Customized Design Quality-assured Ground Screw Pile

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 120 Bag/Bags

- Min. Order:

- 120 Bag/Bags

- Delivery Time:

- 25 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 2000pieces/month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,Shanghai |

Customized Design Quality-assured Ground Screw Pile

Customized Design Quality-assured Ground Screw Pile is one type of high quality ground screw from Honde factory and there are more than 30 types of ground screw we produce and our engineer also can design good ground screw piles to you according to your requirements. The customized ground screw often can not allow to sale but honde ground screw design by ourselves can sale and we also can design as your needs. The logo of ground screw can be designed by you and make sure your brand can not copy.

|

Number |

HDFT76*1600 |

|

Length |

1600MM |

|

Out Pipe Dia |

76MM |

|

Pipe Thickness |

3MM |

|

Weight |

10KG |

|

Material |

ISO630 Fe A / Din EN10025 Fe 360 B |

|

Surface Finished |

Hot Dipped Galv. As standard DIN EN ISO 1461-1999 |

|

Delivery Time |

25 days after get 30% prepayment |

|

Payment |

L/C, T/T, D/P |

|

MOQ |

360 pcs |

|

Port |

Xingang |

|

Payment Term |

30% prepayment, the balance at sight B/L copy. |

|

Package |

120pcs/pallet 1616pcs/20`container |

Product Process

Step 1: Cutting

The length of welded pipe is 6 meters and the welded pipe need to be cut by sawing machine according to customer's need.

Step 2: Heating

Putting ground screw to high frequency heating machine and make ground screw be soft so that ground screw can be shaping.

Step 3: Shrinking

Using shrinkage machine to change the shape and diameter of ground screw.

Step 4: Punching

Using punching machine to do a hole or other for ground screw.

Step 5: Welding

The spiral blade of ground screw will be welded by automatic welding machine.

Step 6: Galvanizing

The surface treatment is acid picking and hot dip galvanizing.

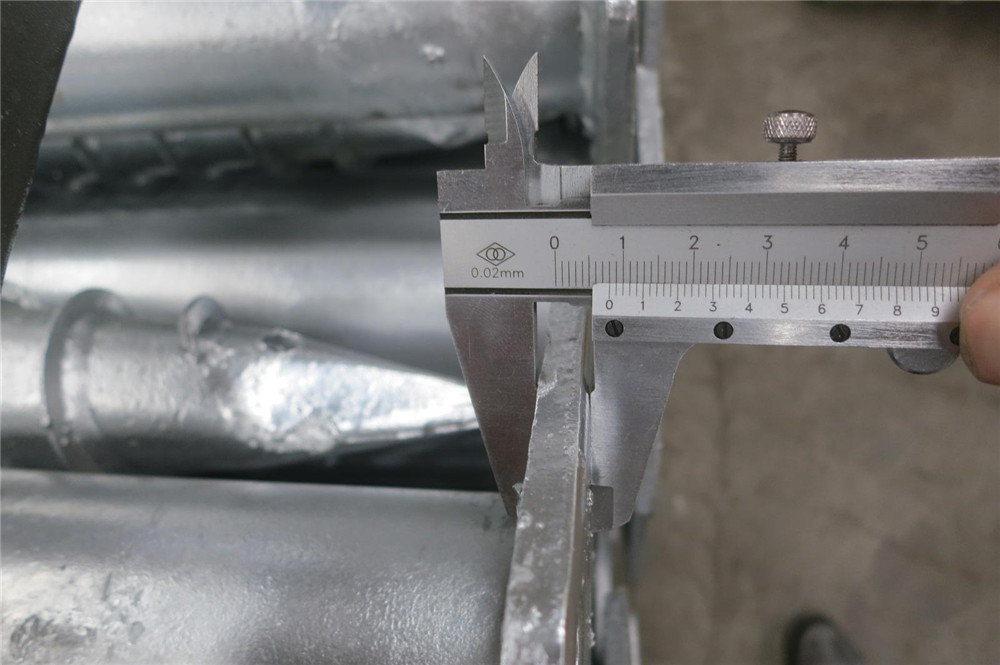

Step 7: Testing

Our quality control will test the goods and supply checking reports according to customer's need.

Step 8: Packing

Steel pallet is used to place ground screw and then wrap the pallet with multi-layer packaging to firm the ground screw.

Company Introduce

Hebei Honde Industrial Trade Imp&Exp Co., Ltd in Hebei province of China and established in 2002. We are manufacturer and exporter of ground screw, household foundations, professional foundations, solar foundations, pile driver, post anchor, earth anchor, beach umbrella anchor and solar mounting system.

We have built long-term business relationship with many companies around the world, such as KRINNER, ALDI, LIDL, KEMER and so on. We have been accepted by ISO9001 quality system and BSCI, BV, CE certification and have advanced automatic welding equipment. We sincerely hope have a good cooperation with you.

Related Keywords