HDSN Double-suction Split Case Centrifugal Pump

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30-60 Days

- Transportation:

- Ocean

- Port:

- Tianjin In China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shijiazhuang |

|---|---|

| Supply Ability: | 30 Set/Month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean |

| Port: | Tianjin In China |

HDSN Double-suction Split Case Centrifugal Pump

• Product Introduction

HDSN series double suction pump is single-stage centrifugal horizontal split pump.The greatest feature of this pump is: wide-range performance, high efficiency, compact construction, reliable operation, easy maintenance and long service life.

This product is often used as a water intake pump or circulating pump widely applicable to tap water, irrigation, pump station system, power station circulating water system, industrial water supply system, fire protection system, Marine industry and petrochemical industry and other fields.

• Product Feature

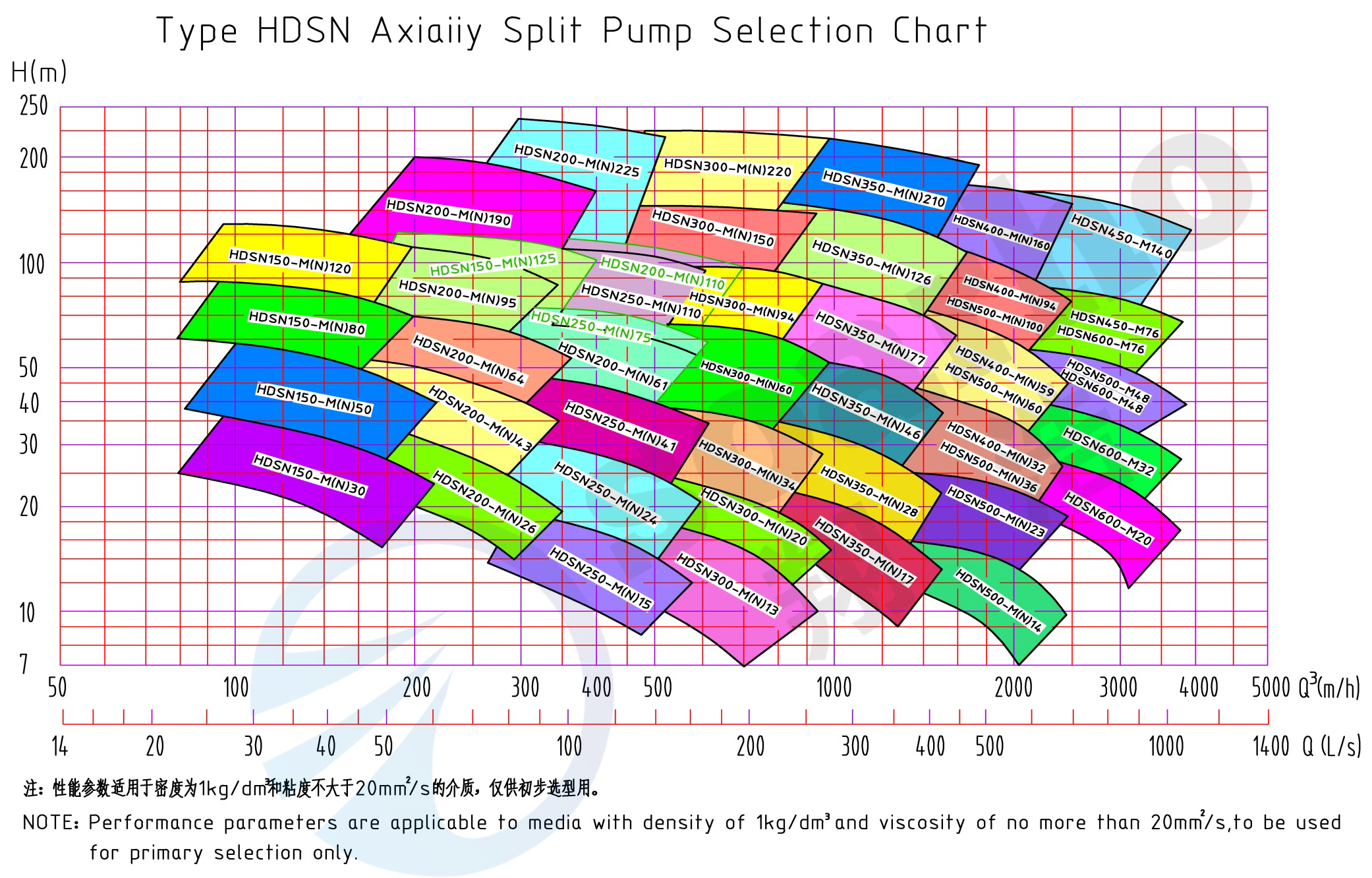

1.Wide range of performance: According

to the required performance points, the prototype impeller (M type), the

modified impeller (N type) and its cutting impeller can be used.

2. Excellent

absorptive capacity:This series of double

suction pumps have excellent absorption capacity, excellent cavitation

performance and can operate at high speed.

3.Diversity of material:In addition to the standard materials, this

series of pumps are made of various materials suitable for different media.

Including gray iron, ductile iron, cast steel, stainless steel and other

materials.

4.Smooth operation, low vibration, low noise:The impeller adopts double suction structure,

and the pump body adopts double worm shell structure. The axial force is

reduced to the minimum, and the distance between bearings is shortened as far

as possible, so as to reduce vibration and noise.

5.Easy maintenance:This axially split pump provides convenience for

the maintenance of the rotor part (including bearing, sealing and other

vulnerable parts). It can be operated by simply opening the pump cover, without

disconnecting the inlet and outlet pipelines, couplings and even motors.

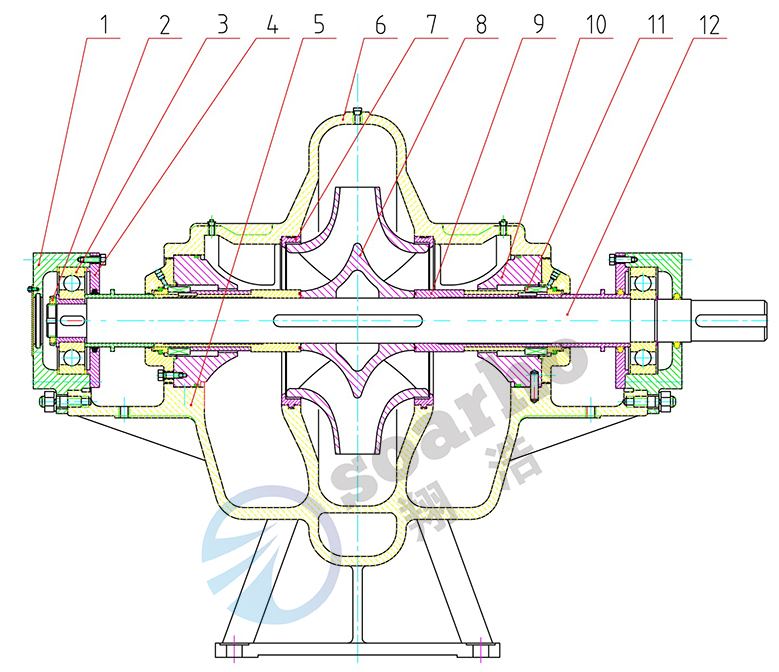

1 Bearing body 2 Rround nut 3 Bearing 4 Bearing cover

5 Pump casing 6 Pump cover 7 Sealing ring 8 Impeller

9 Shaft sleeve 10 Sealing body 11 Sealing component 12 Shaft

• Range of Performance

Capacity Q:68-3975m3/h

Head H:6-230m

Discharge diameter: 150-600mm

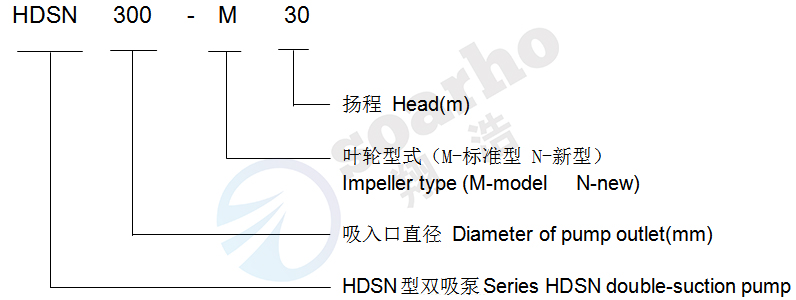

• Model Code

• Performance List

See the attachment.

Related Keywords