centrifugal pump, Slurry pump, Sand pump, Gravel pump, Dredging pump, Clean water pump, Sewage pump, Chemical pump, Single stage pump, Double suction pump, Industry pump, Paper pulp pump, Mud pump, Sludge pump, etc

Q6. Delivery time:

A: For the Common Slurry pump and spare parts , the delivery time within 7-15 days. Special material and OEM production is longer.

Any question please contact Katherine Hou freely.

+86 150281115051

Related Keywords