10kg Loading BOPP D-cut Rice PP Bag

- Payment Type:

- L/C, T/T, D/P, Paypal

- Incoterm:

- FOB, CFR, CIF, EXW, FCA

- Min. Order:

- 20000 Bag/Bags

- Min. Order:

- 20000 Bag/Bags

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin, Qingdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 3000,000pcs per month |

| Supply Ability: | on time delivery |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Certificate: | ISO9001, SGS, FDA, RoHS |

| HS Code: | 6305330090 |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,Qingdao,Shanghai |

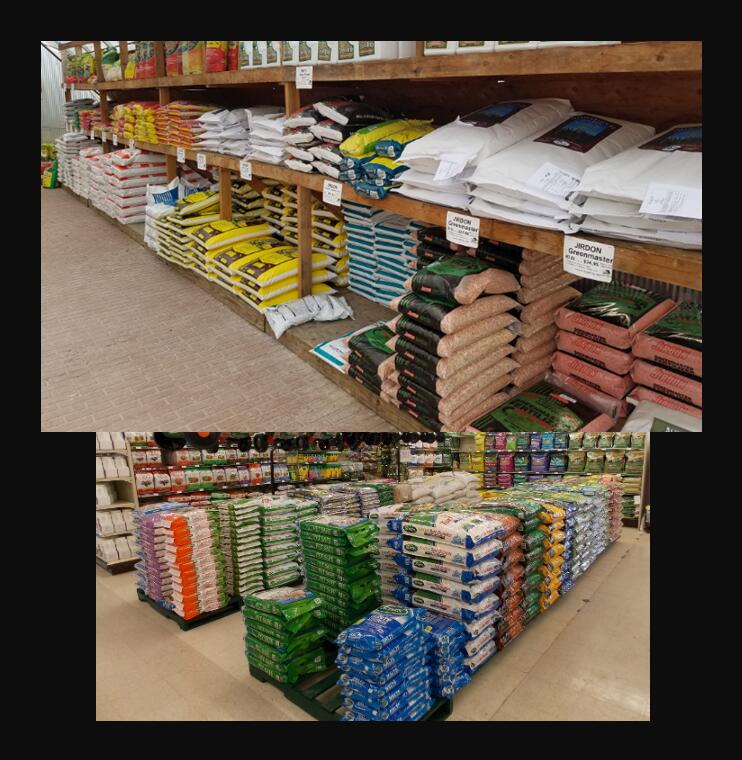

BOPP laminated bags are an excellent medium for high impact graphics and presentation with photographic reproduction, in either high-gloss, matt-finish, metalised or pearlised finishes. They can be produced with or without UV stabilisation.

Utilizing high quality graphics with up to 8 colours, including process half-tone printing (photographic quality), this gives superior brand presentation. The process achieves this by printing on the inner side of the BOPP film, with inks secured during the lamination process; effectively sandwiched between the WPP fabric & the BOPP film, and thus preventing the brand from scuffing or rubbing off and ensuring a high quality presentation for the life of the bag, i.e.: WPP bags laminated with BOPP (gloss or matt) film with high quality photographic printing for the ultimate presentation.

Product Specifications:

Fabric Construction: Circular PP Woven fabric (no seams) or Flat WPP fabric (back seam bags)

Laminate Construction: BOPP Film, glossy or matte

Fabric Colors: White, Clear, Beige, Blue, Green, Red, Yellow or customized

Laminate Printing: Clear film printed using 8 Color technology, gravure print

UV Stabilization: Available

Packing: From 500 to 1,000 Bags per Bale

Standard Features: Hemmed Bottom, Heat Cut Top

Optional Features:

Printing Easy Open Top Polyethylene Liner

Anti-slip Cool Cut Top Ventilation Holes

Handles Micropore False Bottom Gusset

Sizes Range:

Width: 300mm to 700mm

Length: 300mm to 1200mm

How to produce a BOPP bag

BOPP bag has different layers in the bag and they are also known as Multi layer bag, HDPE/PP woven fabric is one of the layer in the bag, Firstly we prepare a multi colored BOPP films through engraved cylinders and Rotogravures reverse printing technology. Then it is laminated with HDPE/PP woven fabrics and finally the cutting and stitching is done as per the requirements.

The printing process is done through engraved cylinders and Rotogravures reverse printing technology, up to 8 colors can be printed on the single Bag , we have got a graphic department , they develop various customized designs for the particular product with the specific images and back ground colors etc , once the designs are finalized the cylinders are engraved to print the same.

Our company

Boda is one of China’s top packaging producers of specialty Polypropylene Woven Bags. With world-leading quality as our benchmark, our 100% virgin raw material, top-grade equipment, advanced management, and dedicated team allow us to supply superior bags all over the world.

Our company covers an area totally of 160,000 square meters and there are more than 900 employees. We possess a series of advanced Starlinger equipment including extruding, weaving, coating, laminating and bag produce. What’s more, we are the first manufacturer in domestic that imports the AD* STAR equipment in the year 2009 for Block Bottom Valve Bag Production.

Certification: ISO9001, SGS, FDA, RoHS

Related Keywords