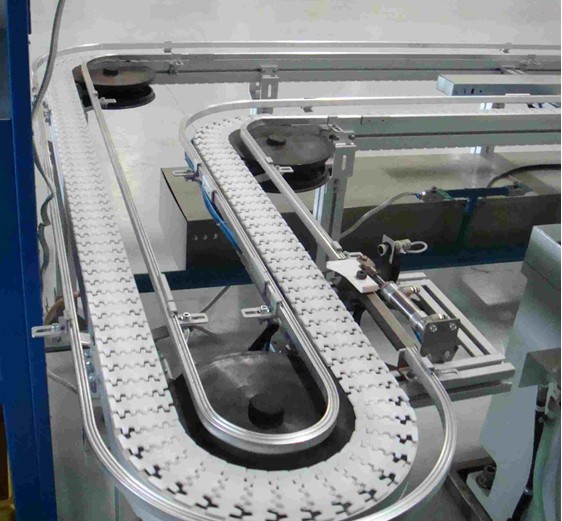

Flexible chain conveyor system

- Payment Type:

- L/C, T/T, Paypal, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Delivery Time:

- 10 Days

- Transportation:

- Ocean, Land, Air

- Port:

- TianJin, GuangZhou, QingDao

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,Paypal,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportation: | Ocean,Land,Air |

| Port: | TianJin,GuangZhou,QingDao |

Structure and characteristics

Flexible chain conveyor, also called flexible conveyor, is a kind of chain conveyor. It is smart and beautiful, easy to install, standard structure, clean and pollution-free. Flexible chain conveyor is widely used in food, medicine, cans. Beverages, paper products, dairy, cosmetics, tobacco and other industries with stricter hygiene requirements.

1.The flexible chain conveyor can automatically carry out transportation, distribution and continuous transportation of subsequent packaging. It is the best choice for enterprises to highly automated division of labor and improve production efficiency.2.The flexible chain conveyor can carry out a variety of conveying methods according to different product types, such as clamping, hanging, dragging, and pushing; it can also set merge, split, aggregate, and sub-inspection according to the choice of function, and according to the needs of the product production process , To form a conveying system suitable for product conveying and production.

Features

(2) Quiet: equipment running sound <30Db.

(3) Smart: a flexible conveyor system assembled from arbitrarily disassembled components, with vertical and horizontal curves of different radii, can transport products in any 3D space, and can be carried out according to your production status anytime, anywhere Adjustment.

(4) Convenience: No special tools are required for the installation of the whole line, and only common hand tools are needed to complete the basic disassembly and assembly work by a single person.

(5) Stability: Stable performance can ensure that the delivered product does not tip over and slip off during transportation.

Specifications

2. The maximum conveying length of a single drive head: 25M;

3. Working temperature: -20℃~+80℃;

4. The highest conveying speed: 50M/min;

5. Chain pitch: 25.4 -38.1mm;

6. Minimum turning radius: R150mm;

7. Tensile strength: 4000N;

8. Chain plate weight: 0.7KG/M.

Related Keywords