Machine With Maize Thresher

-

USD3500≥1 Set/Sets

- Payment Type:

- L/C, T/T, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50 sets/month |

| Supply Ability: | 50 sets/month |

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO9001, CE, SGS, CIQ, SONCAP |

| HS Code: | 8437109000 |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin |

Maize Corn Cleaning Machine With Maize Thresher

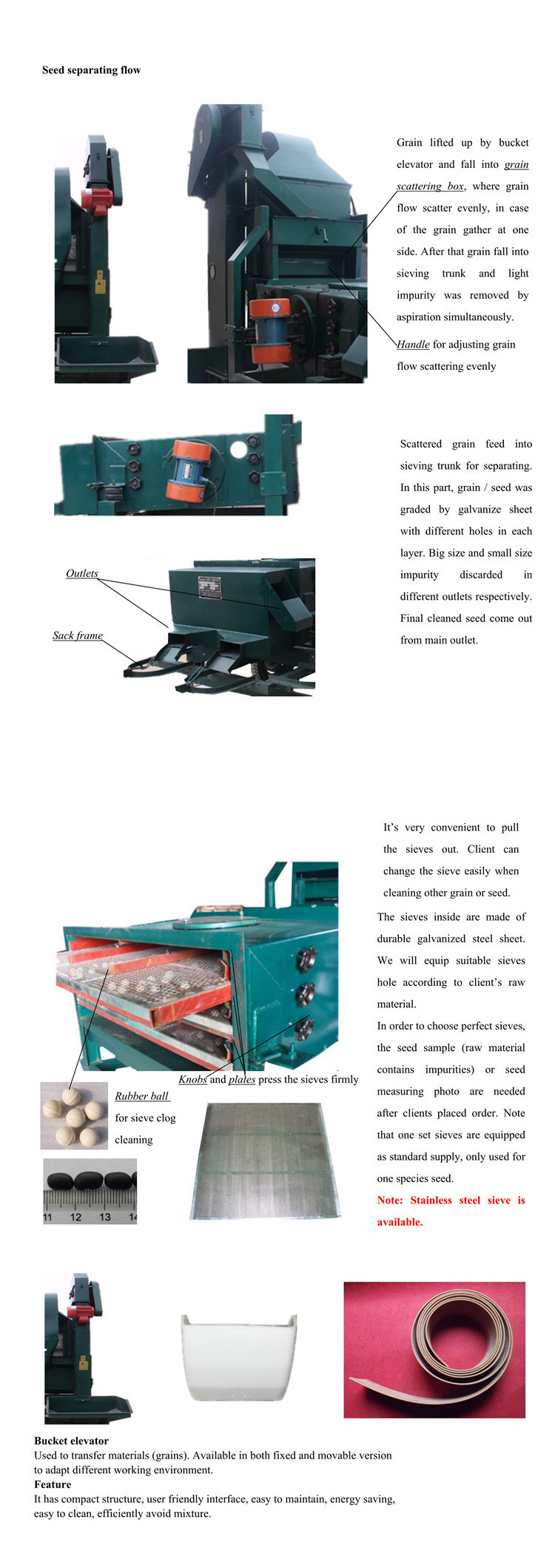

Introduction of Grain Cleaning Machine

The

5XZC-3A Seed Cleaner & Grader has a good cleaning effect on grain

seeds, tree seeds, forage seeds, beans, and a variety of commercial

grains. It can be equipped to suit a variety of special jobs and

purposes.

The 5XZC-3A Seed Cleaner is installed a maize thresher at front, so it will thresh the maize first, then dust and light impurity are removed by aspirator fan, material falls on sieve layers and was separated by sieves according to width and thickness difference. All the oversize and undersize impurities were discharged from outlets.

Features of Seed Cleaner Grader

Air screen cleaner becomes basic and most favourite cleaning machine in seed and grain industryof global market, with high efficiency, excellent performance, wide application.

It`s suitable for processing all kind of seeds, cereals, grains species and crops, such as wheat, paddy, rice, barely, maize, millet, cumin, sunflower seed, soybean ,coffee bean, cocoa bean ,oil seeds, etc.

Customized sieve layer amount and various machine combinations allow the seed cleaner & grader to be used for a wide range of applications and increase grading efficiency.

Working Principle

Grain fall into grain inlet box after air sieving, and then under the vibration the grain jumping and flow to the multi-layer sieving trunk, following the grains well-proportioned enter to the upper layer sieve via the rubber curtain. Selected grains will fall into the next lower sieving panel after sieving, chaff and debris blocked by sieves and transfer to the outlet of large impurity. The selected grains will fall into the lower layers sieving panels, and will be graded into different levels of the different grain sizes by sieving in different sieving layers, that caused by the layers sieving panels have different mash size. Selected grains flow to the outlets of good grain, fill into bag hung on the bag holder. Cap of outlets can be used when shift bagging that means the cap can be close when you change the bag. It is the whole work flow for the separator.

Use different sieve to different process of different type of grains. The observing windows on the sieving trunk are for checking operation.

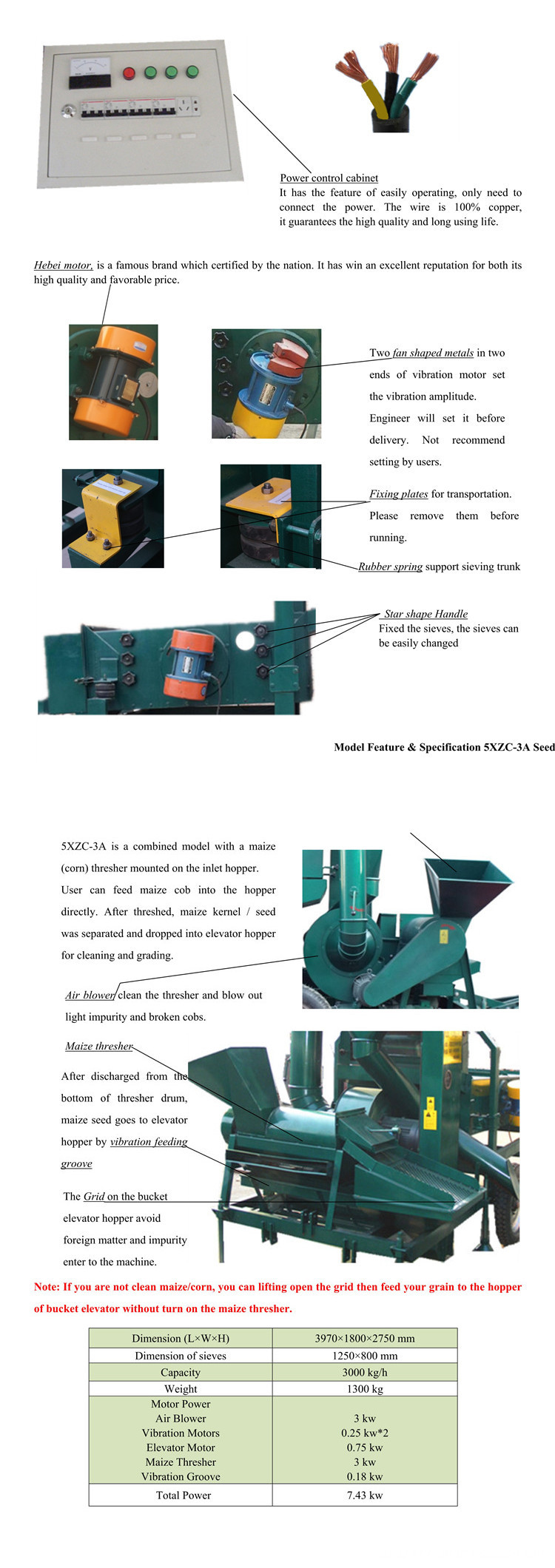

Specification of Maize Corn Cleaning Machine With Maize Thresher

|

Dimension (L×W×H) |

3970×1800×2750 mm |

|

Dimension of sieves |

1250×800 mm |

|

Capacity |

3000 kg/h |

|

Weight |

1300 kg |

|

Motor Power Air Blower Vibration Motors Elevator Motor Maize Thresher Vibration Groove |

3 kw 0.25 kw*2 0.75 kw 3 kw 0.18 kw |

|

Total Power |

7.43 kw |

Data of Similar Products

|

Model |

Capacity (tons/hour) |

Power (KW) |

Weight (KG) |

Dimension Length*Width*Height (mm) |

Feature |

|

5XZC-1 |

0.8 |

8HP |

800 |

1250×950×1100 mm (without diesel engine) |

1. Motor, 2.2KW (four-pole) 2. Diesel Engine, 8 HP 3. Diesel Engine (with electrical starter motor) |

|

5XZC-3A |

3 |

7.43 |

1300 |

3970*1800*2750 mm |

Installed Maize Thresher |

|

5XZC-3B |

3 |

4.25 |

1200 |

3970*1800*2750 mm |

Basic Cleaning and Grading |

|

5XZC-3C |

3 |

7.25 |

1300 |

3970*1800*2750 mm |

Installed Wheat Huller |

|

5XZC-3P |

3 |

9.75 |

1300 |

3970*1800*2750 mm |

Installed Paddy Thresher |

|

5XZC-5A |

5 |

12.74 |

1600 |

4650*2120*3100 mm |

Installed Maize Thresher |

|

5XZC-5B |

5 |

6.99 |

1500 |

4650*2120*3100 mm |

Basic Cleaning and Grading |

|

5XZC-5C |

5 |

10.99 |

1600 |

4650*2120*3100 mm |

Installed Wheat Huller |

|

5XZC-7.5F |

7.5 |

10.1 |

1800 |

5600*2000*3200 mm |

With Destoner Plate |

|

5XZC-7.5C |

7.5 |

14.85 |

2000 |

5600*2000*3200 mm |

Installed Wheat Huller |

|

5XZC-15A |

7.5 |

20.93 |

2200 |

5400×2450×3250 mm |

Installed Maize Thresher |

Photos and Details

Related Keywords