High Pressure Aluminum Gravity Casting

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA, CPT

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100 Ton/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin |

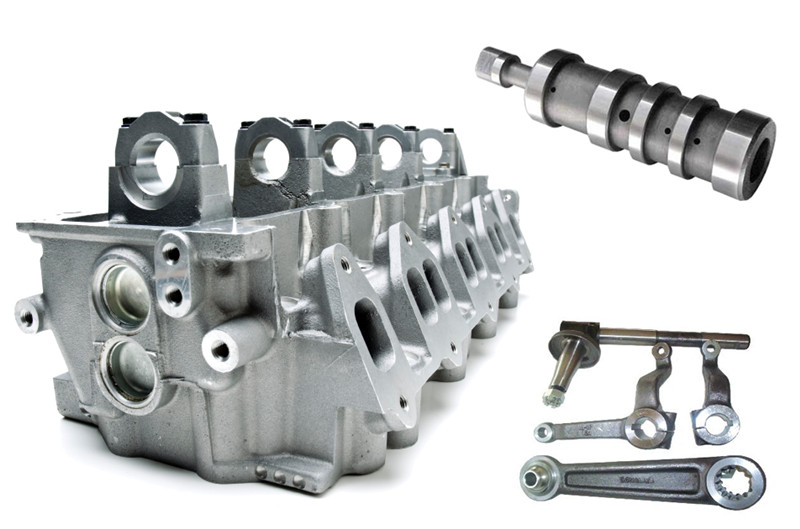

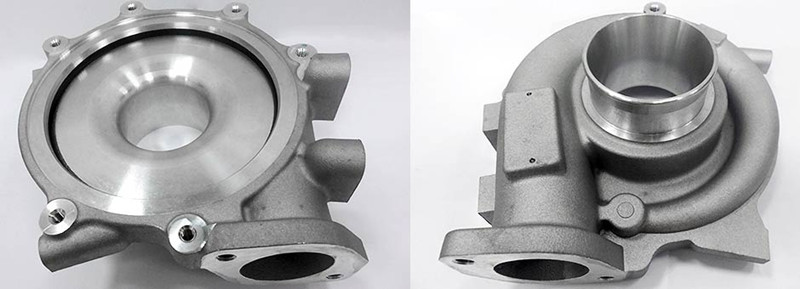

Aluminum Gravity Casting

Unlike aluminum die casting, gravity casting is the casting technique that utilizing gravity to fill the mould with liquid aluminum alloy. Such gravity casting can also be called as aluminum gravity die casting or aluminum permanent mold casting.

Aluminum Gravity Casting Process

Like other casting processes, aluminum gravity casting process starts from the developping of mold by CNC machines. Then, melt aluminum ingots into liquid status, and pour the aluminum liquid water into the permanent molds to fill the cavity by handwork or by gravity casting machines. Next, cool the poured aluminum alloy for a while for solidification.Finally, take the aluminum gravity casting blanks from the mould, and remove the flash and carry out necessary post operations like shot blasting, machining and others. Below is a video showing the aluminum gravity casting process in our foundry.

Benefits of Aluminum Gravity Casting

- The tolerances and surface finish are good.

- Gravity die casting method is competitive casting method when production quantity is relatively small or when heat treatment is needed to improve the mechanical properties.

- This casting method gives better tolerances and surface finish than sand casting. But the tooling costs are a bit higher than by sand casting.

- Using sand cores in gravity die casting makes it possible to manufacture items with complicated inner shapes in a cost effective way in small and medium quantities.

Products show

Related Keywords