250 WND Dredging Pump

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean

- Port:

- Tianjin In China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shijiazhuang |

|---|---|

| Supply Ability: | 30 Set/Month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean |

| Port: | Tianjin In China |

250WND Dredging Pump

• Product Introduction

250WND dredging pump is horizontal centrifugal slurry pump.Compared with 250WN,250WND head is lower,impeller channel is wider and the maximum passing particle size is larger. This pump is simple and reliable in structure, easy to disassemble and maintain, and adopts high chrome cast iron parts,which has a long trouble-free life.The pump is sand dredge pump for dredging of river and sea. The flow passage of the impeller is wide through the capacity, so it is difficult to block for pumping sand gravel or high plastic clay. It has super strong excavation and suction ability.

250WND is suitable for dredging and filling operations of cutter-suction dredger and trailing suction dredger. It is also used as river sand dredged pump and mine slurry pump.

• Product Feature

1.The structure is simple and reliable.

The pump adopts single pump casing structure. According to the connecting way of gear box can provide two kinds of typical structures, one is connected with own bearing bracket, the other is combined with reduction gear box. The lubrication of pump with bearing bracket is grease lubrication or thin oil lubrication.

2. Easy to assemble and disassemble and easy to maintain. The front dismantling structure is adopted, and special disassembly tools are equipped to facilitate disassembly and assembly.

3.The performance of dredging is excellent. The flow and head curve of the pump are steep, the suction ability is strong, the ability of passing the pump is good, the change of the distance is more applicable, and the depth of digging and the higher transportation concentration can be reached.

4.Good wear resistance and long life of flow high chrome cast iron parts. The impeller, volute liner, throat bushing and rear plate liner (wearable liner) are made of strong wear resistant alloy cast iron whose hardness is not less than 58HRC.It has not only impact on resistance but also high anti-abrasion performance.

5.Using advanced hydraulic model, the pump has low hydraulic loss, high efficiency and low energy consumption. The service life of each wear part is full considered in the process of product design. The same replacement cycle reduce the maintenance and replacement costs.

6.The shaft seal is reliable and no leakage.

The pump adopts mechanical seals or packing seals or combination of mechanical and packing seals.

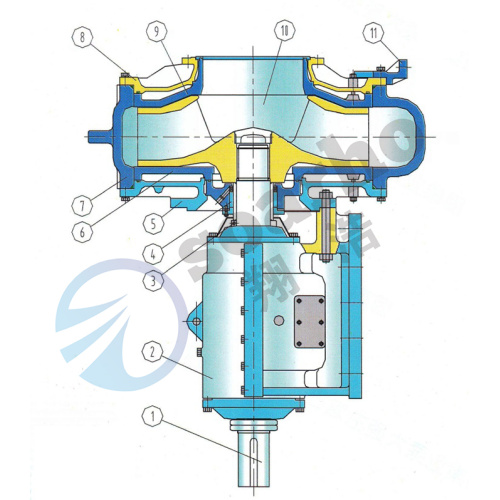

Structure 1 250WND combined with gear box structure

1 Gear box

2 Impeller release collar

3 Seal assembly

4 Adaptor plate

5 Rear plate liner

6 Frame plate

7 Cover plate

8 Throat bushing

9 Impeller

10 Supporting plate

1 Shaft

2 Support

3 Impeller release collar

4 Seal assembly

5 Adaptor plate

6 Rear plate liner

7 Frame plate

8 Cover plate

9 Throat bushing

10 Impeller

11 Supporting plate

• Range of Performance

Capacity Q:900-1100m3/h

Head H:20-40m

Discharge diameter: 250mm

Related Keywords