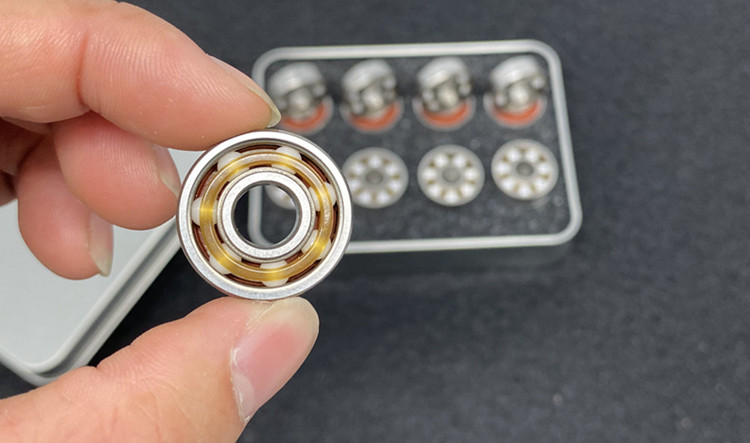

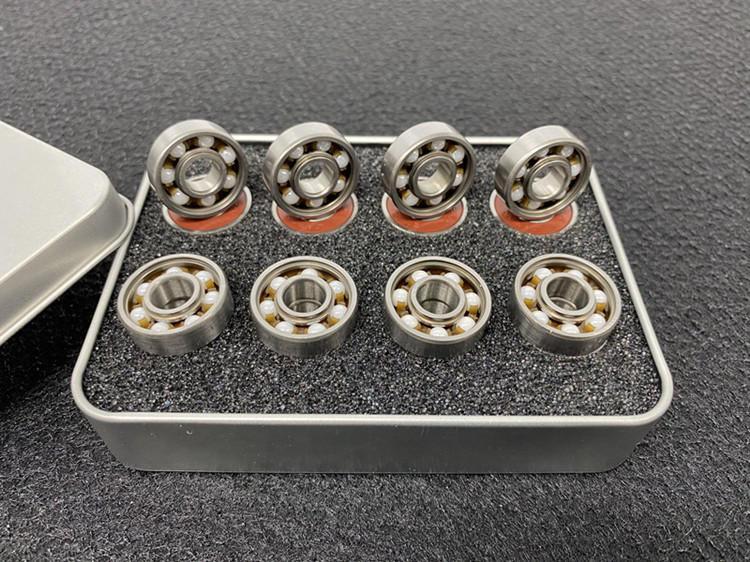

608 full ceramic ball bearings

-

$2.991-99 Set/Sets

-

$2.85100-999 Set/Sets

-

$2.65≥1000 Set/Sets

- Transportation:

- Express, Ocean, Land, Air

- Port:

- Qingdao Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Productivity: | 500 pieces per day |

| Supply Ability: | 1000000 Set/Sets per Month |

| Payment Type: | L/C,D/A,D/P,T/T,Western Union,MoneyGram |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | supply |

| HS Code: | ask |

| Transportation: | Express,Ocean,Land,Air |

| Port: | Qingdao Port |

608 full ceramic ball bearings

Ceramic Hybrid Bearings have Steel races and Ceramic Balls. Ceramic Balls are suitable for applications where high loads, high speeds and extreme temperatures are factors. Long life and the need for minimal lubrication make this material appropriate for extreme applications. Ceramic is non-porous, non-magnetic, non corrosive and lighter than steel. In ball form, ceramic balls are also harder than steel and because ceramic balls are non-porous they are virtually frictionless and capable of spinning faster than steel balls.

Ceramic Balls are usually made of following materials:Silicon Nitride (SiN4)

Alumina Oxide (Al2O3)

Zirconia Oxide (ZrO2)

Silicon Carbide (SiC)

Because ceramic is a glass like surface it has an extremely low coefficient of friction and is ideal for applications seeking to reduce friction. Ceramic balls require less lubrication and have a greater hardness than steel balls which will contribute to increased bearing life. Thermal properties are better than steel balls resulting in less heat generation at high speeds.

As an important mechanical foundation, ceramic bearing has better performance than metal bearing, and its high temperature resistance and super strength are the first in the world of new materials. it has been widely used in

various fields of national economy and people's livelihood.

Ceramic Hybrid Bearings Advantage

1.because ceramics are hardly afraid of corrosion, ceramic rolling bearings are suitable for working under harsh conditions full of corrosive media.

2.because the ceramic rolling ball has a lower density than steel and is much lighter in weight, the centrifugal effect of the

outer ring can be reduced by 40% when rotating, thus greatly extending its service life.

3.ceramics are less affected by heat expansion and cold shrinkage than steel, so the bearing can be allowed to work in an

environment where the temperature difference changes dramatically when the bearing clearance is constant.

4.as the elastic modulus of ceramics is higher than that of steel, it is not easy to deform under stress, so it is beneficial

to improve working speed and achieve higher accuracy.

Ceramic Hybrid Bearings Classification

1.ZrO2(Full Ceramic)

The ferrule is made of zirconia (ZrO2) ceramic material, the holder is made of PTFE (PTFE) as the standard configuration, and the glass fiber reinforced nylon 66 (rpa66-25), special engineering plastics (PEEK, PI), stainless steel (AISISUS316), brass (Cu) etc.

2.Si3N4(Hybrid ceramic)

Si3N4 ceramic material is used for bearing ring and rolling of silicon nitride (Si3N4). The SiN4 all ceramic bearings are suitable for higher speed, load capacity and higher ambient temperature than the ZrO2 materials.

OUR MAIN PRODUCTS

1.Deep Groove Ball Bearing

2.Self-aligning Ball Bearing

3.Cylindrical Roller Bearing

4.Sphercial Roller Bearing

5.Angular Contact Ball Bearing

6.Tapered Roller Bearing

7.Auto Engine Valve

8.Auto Parts Piston And Ring

9.Pillow Block Bearing

10.Skf Deep Groove Ball Bearing

11.Auto Parts Timing Chain Kits

If you have any request for Clutch Bearing,please chat with us in your free time!!

Related Keywords